Decoration Gypsum Ceiling Board Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

* Material: Atlantis paper-faced gypsum board

* Thickness: 7mm, 7.5mm, 8.0mm, 8.5mm, 9.0mm, 9.5mm, 12mm, 12.5mm

* Sizes: 595x595mm, 600x600mm, 595x1195mm, 603x603mm, 605x605mm,603x1212mm, 610x1220mm(2’x 4’)

* Size tolerance: length<±2mm, width<±2mm, thickness<±0.5mm< p="">

* Weight:7mm=5.5kg/sqm, 7.5mm=5.7kg/sqm, 8.0mm=5.9kg/sqm, 8.5mm=6.2kg/sqm, 9mm=6.8kg/sqm, 9.5mm=7.1kg/sqm, 12mm=9.2kg/sqm, 12.5mm=9.5kg./sqm

* Strength: >160N

* Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

* Installation: match with ceiling T-bar

Product Advantages:

1) Material: Germany Quality gypsum board,Imported high quality PVC and aluminum foil.

2) Thickness: 7mm, 7.5mm,8mm, 9mm, 9.5mm, 12mm.

3) Sizes: 595 x 595mm, 595 x 1195mm, 603 x 603mm, 603 x1212mm,2'x2,2'x4',600x600mm,600x1200mm.

4) Size tolerance: Length < 1mm, width < 1mm, thickness < 0.2mm

5) Weight: 7.6kg/sqm

6) Strength: >160N

7) Characters: Non-flammable B1, in accordance with China standard GB8624-1997

8) Installation: Match with ceiling T grid.

Main Product Features:

Standard size: 1220*2440mm 1200*600mm 603*603mm 595*595mm

thickness control: 3-30mm

Physcial property(reference only)

100% non-asbestos

Density: 0.9-1.3g/cm3

Moisture content: <=10%

Thermal conductivity:<=0.23W/MK

Asbestos content: 100% non-asbestos

Radioactivity: comply with GB6566-2001 A Class

Fire resistance: no chapping and slip cracking occur after 25times of frost-melting

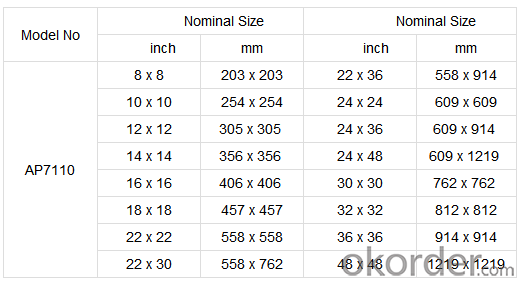

Product Specifications:

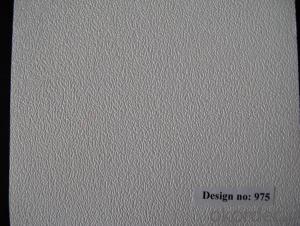

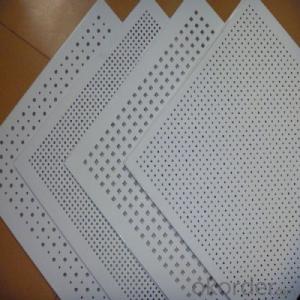

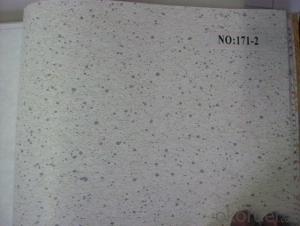

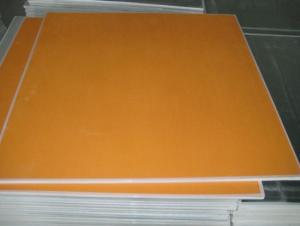

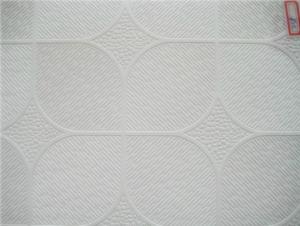

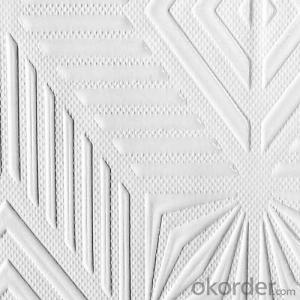

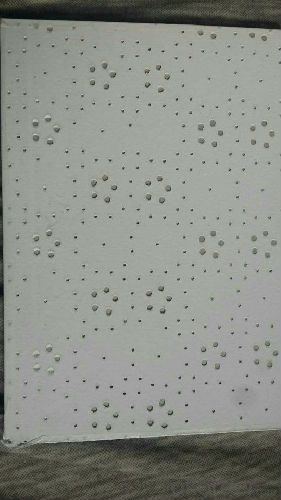

Images:

- Q:Home decoration gypsum ceiling reflective light tank is what kind of Is the separate charge reasonable?

- Each company's offer is not the same. You count down the words of a square is 155, the price is almost, a little bit expensive. Hole lamp lights are their own to buy.

- Q:The ceiling broke two big holes, how to repair

- It depends on the size of the hole if the hole is smaller than the diameter of 40mm can be used gypsum if the hole is relatively large proposal first hole the edge of the first break and then find the gypsum board repair and hole the same size fixed to the top and then look for gypsum hope to help you

- Q:Gypsum board ceiling can be installed curtains slide it? The living room has been a curtain box, so can only install the slide, after that the slide has been all closed with gypsum board, the project manager said that no problem in the wooden side. Do curtains that is not reliable, The core board Caixing. Ask how to deal with?

- Your gypsum board do not touch the water! Even the house is engaged in decoration Oh! Something you can ask me!

- Q:General gypsum board ceiling ceiling with woodworking board base?

- Direct or ceiling is directly on the bottom of the floor spray and plaster, or paste other decorative materials. Generally used for decorative requirements of residential, office buildings and other civil buildings. Direct ceiling according to the construction method and the different decoration materials. Divided into the following three; (1) direct brush (spray) pulp roof; (2) direct plastering ceiling; (3) direct paste roof. There are two ways to directly paste the ceiling: First, the decorative materials in the mold when the shop on the template, and then cast-in-place concrete, so that the decorative material directly on the concrete, demoulding can be used as a decorative surface layer, this decoration Surface use of the plate, such as dry plaster, pressure plate and so on. Second, in the concrete component installation and cast-in-place concrete demolding, clean up the base surface, with adhesive to the decorative surface layer paste. Such as gypsum board (decorative panels and slats), marble boards, laser glass and so on.

- Q:When would you like to use a single gypsum board when using double gypsum board

- With 75 keel, plus two layers of 12 thick gypsum board, just 100. Scientific name: light steel keel double gypsum any material can be, you use red brick 2 m thick wall, there will not be any technical problems. Paper

- Q:My house is being renovated, is the transformation of the old house, the original roof pressure is the wood pressure line, and now demolished, there are a lot of nails, decoration companies do not want to pull nails, like nails and then hit the gypsum pressure line cover, we Originally only intended to use gypsum in the living room pressure line and only the side of the roof is not posted, and now they want each of our rooms are posted, even the roof is also posted, would like to ask a few questions, stone ...

- Gypsum pressure line generally wide; A: generally 5-8CM; The roof is also gypsum line is not good A: There are such practices, generally not ugly; Does the nail have any good way A: horn hammer or nail and vise and so on.

- Q:The distance between the curtains of the Roman rod and the ceiling or gypsum line should be appropriate?

- The top hole is 6 cm distance, the premise is that your curtains are done to the floor

- Q:Do you have to do gypsum board on top of the ceiling?

- Yes, it is said that you can use a good glutinous rice glue to paste, a long time will not be off, but still in the ceiling to do layer gypsum board, and then then the normal batch of two putty, and then the same as the normal construction of the wall, Such as not playing gypsum board, paste is very difficult, first, the glue will be difficult to dry in the flowering,

- Q:Mineral wool board: seventy / square meter, light industry: twenty / square meter.

- Gypsum board flat top: one hundred three / square meter, light industry: twenty - five / square meter.

- Q:Ceiling installation lamp with a minimum of 10 cm, enough

- Ceiling is the roof of the living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Decoration Gypsum Ceiling Board Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords