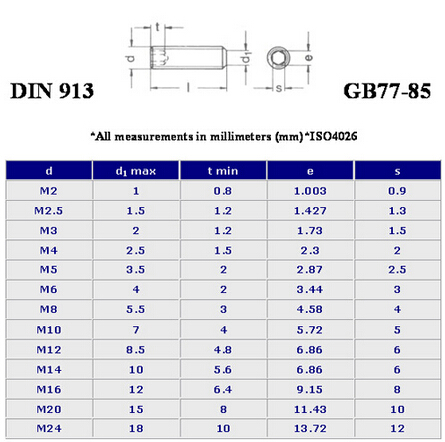

DIN913 Hexagon Socket Set Screws with Flat Point

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Name | DIN913 Hexagon Socket Set Screws with Flat Point |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M3--M8 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q:The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- The easiest way to change the place to hang the original place to hang a mural

- Q:When do flat washers use GB95 when using GB97.1?

- See tolerance, high requirements with GB97.1. if in order to save money, and the application environment is not high, use GB95.

- Q:What are the advantages and disadvantages of car audio modification, wood washer and plastic washer?

- The plastic washer is made of plastic, plastic washer at home, also known as plastic washers, washers (Washers) resin, plastic washer or nylon washer (the most common domestic market is mostly made of plastic washer nylon 66). Compared with metal gaskets, it has excellent insulation, corrosion resistance, thermal insulation and non magnetic properties, and light weight, widely used in semiconductor, automotive, aerospace industry and interior decoration and other fields. The number of materials used as many as 10 kinds, including PA66, PC, with the best performance of special engineering plastics PEEK, with glass fiber reinforced RENY and PPS, fluorine resin PTFE, PFA and PVD, etc..Wood washer to prevent resonance, but not waterproof.

- Q:What is the invention of the screw?

- Screws Today, many things are screwed together. Look around the house, the eyes see all kinds of things - from furniture to food processors, are connected with screws. The spirits were invented more than 2,000 years ago, but less than 500 years for fixing things. The first man who describes the spiral is the Greek scientist Archimedes (about 287 BC - 212 BC). The Archimedean spiral is a huge spiral in a wooden cylinder that is used to raise water from one level to another and irrigate the fields. Its true inventor may not be Archimedes himself. Maybe he just described something that already existed. Perhaps it was the ancient Egyptian craftsmen who had designed it to use the irrigation on both sides of the river. Archimedes spiral in the ancient society are used to raise water, no one considered to change it into a fixed piece. Right: Archimedes spiral is widely used for water. For example, the Romans used it to drain the mine. In the Middle Ages, carpenters used wooden nails or metal nails to connect furniture and wooden structures. In the 16th century, nail workers began to produce spiral nails, these nails can be more firmly connected things. It was a small step from this nail to the screw. At the end of the eighteenth century, screws were quite popular as fixed parts, because at that time a cheap production method had been found. Screwdriver (chisel) appeared in London around 1780 years.

- Q:Does the fastener include screws?

- A type of fastener with no head at both ends. At the end of the connection, it must be screwed into the part with the internally threaded hole and the other end through the part with the through hole and the nut is screwed even if the two parts are fastened together. This type of connection is called a stud connection and is also a detachable connection. Mainly used for one of the connected parts of a larger thickness, requiring a compact structure or due to the frequent removal of the bolt should not be used occasions.

- Q:Screw M is mechanical teeth, tapping is what?

- There are many kinds of tapping teeth, such as: triangular teeth, iron teeth, wood thread, etc. Usually used TP said

- Q:Gasket 300HV relative to what material?

- Due to the standard for the 100HV, 140HV flat washers can be made of low carbon steel. General enterprises in the selection of materials, most of the materials used in Baosteel, easy to cold stamping

- Q:I would like to look at my mp4 apart, the above screws are small, is cross-type, our family is not so small screwdriver, what can be used to screw the screw Oh, a little practical method Kazakhstan,

- Is there a special small screwdriver that is special, if it is not used to cause or nails sometimes.

- Q:Stud that head or nut that ah, I need to have the authority of the provisions of the document, please know that the prawns are told, thanks to!

- The main purpose of the elastic cushion is to prevent loosening, which is added at the end of the screw, and the screw nut is arranged on the side of the nut.

- Q:how to use Motor washer

- Halo, brother, your question also detailed ah, there are a lot of places on a motor washer ah, do you mean where ah, you have to iron or plastic washers, spring washers, I think it is the plastic washer, mainly plastic washer 1 are leak proof, waterproof, anti oil,... 2 insulation, high pressure resistance, 3, vibration reduction, 4, reduce wear, basically on these several functions

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIN913 Hexagon Socket Set Screws with Flat Point

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords