Easy Removal Plastic Formwork Wall Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic formwork

Plastic Formwork Concrete Formwork New Material

Saving your time, money and energy !!!

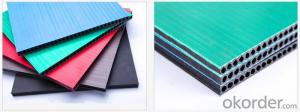

The material of modular formwork is ABS mixied with special glass fibres which enable panels to hold high pressures.

The handles are made by high strength Nilon, each panel locked by at least 5 handls, which makes the whole system strong enough to pour 40cm walls.

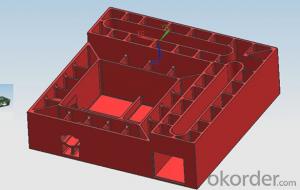

What is Details of our products plastic concrete formwork ?

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

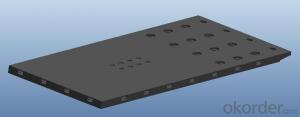

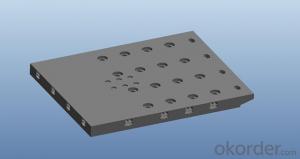

Product Photos/ plastic concrete formwork

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price.

Please send your project design drawing in AutoCAD file to us, we will help to make formwork solution for you.

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q:Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q:I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q:Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q:Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q:Will the plastic building template on the builders really do not use the price is how much price

- Low foaming high strength plastic building template. The template rigid plastic combination, high strength, light weight, impact strength, can be sawable nail can be welded, industrial temperature up to -15 ℃ to 75 ℃ can be applied without cracking. 10 meters high vertical drop does not break, can be used 40 times to 100 times, waste plate can be recycled, more than 30% of the cost savings than the wood template, is the twenty-first century to plastic and wood ideal plastic building template.

- Q:We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q:Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Personally feel that PVC sheet deformation has more reasons. The main reasons are as follows.Pvc plate deformation are: physical deformation and chemical deformation.1. Physical deformation, cause:High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems. Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the root causes.2. Chemical deformation: mainly the molecular structure of raw materials change.

- Q:Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q:Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Easy Removal Plastic Formwork Wall Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords