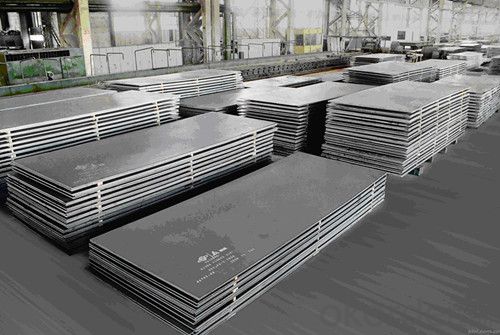

Type | Q235 carbon steel sheet prices hot rolled mild steel plate |

Standard | ASTM A36/A36M, ASTM A20/A20M, JIS G3115,DIN 17100,EN 10028 |

Material | A36,A106Gr.B,Q235,Q345,Q195,ST37-2,ST52-3,A516-Gr.55/Gr60/Gr65, Gr70,A204,A378Gr.2/Gr.12/Gr22,13CrMo44,10CrMo910,15Mo3, A515 Cr.60/Cr55/Cr65,4140,4130 etc |

Dimension | Thickness: 0.4mm-280mm as customer's requirement |

Width: 1000mm,1219mm,1250mm,1500mm,1800mm,2000mm,2200mm, 2500mm,3000mm,as customer's requirement | |

Length:2000mm,2438mm,3000mm,6000mm,as customer's requirement | |

Surface | Clean, blasting and painting according to customer requirement |

Application | It is widely used in Building Construction,Bridge,Architecture,Vehicles Components,hipping,High pressure container,Boiler,Large Structure steel etc |

5、FAQ

①How about your company?

Our company is a world class manufacturer & supplier of castings forging in carbon steel and alloy steel,which is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.The pecific time of receiving is related to the state and position of customers.

③How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.