E-glass Fiberglass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

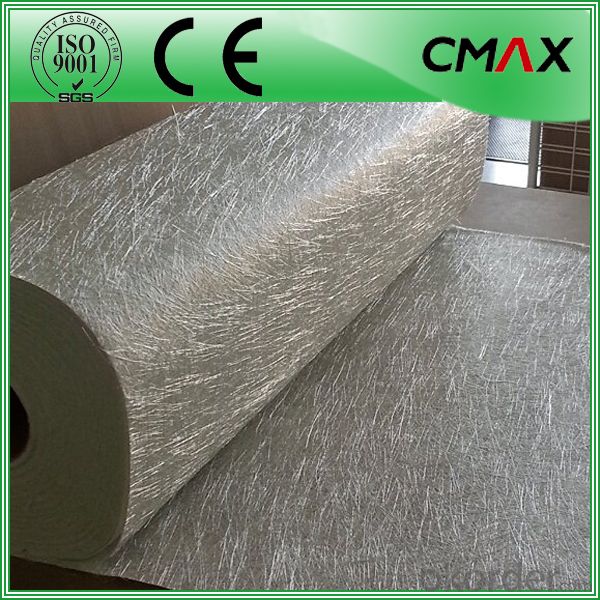

E-glass Fiberglass Chopped Strand Mat Factory

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

Products Shows:

Certificates:

- Q:Are there any health concerns associated with fiberglass facing?

- Yes, there are some health concerns associated with fiberglass facing. Fiberglass is made of tiny fibers that can become airborne and if inhaled, they can irritate the respiratory system. Prolonged exposure to fiberglass can lead to respiratory issues, such as coughing, wheezing, and even a condition called fiberglass lung. It is important to take proper precautions, such as wearing protective gear and working in well-ventilated areas, when handling fiberglass to minimize the health risks.

- Q:How is fiberglass facing installed?

- Fiberglass facing is typically installed by positioning it against the desired surface and securing it with adhesive or mechanical fasteners such as staples or screws. The facing is then smoothed out to remove any wrinkles or air bubbles, ensuring a tight and even installation.

- Q:Does fiberglass facing help with soundproofing?

- Fiberglass facing is capable of aiding in soundproofing. Fiberglass possesses remarkable sound-absorbing capabilities, effectively capturing and diminishing sound waves. By utilizing fiberglass as a facing material, the soundproofing attributes of a wall or ceiling can be enhanced, minimizing noise transmission. The facing functions as a barrier, effectively preventing sound from traversing through, rendering it an efficient solution for reducing noise pollution in diverse environments, including residences, workplaces, studios, and industrial settings. Moreover, fiberglass is lightweight, simple to install, and can be effortlessly combined with other soundproofing materials to achieve superior outcomes.

- Q:How does fiberglass facing contribute to energy efficiency in buildings?

- Fiberglass facing contributes to energy efficiency in buildings by acting as a thermal insulator. It helps to reduce heat transfer through the walls, ceilings, and floors of a building, leading to improved energy conservation and lower utility bills. Additionally, fiberglass facing can also provide an effective barrier against air infiltration, reducing drafts and improving indoor air quality.

- Q:Can fiberglass facing be used in high-temperature applications?

- No, fiberglass facing cannot be used in high-temperature applications. Fiberglass is a type of reinforced plastic material that is known for its excellent thermal insulation properties and resistance to corrosion. However, it has a low melting point and is not suitable for use in high-temperature environments. When exposed to high temperatures, fiberglass can melt, warp, or degrade, compromising its structural integrity and insulation properties. Therefore, it is important to choose alternative materials specifically designed for high-temperature applications, such as ceramic fiber or metal facing, to ensure safety and optimal performance.

- Q:Can fiberglass facing be painted or customized?

- Yes, fiberglass facing can be painted or customized.

- Q:What are the potential drawbacks of using fiberglass facing?

- One potential drawback of using fiberglass facing is its susceptibility to damage and breakage. Unlike other materials like metal or concrete, fiberglass can be easily cracked or shattered if not handled with care. Another drawback is that fiberglass facing is not as strong or durable as some alternative materials, which could limit its use in certain applications that require higher strength or resistance to extreme conditions. Additionally, fiberglass can be more expensive compared to other materials, which may impact the overall cost of a project.

- Q:Does fiberglass facing require regular maintenance?

- Regular maintenance is not required for fiberglass facing. Fiberglass is a resilient material that can resist various environmental elements, such as moisture, UV rays, and pests. Unlike other materials, it doesn't corrode, rot, or decay, eliminating the need for frequent painting or sealing. Nevertheless, it's crucial to keep the fiberglass facing clean and clear of dirt and debris to preserve its appearance and performance. To maintain its good condition, regular cleaning with mild detergent and water should suffice. Additionally, prompt repair of any damage or cracks in the fiberglass facing is necessary to prevent further complications. In conclusion, fiberglass facing is a low-maintenance choice that can endure for many years with minimal upkeep.

- Q:Is not the multi-layer membrane waterproof, the bottom of the membrane should use glass fiber mats?

- In the yin and yang angle additional layer construction better fit, polyester tire waterproofing membrane tires hard

- Q:Is fiberglass facing resistant to moisture or water damage?

- Yes, fiberglass facing is resistant to moisture and water damage. Fiberglass is composed of fine glass fibers woven together, which creates a strong and durable material. These fibers do not absorb moisture, making fiberglass facing highly resistant to water damage. It is commonly used in applications where moisture or water exposure is expected, such as in bathrooms, kitchens, and outdoor areas. Additionally, fiberglass facing is also resistant to mold and mildew growth, further enhancing its ability to withstand moisture.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords