CNC Glass Cutting Machine Cool Cutting No Heat Will Be Produced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

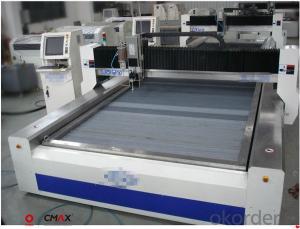

CNC Glass Cutting Machine Cool Cutting No Heat Will Be Produced

Structure of CNC Glass Waterjet Cutting Machines Description

CNC glass waterjet cutting machines is composed with CNC cutting table HP system CAD/CAM software system cutting head Hp water valve and sand controlling system. Also you can choose auto abrasive feeding system, water softening system and cooling system according to requests.

work table can be customed as to your detail request.

high presusre pump:300mpa,380mpa,420mpa

controller :servo motor driver ,Nc studio.cutting software ,run base on windows Xp.

The advantages of CNC glass waterjet cutting machines:

ü Can be transfer the drawings to cutting quickly

ü Quick position: some or few fixing quipments

ü High accuracy: reduce the recutting

ü Quicker cutting speed

ü In no need of fabrication for the working parts

ü Safer for the operator and circumstance: no steam, dust, smog, etc

ü Cool cutting: no heat will be produced

ü Clear processing: in no need of clear the working parts again

ü Good cutting finishes: in no need of rework the cutting finishes again.

ü Narrow cutting gap

ü Quick calibration and easier versatility way of cutting. It has been proved that it can be used in mass production in the ideal system

ü Fit for CAD/CAM software

ü Waterjet cutting machine can cut almost all the materials.It can cut the foilat the thickness of 200mm

Cutting Table:

| ||||||

Model(can be customed) | J-L2015 | J-L3020 | J-L4030 | J-L2060 | J-L3060 | |

| Machine type (L:bridge,X:fly arm) | Bridge | Bridge | Bridge | Bridge | Bridge | |

| Efficient cutting area(mm) | 2000*1500 | 3000*2000 | 4000*3000 | 2000*6000 | 3000*6000 | |

| Axis travel(mm) | X axis | 2000 | 3000 | 4000 | 2000 | 3000 |

| Y axis | 1500 | 2000 | 3000 | 6000 | 6000 | |

| Z axis | 150 | 150 | 150 | 150 | 150 | |

| CNC control system | Ac Servo motor | |||||

| Accuracy | Cutting accuracy | +/- 0.1mm | ||||

| Repeat accurary | +/- 0.05mm | |||||

| Processing speed | 0-15m/min | |||||

| Power supply | 240V/380V/415VAC,3ph,50Hz/60Hz(can be customed) | |||||

High Pressure System :

Intensifier Assembly

| ||||

| Parameter Model | Max.pressure(Mpa) | Max.flowrate(L/min) | Power(Kw/HP) (customized) | Intensifier parts |

| CG-3038 | 380 | 3.7 | 30/40 | whole intensifier imported from Accustream (USA) or KMT (H2O USA) |

| CG-3742 | 420 | 3.7 | 37/50 | |

CNC Controller:

Auto Abrasive Delivery System:

Auto Water Cooling Tower:

Main Parts Description

Cutting speed data:

Condition:0.25mm Ruby,0.76mm Nozzle

Materials | Thickness mm | Cutting Speed 380MPA mm/min | Cutting Speed 420MPA mm/min |

Marble | 20 | 400 | 480 |

30 | 300 | 360 | |

Granite | 20 | 320 | 384 |

30 | 200 | 240 | |

Vitrified tiles | 10 | 800 | 960 |

28 | 300 | 360 | |

Glass | 8 | 1500 | 1800 |

10 | 800 | 960 | |

18 | 500 | 600 | |

Laminated glass | 21 | 600 | 720 |

Sponge | 20 | 7000 | 8400 |

50 | 3000 | 3600 | |

80 | 2000 | 2400 | |

Carpet | 3-4 | 3000 | 3600 |

Stainless steel pane | 1 | 1200 | 1440 |

3 | 600 | 720 | |

6 | 300 | 360 | |

10 | 200 | 240 | |

16 | 100 | 120 | |

20 | 85 | 102 | |

30 | 40 | 48 | |

55 | 10 | 12 | |

65 | 5 | 6 | |

Aluminum panel | 10 | 400 | 480 |

20 | 150 | 180 | |

30 | 100 | 120 | |

70 | 40 | 48 |

The waterjet ctting machine could cut almost any materials,carbon,stainless,Brass,Aluminum,glass,marble,rubber,plastic etc.

We have many customers in more than 40 countries in the world.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:1 set.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can you accept OEM

A:YES! We can according your demand to produce.

Q10:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q:What is the instrument lathe, how to use it?

- The instrument lathe adopts spring chuck fast clamping, the motor directly drives the spindle, the size of the disc fast hand-operated operation, the vertical and horizontal positioning control turning, part of the instrument lathe is equipped with flange, tailstock device, mold clamping machine,

- Q:CNC machine tools and general machine tools in the detection of the biggest difference between the machine

- In particular, CNC machine tools are now the general batch accuracy within 0.02MM, is difficult to proportion of ordinary machine!

- Q:What are the types of machine tools?

- Machinable range is very wide, rotary body, spiral body, plane, groove, gear and so on.

- Q:CNC lathe price

- Mainly to see what you can live.

- Q:What is the main work of CNC machine tools?

- high flexibility. Processing objects change, generally only need to change the NC program, reflecting the good adaptability, can greatly save production preparation time. In the CNC machine tools, based on the composition can be more flexible automated manufacturing system-FMS.

- Q:Why is the CNC lathe so precise, what is it?

- Machine tool itself to improve the accuracy, such as precision tool holder, there is the CNC lathe drive screw and ordinary lathe drive screw is completely different, CNC lathe drive screw is used precision ball screw, motion gap and backlash

- Q:What lathes are lathes?

- Jiangsu Branch Knight Electrical and Mechanical Equipment Co., Ltd. (formerly Suzhou Zhen Ye Electrical and Mechanical Equipment Co., Ltd.)

- Q:The basic structure and function of machine tools

- 4, tool holder, knife library; control and control system; lubrication system; cooling system.

- Q:What is 16 lathes

- In the lathe can also be used drill, reaming drill, reamer, tap, die and knurling tools such as the corresponding processing.

- Q:What is the characteristic of Taiwan's Cheong Hong machine compared to other machine tools? Compared to Shenyang Machine Tool, Gao Feng machine, Friends of Ka?

- For Taiwan's Che-hung in the 1 meter 3 or more of the Dali and Longmen advantage is that other manufacturers can not be compared.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNC Glass Cutting Machine Cool Cutting No Heat Will Be Produced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products