Corrosion Resistance FRP Roofing Tile Balcony Roof Covering with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

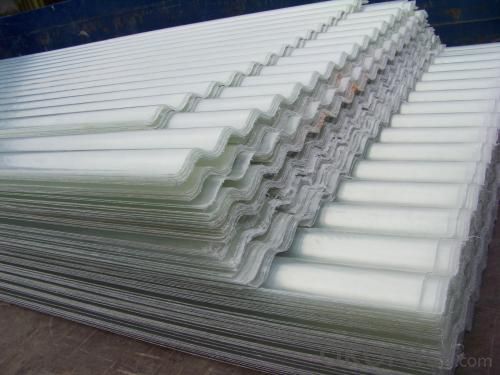

PICTURES

- Q:Can FRP roofing panels be used for greenhouses?

- Yes, FRP roofing panels can be used for greenhouses. FRP stands for Fiberglass Reinforced Plastic, and it is a versatile and durable material that has several advantages for greenhouse applications. Firstly, FRP roofing panels are lightweight yet strong, making them easy to handle and install. This is particularly beneficial for greenhouse structures as it reduces the need for heavy support structures and allows for more flexibility in design. Secondly, FRP panels have excellent light transmission properties, allowing for optimal sunlight penetration into the greenhouse. This is crucial for plant growth and ensures that the plants receive the necessary amount of sunlight for photosynthesis. Additionally, the panels can be designed to provide UV protection, preventing harmful rays from damaging the plants. Furthermore, FRP panels are resistant to corrosion, chemicals, and weathering, making them highly durable in harsh greenhouse environments. They are also resistant to mold, mildew, and pests, which can commonly occur in humid greenhouse conditions. This durability ensures a longer lifespan for the panels, reducing maintenance and replacement costs. Lastly, FRP panels are available in a variety of colors and finishes, allowing for customization to suit specific greenhouse design preferences. They can be transparent, translucent, or opaque, providing options for light control and privacy. In conclusion, FRP roofing panels are a suitable choice for greenhouses due to their lightweight nature, excellent light transmission, durability, and customization options. They contribute to creating an optimal growing environment for plants while offering long-term benefits for greenhouse owners.

- Q:Can FRP roofing panels be used for animal shelters or kennels?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for animal shelters or kennels. FRP panels are durable, weather-resistant, and easy to clean, making them suitable for such applications. They provide excellent protection against moisture, UV rays, and other environmental factors, ensuring a comfortable and safe environment for animals. Additionally, FRP panels are lightweight and easy to install, making them a practical choice for constructing animal shelters or kennels.

- Q:How do FRP roofing panels compare in cost to other roofing materials?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally considered to be a cost-effective roofing material option when compared to other traditional roofing materials. While the exact cost can vary based on factors such as the size of the roof, installation requirements, and location, FRP panels are typically more affordable than materials like metal, clay tiles, or asphalt shingles. One of the main reasons for the lower cost of FRP roofing panels is their lightweight nature, which makes them easier and cheaper to transport and install. Additionally, FRP panels offer excellent durability and longevity, requiring minimal maintenance and reducing the need for costly repairs or replacements over time. Moreover, FRP panels are known for their energy efficiency, as they provide good insulation and can help reduce heating and cooling costs, further contributing to long-term savings. It is important to note that while FRP panels are generally cheaper upfront, the overall cost may vary depending on the specific requirements of the roofing project. Factors such as the complexity of installation, additional insulation needs, or the inclusion of accessories like skylights or vents can impact the total cost. In conclusion, FRP roofing panels offer a cost-effective alternative to other roofing materials. Their lower upfront cost, combined with their durability, low maintenance, and energy efficiency, make them an attractive option for those looking for a budget-friendly and long-lasting roofing solution.

- Q:Do FRP roofing panels require special maintenance?

- Yes, FRP roofing panels require special maintenance. Regular cleaning and inspection are essential to prevent the buildup of dirt, debris, and algae on the surface. Additionally, it is important to check for any signs of damage, such as cracks or leaks, and address them promptly to ensure the longevity and performance of the panels.

- Q:Are FRP roofing panels resistant to corrosion?

- FRP roofing panels, also known as Fiber Reinforced Plastic panels, possess a remarkable resistance to corrosion. They are composed of a polymer matrix fortified with fibers, creating a composite material. This unique blend of materials grants FRP panels exceptional protection against corrosion caused by moisture, chemicals, and environmental elements. Unlike traditional metal roofing panels, which are susceptible to rust and deterioration as time goes by, FRP panels neither rust nor corrode. They are impervious to moisture, meaning they do not succumb to rust or weaken due to exposure to water or humidity. Consequently, FRP roofing panels are the perfect choice for regions with high humidity levels or coastal areas where saltwater can lead to corrosion. Moreover, FRP panels exhibit resistance to a wide array of chemicals, including acids, alkalis, and solvents. This quality renders them suitable for use in environments where chemical fumes or spills are commonplace, such as industrial facilities or agricultural buildings. Additionally, FRP panels boast excellent UV resistance, ensuring that they do not deteriorate or change color when exposed to sunlight. This makes them an enduring and long-lasting option for outdoor applications, as they will not fade or become brittle over time. In summary, the corrosion resistance of FRP roofing panels establishes them as a dependable and cost-effective choice for various applications, encompassing industrial buildings, agricultural structures, and residential roofs.

- Q:How do FRP roofing panels perform in high humidity areas?

- FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and resistance to various environmental factors. In high humidity areas, these panels perform exceptionally well due to their unique composition. The fiberglass material used in FRP roofing panels is inherently resistant to moisture, making them an ideal choice for humid environments. Unlike other roofing materials, such as wood or metal, FRP panels do not absorb moisture, preventing the growth of mold, mildew, and rot that can commonly occur in high humidity areas. Furthermore, FRP panels have a high strength-to-weight ratio, allowing them to withstand the expansion and contraction that can happen in humid conditions without warping or distorting. This stability ensures that the panels remain structurally sound and maintain their performance over time. Additionally, FRP panels are often treated with a UV-resistant gel coat, which provides an extra layer of protection against the harsh effects of sunlight. This coating helps prevent discoloration, chalking, and degradation that can be accelerated in high humidity areas. It is important to note that proper installation and maintenance are crucial for the long-term performance of FRP roofing panels in high humidity areas. Adequate ventilation and regular cleaning to remove any debris or organic matter are recommended to ensure optimal performance and prevent any potential issues. Overall, FRP roofing panels are a reliable and durable choice for high humidity areas. Their moisture resistance, stability, and UV protection make them an excellent option for maintaining the integrity and longevity of roofs in such environments.

- Q:Can FRP roofing panels be used for car washes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for car washes. FRP panels are known for their durability, resistance to corrosion, and ability to withstand harsh weather conditions. These qualities make them suitable for car washes where they may be exposed to water, chemicals, and UV radiation. Additionally, FRP panels are lightweight and easy to install, making them a practical choice for constructing roofs in car wash facilities.

- Q:Can FRP roofing panels be used in modular construction?

- Yes, FRP roofing panels can be used in modular construction. FRP, which stands for Fiber Reinforced Polymer, is a strong and durable material that is commonly used in construction due to its lightweight nature and resistance to corrosion and weathering. In modular construction, where buildings are constructed off-site in sections or modules and then transported to the final location for assembly, the use of FRP roofing panels can offer several advantages. Firstly, the lightweight nature of FRP panels makes them easier to handle and transport, contributing to the efficiency of modular construction. Additionally, FRP roofing panels provide excellent insulation properties, helping to regulate temperature and reduce energy consumption in modular buildings. This is particularly beneficial in modular construction, as maintaining energy efficiency is crucial for sustainable and cost-effective building practices. Moreover, FRP roofing panels are highly weather-resistant, with the ability to withstand extreme temperatures, UV rays, and moisture. This makes them a reliable choice for modular construction, where the durability of the building materials is important, especially during transportation and assembly. Lastly, FRP roofing panels offer design flexibility, as they can be manufactured in various colors, finishes, and profiles to match the aesthetic requirements of the modular construction project. Overall, FRP roofing panels are a suitable choice for modular construction due to their lightweight nature, insulation properties, durability, and design flexibility. Their use can enhance the efficiency, sustainability, and aesthetics of modular buildings.

- Q:Can FRP roofing panels be used for patio covers or outdoor kitchens?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for patio covers or outdoor kitchens. FRP panels are lightweight, durable, and resistant to weathering, making them a suitable choice for outdoor applications. They provide excellent protection against UV rays, rain, and hail, ensuring that your patio cover or outdoor kitchen remains well-protected from the elements. Additionally, FRP panels are easy to install and maintain, making them a convenient option for these purposes.

- Q:Can FRP roofing panels be used for walkways or catwalks?

- No, FRP roofing panels are not typically designed or recommended for use as walkways or catwalks. They are primarily used as roofing materials and may not provide the necessary strength, durability, or slip resistance required for walkway or catwalk applications. It is advisable to use materials specifically designed for these purposes to ensure safety and functionality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrosion Resistance FRP Roofing Tile Balcony Roof Covering with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords