Duct Iron Pipe DI Pipe ISO 2531 DN 1100-2000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

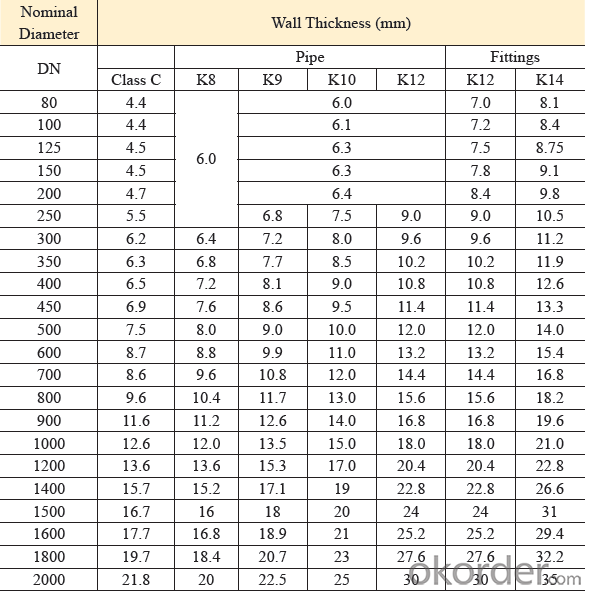

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

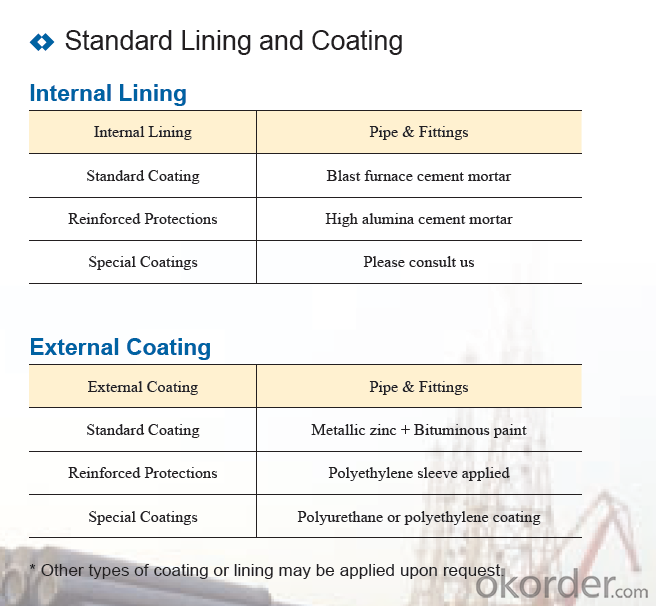

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

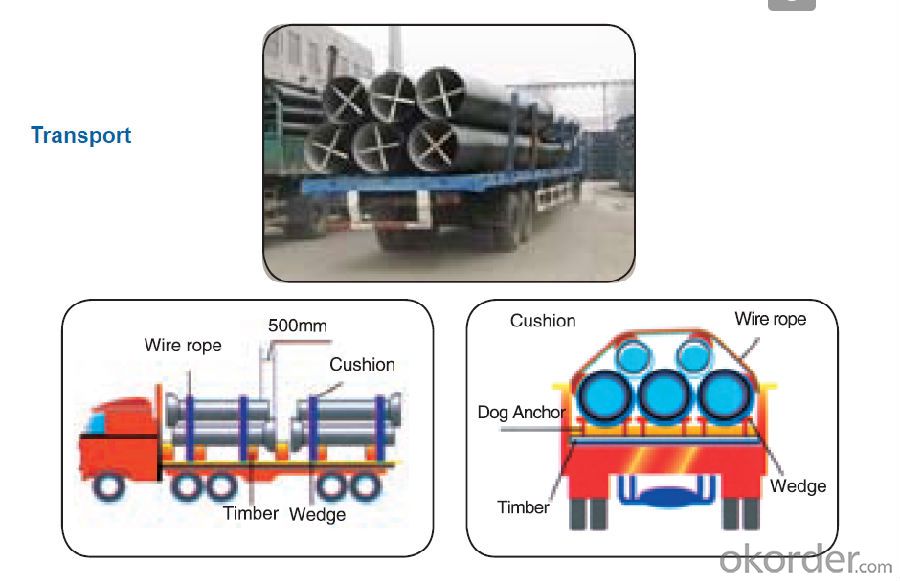

Transport:

- Q:Can ductile iron pipes be used for wastewater reuse projects?

- Ductile iron pipes are suitable for wastewater reuse projects due to their various properties. Firstly, they possess high strength and durability, enabling them to withstand the pressure and load requirements of wastewater systems. Additionally, they exhibit outstanding corrosion resistance, a crucial factor in wastewater applications where the presence of chemicals and corrosive substances is common. Moreover, the smooth internal lining of ductile iron pipes reduces friction and enhances the flow of wastewater. This is essential for efficient transportation and distribution of wastewater in reuse projects. Furthermore, ductile iron pipes are renowned for their ease of installation and maintenance. They can be effortlessly connected using various joint options, facilitating quick and efficient installation. Additionally, their long service life reduces the necessity for frequent replacements and minimizes maintenance costs. In conclusion, the properties of ductile iron pipes make them a suitable option for wastewater reuse projects, providing strength, durability, corrosion resistance, smooth flow, and ease of installation and maintenance.

- Q:Does the cast iron have size 250? What's the performance?

- You should be the casting grade or material, if it is ductile iron, said generally between QT400-15 or QT700-2 different indicators, said in front of the tensile strength, the elongation rate refers to the back, China is now the lowest grade of nodular cast iron material is QT400-15, such as QT250.In addition, the number 250 you refer to may also be a code name for ductile iron parts, such as 200, 300, etc., which are manufactured by the factory as required by the project.Gray iron, which has a 250 brand, is generally referred to as HT250, but it is not ductile iron.The machine on the ductile iron and gray iron are used, but generally not made of grey cast iron gear

- Q:What are the different accessories available for ductile iron pipe?

- There are several accessories available for ductile iron pipes that help enhance their functionality and ensure efficient operation. Some of the common accessories include: 1. Flange Adapters: These accessories help connect ductile iron pipes to other pipe materials or equipment such as valves, pumps, or fittings. Flange adapters provide a secure and leak-proof connection. 2. Mechanical Joint Fittings: Mechanical joint fittings are used to join ductile iron pipes together. They consist of a gland, gland follower, and bolts, providing a flexible and easily adjustable connection. 3. Restrained Joint Fittings: These fittings are used in applications where the pipe needs to be restrained to prevent movement or separation. They ensure stability and prevent potential damage from external forces or pressure. 4. Thrust Blocks: Thrust blocks are concrete structures used to resist the thrust generated by internal pressure in ductile iron pipes. They prevent pipe movement and maintain stability. 5. Valve Boxes: Valve boxes provide protection and easy access to valves installed along the ductile iron pipeline. They are typically made of cast iron or polymer materials and are available in various sizes and designs. 6. Hydrant Assemblies: Hydrant assemblies are installed for fire protection purposes. They consist of a ductile iron pipe, a hydrant valve, and a fire hydrant. These assemblies are crucial for quick access to water during firefighting operations. 7. Tapping Saddles: Tapping saddles are used to create a branch connection on a ductile iron pipe without interrupting the flow. They provide a convenient way to install service connections, valves, or meters. 8. Pipe Restraints and Supports: These accessories are used to secure ductile iron pipes to structures or prevent excessive movement. They help maintain proper alignment, prevent sagging, and ensure the structural integrity of the pipeline. 9. Pipe Repair Clamps: In case of pipe damage or leaks, repair clamps provide a quick and temporary solution. These clamps are designed to fit around the damaged area and provide a tight seal to stop the leak. 10. Gaskets and Seals: Gaskets and seals are essential accessories to ensure leak-free connections. They are available in various materials, such as rubber or synthetic compounds, and are used to create a watertight seal between pipes or fittings. These are just a few examples of the accessories available for ductile iron pipes. The selection of accessories depends on the specific requirements of the project, and consulting with a pipe supplier or engineer is recommended to ensure the right accessories are chosen for the application.

- Q:What is the cost of ductile iron pipes compared to other pipe materials?

- The cost of ductile iron pipes can vary depending on various factors such as size, length, and supplier. However, in general, ductile iron pipes tend to be more expensive compared to other pipe materials such as PVC (polyvinyl chloride) or steel. This is mainly due to the manufacturing process and the inherent qualities of ductile iron that make it a durable and reliable choice for various applications. Ductile iron pipes are known for their high tensile strength, resistance to corrosion, and durability, making them suitable for carrying potable water, wastewater, and other fluids under high pressure. The production process of ductile iron involves adding magnesium to cast iron, which results in improved strength and flexibility. This additional process, along with the quality of the material, contributes to the higher cost. On the other hand, pipes made from materials like PVC or steel can be less expensive. PVC pipes are lightweight, easy to install, and relatively inexpensive, making them a popular choice for low-pressure applications such as irrigation or drainage systems. Steel pipes, known for their strength and durability, are often used in high-pressure applications but come at a higher cost than PVC. Ultimately, the cost of ductile iron pipes may be higher initially, but their longer lifespan and reliability can offset the investment over time. Additionally, factors such as the specific project requirements, local regulations, and availability of materials can also influence the overall cost comparison between ductile iron pipes and other pipe materials.

- Q:Can ductile iron pipes be used for both water and sewer applications?

- Ductile iron pipes are versatile and can be utilized for water and sewer purposes. These pipes exhibit remarkable durability and exceptional corrosion resistance, rendering them appropriate for transporting both drinkable water and wastewater. Furthermore, they possess the ability to endure high pressure and resist external loads, making them a perfect fit for underground installations. Additionally, these pipes boast a lengthy lifespan and necessitate minimal upkeep, thereby offering a cost-effective option for water and sewer systems.

- Q:Are ductile iron pipes resistant to seismic events?

- Generally, ductile iron pipes exhibit resistance to seismic events. Ductile iron, a form of cast iron known for its strength and durability, can withstand external forces, including those induced by seismic events like earthquakes. The design of ductile iron pipes allows for flexibility, enabling them to absorb and dissipate energy from seismic waves. This flexibility ensures the pipes remain intact despite ground movements and vibrations, preventing any breakage or cracking. Moreover, the joints of these pipes are designed to offer some level of flexibility, further enhancing their ability to withstand seismic events. Furthermore, the construction of ductile iron pipes involves thick walls, providing them with exceptional structural integrity. This strength reduces their susceptibility to damage during seismic events and ensures a consistent flow of fluids, such as water, even in extreme conditions. Nonetheless, it is crucial to recognize that the resistance of ductile iron pipes to seismic events can depend on various factors. These factors include the magnitude and proximity of the earthquake, the quality of installation and maintenance, and the specific design considerations for the pipeline system. Consequently, it is vital to adhere to proper engineering and construction practices to optimize the resilience of ductile iron pipes in areas prone to seismic activity.

- Q:Are ductile iron pipes resistant to impact damage?

- Yes, ductile iron pipes are highly resistant to impact damage due to their inherent strength and durability.

- Q:If the ductile iron pipe is broken, can we use rush repair?

- These specifications are also based on the outer diameter of the tube. In daily life, we may also encounter a pipeline rupture, or when it is on the road to repair, excavator accidentally hit PE, PPR water supply and drainage pipeline, as long as a little, can be used to repair the pipeline repair section.

- Q:How does ductile iron pipe handle traffic loads and vibrations?

- Due to its inherent strength and durability, ductile iron pipe is capable of effectively handling traffic loads and vibrations. The material properties of ductile iron, such as its high tensile strength and impact resistance, make it a dependable option for enduring heavy loads and vibrations caused by traffic. When exposed to traffic loads, ductile iron pipe has the capacity to distribute weight efficiently, minimizing stress concentrations and potential damage. Its flexible nature enables it to absorb and dissipate the forces exerted by traffic, preventing the formation of cracks or fractures. Furthermore, ductile iron pipe possesses the advantage of dampening vibrations. With its high density and stiffness, it can absorb and dissipate the energy generated by vibrations, lessening their impact on the pipe and surrounding infrastructure. This is especially crucial in areas with heavy traffic or construction activities, where vibrations are common. Moreover, ductile iron pipes are frequently designed and manufactured to meet industry standards and specifications, ensuring their ability to withstand expected traffic loads and vibrations. These pipes are commonly used in water distribution systems, sewers, and underground infrastructure, where they are subjected to various dynamic loads and vibrations. In conclusion, ductile iron pipe is an exceptional choice for managing traffic loads and vibrations due to its strength, flexibility, and capacity to dampen vibrations. Its consistent performance under these conditions makes it a preferred material for infrastructure projects, guaranteeing long-term durability and minimal impact on the pipe's structural integrity.

- Q:How to distinguish flexible and rigid interfaces between cast iron pipe joints

- Flexible connections can be kept watertight at any angle (lateral or vertical), and rigid, where the interface of a pipe is easy to crack if a slight earthquake is encountered

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 1100-2000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords