CMAX Output PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden case |

| Delivery Detail: | 30working days after receiving the prepayment |

PVC PS Plastic Foamed Profile Production line

This line can produce high quality low foam profiles for users.

This production line is mainly composed of extruder and SJBZ low foam profile auxiliary machine combined with advancement, reliability and practicability. This line can produce high quality low foam profiles for users.

CMAX Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker.

This line with imported ABB AC inverter control, imported RKC temperature meter etc. and features of good plasticization, high output capacity, and stable performance etc.

The hot stamping machine system combined foreign technology, by the hot stamping embossing method, transfer the

coating layer from the film to the PS foamed profile. The machine with good appearance, stable performance, accurate & easy operation.

By adjust the embossing wheel the machine can work on various of different profiles.

Working together with the main extruder and other extrusion down steam equipments, this line is popular as the latest developed producing line.

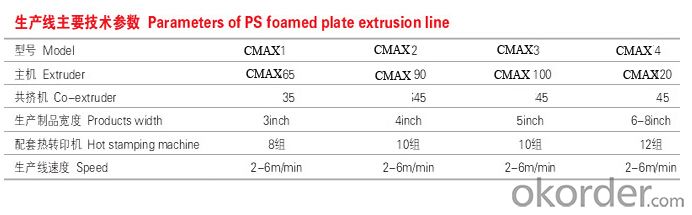

Main technical parameters:

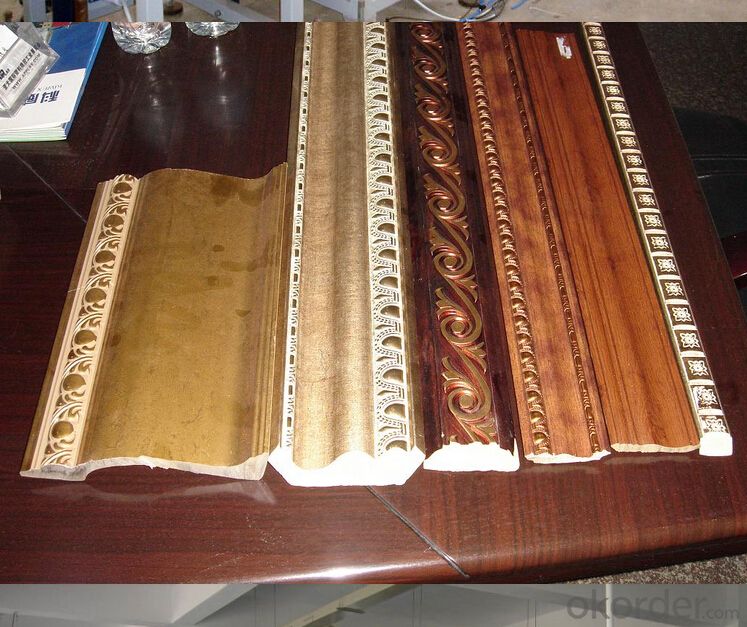

Product show:

- Q:Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

- Q:Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

- Q:What raw material does the extruder use?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die.

- Q:Is the extruder the same as the extruder?

- Extrusion machine, also called extruder, and is mainly used for power line, power cable, coaxial cable, communication cable, transmission cable, BV type civil line, electronic wire, computer wire, building line, data communication cable, RF cable, HDMI cable, cable, all kinds of high temperature silicone Teflon, core line line, network cable, optical fiber, rubber insulated wire cable wire and cable extrusion wire and cable equipment.

- Q:when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q:Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q:Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q:Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- The outer diameter is big...... I've got the tractor switched 1600 and the engine is switched 1400Chasing the answerThe extruding worker sees the line, cannot see the speed meter, the speed meter sometimes is not allowedLarge diameter, you can reduce the speed of the main engine or speed up the traction, in addition, the maximum current of the host can not exceed 2 times the power rating of the motor, more than two times will burn the motor.AskI've finished pulling the button.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Output PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products