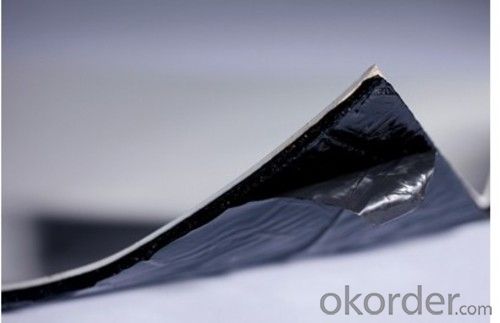

EPDM Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

Application:

1) Make sure the roof deck smooth,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2) There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3) After application,a full serious inspection is required to make sure no air bubble,no fold,no falling away etc to guarantee the waterproof life

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be used on precast concrete block surfaces?

- Precast concrete block surfaces can benefit from the application of a waterproofing membrane. These membranes are commonly used to safeguard below-grade structures, like basements and foundations, from water infiltration. When constructing these structures, precast concrete blocks are frequently utilized, and the use of a waterproofing membrane can prevent water from seeping into the concrete and causing harm. The membrane acts as a barrier, prohibiting water from passing through while still allowing the concrete to breathe and release any accumulated moisture. Furthermore, waterproofing membranes can enhance the overall durability and lifespan of precast concrete blocks by shielding them from moisture-related problems such as cracking, spalling, and corrosion. It is crucial to select a waterproofing membrane that is specifically designed for below-grade applications and is compatible with concrete surfaces to ensure proper adhesion and long-term efficacy.

- Q:What is the best waterproofing membrane for my project?

- The choice of the best waterproofing membrane for your project will depend on various factors, such as the project type, specific requirements, and budget. There are multiple options available in the market, each offering unique features and advantages. One favored option is the bituminous waterproofing membrane, which is cost-effective and suitable for a wide range of projects like roofs, basements, and foundations. These membranes are durable, flexible, and can withstand extreme weather conditions. They can be applied using methods like torch-on, self-adhesive, or hot-melt. Another alternative to consider is the polyurethane liquid membrane, which provides exceptional elasticity and is ideal for areas requiring flexibility, such as balconies, terraces, and swimming pools. These membranes are resistant to UV rays and can be easily applied using a brush or roller. For projects that demand high durability and resistance, the cementitious waterproofing membrane might be the optimal choice. This type of membrane is a mixture of cement, sand, and special additives that create a thick and protective layer. It is commonly used for underground structures, tunnels, and water tanks. If your project involves below-grade applications or areas with high water pressure, the bentonite waterproofing membrane could be the most suitable option. Bentonite membranes, made of clay minerals, swell when exposed to water, forming a watertight barrier. They are commonly used in basements, foundations, and retaining walls. Ultimately, determining the best waterproofing membrane for your project will depend on your specific requirements, budget, and preferences. It is advisable to consult with a professional waterproofing contractor who can assess your project's needs and recommend the most suitable membrane system.

- Q:Can a waterproofing membrane be applied on top of existing surfaces?

- Yes, a waterproofing membrane can be applied on top of existing surfaces. However, it is important to ensure that the existing surface is clean, dry, and free from any contaminants or loose materials before applying the membrane. Additionally, proper surface preparation and application techniques should be followed to ensure the effectiveness and longevity of the waterproofing system.

- Q:Can a waterproofing membrane prevent mold and mildew growth?

- A waterproofing membrane has the ability to prevent the growth of mold and mildew. Mold and mildew thrive in areas that are damp and moist, but waterproofing membranes act as a barrier that stops water from seeping into the surfaces below. By ensuring that the area remains dry, the membrane reduces the conditions needed for mold and mildew to grow. Furthermore, certain waterproofing membranes are specifically designed to have antimicrobial properties, which further hinder the growth of mold and mildew. However, it is important to remember that while a waterproofing membrane can help prevent mold and mildew growth, it is not a guaranteed solution. Proper ventilation and maintenance are also essential in preventing these problems.

- Q:Can a waterproofing membrane be used on underground parking structures?

- Yes, a waterproofing membrane can be used on underground parking structures. In fact, it is highly recommended to have a waterproofing system in place to protect the structure from water ingress and potential damage. Underground parking structures are prone to water infiltration due to their below-ground level and close proximity to the water table. A waterproofing membrane acts as a barrier against water, preventing it from seeping into the structure and causing issues such as deterioration, corrosion, and mold growth. It helps to maintain the structural integrity of the parking facility and prolong its lifespan. Additionally, a properly installed waterproofing membrane can also provide protection against other sources of moisture, like rainwater runoff or groundwater. Overall, using a waterproofing membrane is a crucial step in ensuring the long-term durability and functionality of underground parking structures.

- Q:How is a waterproofing membrane installed?

- Installing a waterproofing membrane typically involves a step-by-step process to ensure proper installation and effective waterproofing. Here is a general overview of how a waterproofing membrane is installed: 1. Surface Preparation: The first step is to prepare the surface where the membrane will be installed. This involves cleaning the surface thoroughly and removing any dirt, debris, or loose materials. It is essential to create a clean and smooth surface for optimal adhesion of the membrane. 2. Priming: Next, a primer is applied to the surface. The primer helps improve adhesion between the membrane and the substrate. It also provides a uniform surface for the membrane to adhere to. 3. Membrane Application: The waterproofing membrane is then applied to the prepared surface. There are different types of membranes available, such as sheet membranes or liquid-applied membranes. Sheet membranes are typically rolled out onto the surface and adhered using a suitable adhesive or self-adhesive backing. Liquid-applied membranes are spread or sprayed onto the surface in multiple coats, allowing each coat to cure before applying the next one. 4. Seam and Joint Treatment: In areas where multiple sheets or sections of the membrane meet, seams and joints are treated to ensure a watertight seal. This may involve overlapping the sheets and applying a seam tape or using a liquid-applied sealant to fill any gaps or joints. 5. Protection and Drainage: Once the membrane is installed, it is essential to protect it from damage and provide proper drainage. This can be achieved by installing a protective layer, such as a geotextile fabric or a drainage board, over the membrane. These layers help prevent punctures or abrasions and allow any water that penetrates the surface to drain away effectively. 6. Quality Control: After the installation is complete, it is crucial to perform quality control checks to ensure the membrane has been installed correctly. This may involve visual inspections, conducting water tests, or using specialized equipment to test the integrity of the membrane. It is important to note that the specific installation process may vary depending on the type of waterproofing membrane used and the requirements of the project. It is recommended to follow the manufacturer's guidelines and consult with a professional waterproofing contractor for accurate installation instructions.

- Q:How does a waterproofing membrane ensure a watertight seal around penetrations?

- A waterproofing membrane ensures a watertight seal around penetrations by providing a protective barrier that prevents water from seeping through gaps or openings. It is designed to adhere tightly to the surface, creating a seamless and impermeable layer that seals off any potential entry points for water. This membrane acts as a shield, effectively preventing moisture from penetrating the structure and causing damage or leakage.

- Q:Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Waterproofing membranes are designed to withstand a wide range of temperatures and are often used in both hot and cold climates. They are engineered to be flexible and durable, allowing them to effectively protect against water intrusion and withstand temperature fluctuations without losing their effectiveness.

- Q:Are waterproofing membranes resistant to mineral oils?

- Yes, waterproofing membranes are generally resistant to mineral oils.

- Q:Can waterproofing membranes be used in swimming pools?

- Yes, waterproofing membranes can be used in swimming pools. They are commonly used to create a waterproof barrier that prevents water from seeping through the pool walls or floor, ensuring the pool remains watertight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords