Ceiling Profile of Good Quality Ceiling Profile of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

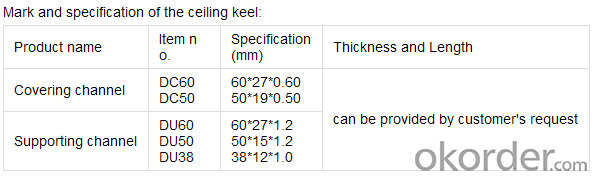

Product Specifications:

Images:

- Q:What is the keel of the aluminum veneer, or the angle welded frame?

- Aluminum veneer curtain wall using high-quality high-strength aluminum alloy sheet, its structure mainly by the panel, ribs and angle code composition. Corner can be directly from the panel bending, stamping, but also in the panel of the rivet on the corrugated angle forming. The stiffener is connected to the aluminum foil after the plate, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, ensuring the smoothness and wind resistance of long-term use. Many types of veneer, alien is the most, and some are less than keel, indoor ceiling is generally hooked board, the use of steel keel, length of 3 meters

- Q:Do steel keel ceiling, need to use white latex?

- If the ceiling with light steel keel, then white latex is used to stick gypsum board between the suture, not add putty but kraft paper Kazakhstan.

- Q:Light steel keel ceiling screw must be installed vertically? There are pictures.

- As far as possible vertical, but in the adjustment process, there are still some skewed points.

- Q:Ordinary light steel keel gypsum board ceiling budget sets which quota

- Of course, the government procurement price, and each place every year will be issued government purchase price, a dedicated book, what the price of the above things have, of course, the price above the actual price is much higher, is to do the budget The

- Q:Divided u-type light steel keel in the ceiling spacing of less than 2 meters, 2.5 meters or less, according to the large keel count spacing, or by the small keel count spacing.

- Vice keel (should be the little keel you said) and the distance between the vice keel of 30cm, gypsum board thickness of 9.5mm. If the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40cm. But in the actual construction, the vice keel spacing is 30cm, basically no one made 40cm.

- Q:Seeking: light steel keel mineral wool board ceiling, the general how much money a square? (The installation is complete)

- Different regions, different brands are not the same price, we generally installed here to complete 1 square meters 50 to 60 yuan

- Q:Light steel keel ceiling budget how to calculate

- Hanger Light steel keel material accounting A ceiling Verification according to the construction plan on the ceiling structure and size, respectively, the calculation of each indoor ceiling of the main keel and vice keel number, and then the chamber The total number of primary and secondary keels required to add the total number of M. Taking into account the size of the construction specifications and the actual size of the difference, as well as the construction of the truncation loss and other factors, the need to add the total 3% margin, so that can be practical The total number of M required is in meters (m). The empirical formula is: M total = 1.03M Note that the total number of primary and secondary keel should be calculated separately, such as the main and vice keel of the same material, you can also be calculated.

- Q:60 series light steel keel ceiling specifications

- 50,60 series is divided according to the width of the main keel.

- Q:What is the yellow water to the keel brush before making the light steel keel ceiling?

- To prevent corrosion of light steel keel rust ah.

- Q:Light steel keel ceiling steps? How to use wood?

- Steps above almost with the board may be a special shape all with light steel keel can but can be very troublesome

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Profile of Good Quality Ceiling Profile of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords