Coolant Automotive Rubber Hose with Si20 Requirements

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:1/4"-12"

Material:Nitrile Rubber

Color:Black

Capability:Rubber Oil Hose

SAE Standard:ID From 6mm to 127mm

DIN Standard:ID From 6mm to 127mm

API Standard:ID From 51mm to 152mm

Export Markets:Global

Product Description

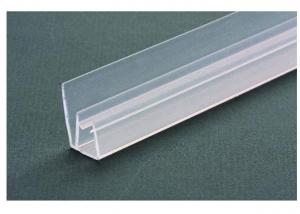

High Pressure Rubber Hose

CONSTRUCTION:

This hose consists of an inner tube of oil synthetic rubber, mutipule wire braid or spiral as reinforcements, and an oil and weather resistant synthetic rubber cover.

APPLICATIONS:

Hose range suitable to carry hydraulic fluids such as glycol, mineral oils, fuels, lubricants, emulsion, hydrocarbons etc.

1) Usage category: coolant hose ,radiator hose and supercharger, and other systems.

2) Material:EPDM

3) resistance temperature range: - -40°C~135°C -40°C~150°C -40°C~163°C

4) Working pressure : 0.3Mpa-1.5MPa

5) Standard color: black

6) ID dimension tolerance: ±0.2 - ±0.5mm

7) Wall thickness: 3.5mm~9mm

8) Polyester reinforced:1ply

This is the intercooler intake hose, which contains the material silicone and fluorine. The inner tube

uses the FKM and the outer one with the VMQ. The reinforcement is aramid.Our products are well produced and we have done such test programs:

1)Test items:Performance

2)Hardness:60±5 Shore A

3)Tensile strength:≥12Mpa

4)Elongation:≥200%

5)Burst strength:≥1.0Mpa

6)Adhesive strength:≥3.0KN/M

7)Pulse capability:The inner temperature190

- Q:How to remove the silver paint on the black rubber strip and black plastic board?

- Prepare a clean towel, then put the water that day (banana water) poured in the towel to wipe the paint touch up, be careful, don't rub the car paint (up, rubbed paint will wipe flowers) slowly rub, if only glue and glass paint fog method just do what I say, or go to the larger car repair place to see.

- Q:How long does the car seal need replacing?

- In the replacement of the entire body, should be in the overlapping part of weld is coated with a layer of sealant, adhesive layer thickness should be about 1mm, and not a virtual layer viscosity, bubbles and other defects. The elastic coating and anticorrosive coating of 3mm-4mm should be applied on the lower surface of the whole floor and front wheel housing. These measures can not only greatly enhance the sealing of the vehicle and slow down the corrosion rate of the car body, but also greatly improve ride comfort.

- Q:How to determine the service life of car tires? A new pair of tires is how to use the length of time or number of kilometers to judge?

- The traffic road is very bad, uneven or gravel pavement that the service life of the tire is a little shorter.There is an important index of tyre life, that is, the tread thickness is less than 1.6MM, you need to change.

- Q:How does the rubber wheel of the material truck effectively clean up quickly?

- Disadvantages of Ding Ji rubber: it is not recommended to use both oil, solvent, gum, kerosene and aromatic hydrogen for inner tubes, leather bags, rubber paper, window frames, rubber, steam hoses and heat resistant conveyor belts for automobile tires.

- Q:How are the car tyres made?

- The car the whole tire is not too humble, but tire for vehicles, like shoes for people, its importance is absolutely not. We understand the tire production process, help to enhance your Goodyear brand trust. Process 1: dense process, refining process is to carbon black, natural / synthetic rubber, oil, additives, accelerators and other raw materials mixed together, in the mixer for processing, the production of "glue" process. All raw materials must be tested before entering the mixer and can be used after being released. The weight of each mixer is about 250 kilograms. Each rubber component used in the tire is of a specific property. The composition of the rubber depends on the performance requirements of the tire. At the same time, the change of the composition of the rubber depends on the needs of the manufacturers and the market. These requirements mainly come from traction, driving performance, road conditions and the requirements of the tires themselves.

- Q:Could you tell me how to remove the glue mark on the door of the car?

- According to the application of the division: can be divided into warning tape, carpet tape, electrical tape, protective film, paper adhesive, winding film tape, sealing tape, module adhesive tape.

- Q:Car tires idle for four years, can you use it?

- It is recommended to see if the rubber of the tire is aging. For example, the tread pattern, the bottom of the groove, or the edge of the tire, there are countless small cracks. It is necessary to change the tire in time. No matter whether it is a new tyre or an old tire, it is not recommended to use it again.Tyres should always be stored in a cool, dry, clean, dark indoor environment. Failure to store tires according to these instructions may lead to premature aging of the tires.When the vehicle is parked, also take into account the tires to avoid the sun and rain. In the use of tires should try to avoid contact with chemicals, oil and other corrosive substances.In order to ensure safety, it is recommended to store the tires, to the regular tire shop before use, so that professional staff to look at the tires in kind.

- Q:Why use rubber for automobile tires? What is the ratio of natural rubber to synthetic rubber?

- The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. It is widely used in the manufacture of tires, hoses, tapes, cables and other rubber products.

- Q:Who knows how to maintain the rubber wheels of model cars?

- Natural rubber drawback: it is not resistant to weathering, oil is the production of adhesive tape, rubber hose, rubber material, and is suitable for the production of damping parts, brake products using oil and ethanol in the liquid with hydroxyl in the car.

- Q:How can the old tyres be recycled?

- China has been the world's largest rubber resources consumption and importing country since 2000, of which 70% of the resources for rubber tires, waste tire production in 2012 reached 280 million, the total weight of 10 million 180 thousand tons, the annual output ranked first in the world.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coolant Automotive Rubber Hose with Si20 Requirements

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords