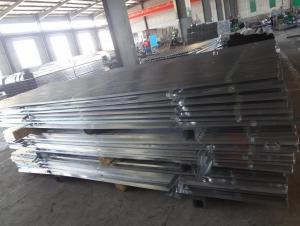

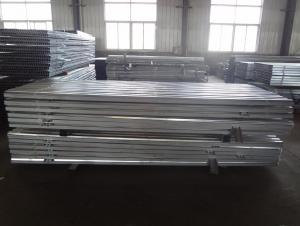

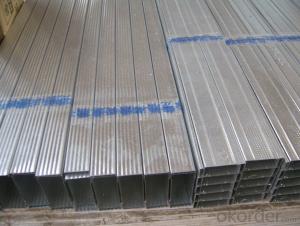

Ceiling Steel Profile 0.50mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture -proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q:The construction of the lightweight steel keel gypsum board ceiling

- Note that the material can be used to mark, such as hanging bars, expansion screws, the main keel, vice keel. Aluminum plate.

- Q:Light steel keel ceiling price is not expensive?

- Ordinary ceiling package material price below 30 yuan per square meter. / You this special requirements of high altitude operations to increase the difficulty of construction and safety risks / another keel selection and the quality and price of silicon calcium board have a certain relationship / for reference

- Q:Light steel keel paper gypsum board ceiling construction process

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed method should be tested and approved by the approved before the big Area construction.

- Q:Ceiling twenty square meters need light steel keel how many roots

- If the height of the room does not exceed 4 meters, usually: the main keel 1.2 meters, vice keel 4 meters (300MM open file), 1 meter pole, gypsum board 1.05 square (5% loss). Accessories too much here to do not introduce. The above calculation method is limited to flat top, if the shape plus 20% -30%

- Q:Light steel keel ceiling hidden information, including what ah

- Keel, hanging bars, other accessories and other quality to meet the design requirements and related norms, to have the relevant certificate and test reports, and a few copies;

- Q:Light steel keel ceiling one square meter how much money

- Ordinary flat ceiling artificial 25 yuan / m2 or so, light steel keel + gypsum board material about 25 to 28 yuan / m2 or so

- Q:Construction schedule of light steel keel ceiling

- 2 people, about 3 days. Good workers are faster

- Q:I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- Light steel keel ceiling is the use of expansion bolts to the whole wire fixed on the ceiling, that is, with five sets of the whole wire fixed up and then hang a hanging under the main keel used to fix the main keel, the main keel and vice keel lap easy to use accessories Mainly fixed, the following gypsum board is set on the keel with self-tapping, is definitely not fall off. This is a very good answer upstairs.

- Q:Light steel keel ceiling steps? How to use wood?

- You should also have a lantern with a lantern. The board is the lantern

- Q:Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The gypsum board closed should refer to the ceiling, behind the "light steel keel" is "special" indicate that the use of the ceiling required to use the "green gauze board" Keel is "light steel keel".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Steel Profile 0.50mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords