Carbon Mild Steel Universal Beam in I Shaped Form Chinese Standard Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Mild Steel Universal Beam in I Shaped Form Description:

Carbon mild steel universal beam in I shaped form is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Carbon mild steel universal beam in I shaped form is usually made of structural steel and is used in construction and civil engineering. The carbon mild steel universal beam in I shaped form resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Carbon mild steel universal beam in I shaped form theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Carbon Mild Steel Universal Beam in I Shaped Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Carbon Mild Steel Universal Beam in I Shaped Form Images:

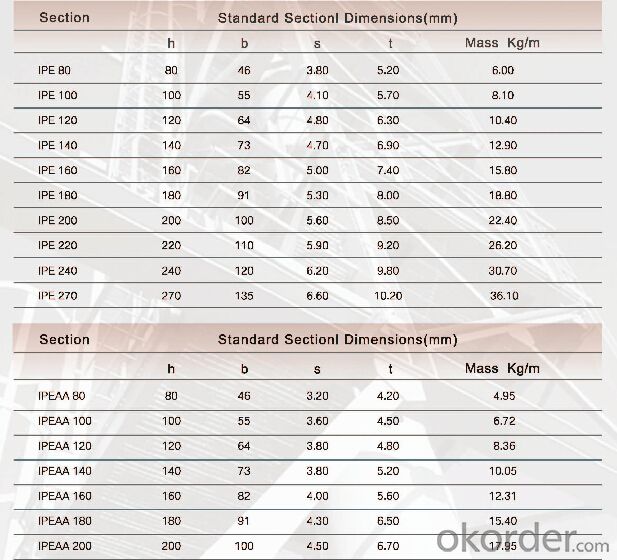

4. Carbon Mild Steel Universal Beam in I Shaped Form Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:Can steel I-beams be customized to specific project requirements?

- Yes, steel I-beams can be customized to specific project requirements. They can be fabricated and engineered to meet various dimensions, load capacities, and design specifications, ensuring they are suitable for the specific needs of a project.

- Q:How do you transport and store steel I-beams?

- Transporting and storing steel I-beams requires careful planning and adherence to safety guidelines. Here are the steps involved in transporting and storing steel I-beams: 1. Choose the appropriate mode of transportation: Steel I-beams are typically transported by flatbed trucks or trailers. Ensure that the vehicle used is capable of safely carrying the weight and size of the I-beams. 2. Secure the I-beams for transportation: Before loading the I-beams onto the vehicle, ensure that they are properly secured to prevent any movement during transit. Use sturdy straps, chains, or clamps to secure the I-beams to the flatbed, ensuring they are evenly distributed and balanced. 3. Calculate weight restrictions and adhere to regulations: Check the weight restrictions and regulations for transporting goods in your region. Ensure that the total weight of the I-beams, together with the vehicle and any additional equipment, falls within the permissible limits. 4. Arrange for specialized equipment if needed: If the I-beams are too long or heavy to be loaded or unloaded manually, you may need to arrange for specialized equipment such as cranes or forklifts. Ensure that the equipment is suitable for the weight and size of the I-beams. 5. Store I-beams in a controlled environment: If you need to store the I-beams for an extended period, it is important to protect them from environmental factors that could cause corrosion or damage. Store them in a covered, dry area to prevent exposure to rain, snow, or excessive humidity. 6. Properly stack and support the I-beams: When storing I-beams, stack them in a way that ensures stability and prevents any bending or warping. Use wooden or steel pallets to support the I-beams and distribute the weight evenly. 7. Regularly inspect and maintain stored I-beams: Periodically inspect the stored I-beams to ensure they remain in good condition. Check for any signs of corrosion, damage, or deformation. If any issues are detected, take appropriate measures to prevent further deterioration. Remember, it is crucial to follow local regulations and safety guidelines when transporting and storing steel I-beams. Consulting with professionals or experienced individuals in the steel industry can provide valuable insights and guidance for a safe and efficient process.

- Q:Can steel I-beams be customized for specific projects?

- Yes, steel I-beams can be customized for specific projects. Steel I-beams are versatile structural elements commonly used in construction due to their strength and load-bearing capabilities. They can be customized in terms of size, shape, and material specifications to suit the unique requirements of a project. Customization of steel I-beams can include altering their dimensions such as length, width, and depth to meet the specific load and span requirements of a structure. This allows engineers and architects to design structures with optimal functionality and safety. Moreover, steel I-beams can be fabricated from various types of steel, including carbon steel, stainless steel, or alloy steel, depending on the project's needs. This enables the customization of the beams to ensure compatibility with the surrounding environment, such as resistance to corrosion in coastal areas or increased strength for heavy industrial applications. Additionally, customization can involve the inclusion of specific features like holes, notches, or cut-outs in the I-beams to facilitate connections with other structural components, accommodate utility conduits, or allow for easy installation. In conclusion, steel I-beams can indeed be customized for specific projects. The ability to tailor their dimensions, material composition, and additional features allows for the creation of structurally sound and efficient designs that meet the unique requirements of any construction project.

- Q:What are the different connection methods used with steel I-beams?

- Steel I-beams can be connected using different methods depending on the application and structural needs. Examples of common connection methods include: 1. Welding: This is a widely used and efficient method for joining steel I-beams. It involves melting the ends of the I-beams together using heat, creating a strong and permanent connection. Welding can be done using various techniques like arc welding, MIG welding, or TIG welding. 2. Bolting: Another commonly used method is bolting, which involves using bolts and nuts to secure the I-beams together. This method allows for easy disassembly and reassembly if necessary. It is suitable for situations where adjustability is required or welding is not feasible. 3. Riveting: Riveting is a traditional method that involves using metal fasteners called rivets to connect the I-beams. While it provides a strong and durable connection, it is a more time-consuming and labor-intensive process compared to welding or bolting. 4. Tensioning: Tensioning utilizes high-strength bolts and nuts to clamp the ends of the I-beams together. It is commonly used when minimal deformation is desired or when a high level of adjustability is required. 5. Adhesive bonding: For specialized applications where welding or bolting is not suitable or a seamless and aesthetically pleasing connection is desired, adhesive bonding can be used. This method involves using high-strength epoxy or adhesive to bond the I-beams together. It is important to consider factors like load requirements, structural design, cost, and construction time when choosing a connection method. Consulting a structural engineer or construction professional is recommended to determine the most appropriate method for a specific project.

- Q:How do steel I-beams contribute to the overall stability of a building?

- Steel I-beams contribute to the overall stability of a building by providing structural support and load-bearing capabilities. Due to their shape and composition, I-beams are able to distribute weight evenly across their length, allowing them to bear heavy loads. They are commonly used in the construction of buildings because of their high strength-to-weight ratio, which makes them capable of withstanding significant forces and minimizing the risk of structural failure. Additionally, I-beams can be connected together to form a framework, creating a rigid and stable structure that can withstand various external forces such as wind, earthquakes, and heavy loads.

- Q:Are steel I-beams resistant to magnetic fields?

- Typically, magnetic fields don't have a high resistance against steel I-beams. Steel, being a ferromagnetic substance, possesses the ability to be magnetized to some degree. Nevertheless, steel's magnetism is relatively feeble in comparison to other ferromagnetic materials such as iron or nickel. Consequently, magnetic fields can exert an influence on steel I-beams, but the impact is generally negligible. Generally, the magnetic field would need to possess considerable strength to substantially affect the steel I-beams.

- Q:How do steel I-beams perform in areas with heavy snow loads?

- Steel I-beams are known for their strength and durability, making them an ideal choice for areas with heavy snow loads. The unique design of I-beams, with their flanges and web, allows them to evenly distribute the weight and pressure exerted by the heavy snow, preventing structural failure. The flanges of the I-beams provide resistance against bending and twisting forces, while the web acts as a support system, ensuring the beam remains stable and can bear the weight of the snow. This combination of strength and support enables I-beams to effectively withstand heavy snow loads without significant distortion or damage. In areas with heavy snow loads, building codes often require the use of steel I-beams to ensure the structural integrity of buildings. This is because I-beams have been proven to withstand the excessive weight and are less prone to deformation or collapse compared to other construction materials. Additionally, steel I-beams have high tensile strength, meaning they can resist the forces of compression and tension caused by snow accumulation and melting. This further enhances their performance in areas with heavy snow loads. It is important to note that while steel I-beams are highly effective in handling heavy snow loads, proper engineering and design are crucial for their successful implementation. Factors such as the size and spacing of the I-beams, as well as the overall structural design, must be carefully considered to ensure the building can safely support the snow loads over an extended period. Overall, steel I-beams are an excellent choice for areas with heavy snow loads due to their strength, durability, and ability to evenly distribute weight. Their performance in such conditions has been widely recognized, making them a popular choice for construction projects in snow-prone regions.

- Q:Can steel I-beams be used in retail or commercial buildings?

- Yes, steel I-beams can be used in retail or commercial buildings. Steel I-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support and can withstand heavy loads and stresses, making them suitable for large retail or commercial buildings. Steel I-beams also allow for open and flexible floor plans, enabling the creation of spacious and customizable retail or commercial spaces. Additionally, steel I-beams are fire-resistant and have a high resistance to pests, which makes them a reliable choice for commercial structures. Overall, steel I-beams are a popular choice for retail or commercial buildings due to their structural integrity, design flexibility, and long-term cost-effectiveness.

- Q:Are steel I-beams suitable for long-span bridges?

- Yes, steel I-beams are suitable for long-span bridges. Steel I-beams are widely used in bridge construction due to their high strength-to-weight ratio and ability to support heavy loads over long distances. They are capable of spanning large distances while maintaining structural integrity and stability. Additionally, steel I-beams have excellent durability and resistance to environmental factors such as corrosion, making them suitable for long-span bridges that may be exposed to harsh weather conditions. The flexibility of steel also allows for the creation of various bridge designs, including suspension bridges and cable-stayed bridges, which can span even longer distances. Overall, steel I-beams are a reliable and commonly used choice for constructing long-span bridges.

- Q:What are the different types of steel reinforcements for I-beams?

- I-beams can be reinforced using various types of steel, each possessing unique characteristics and advantages. Hot-rolled steel, for instance, is a commonly used reinforcement. To manufacture this type of reinforcement, the steel billet or ingot is heated to high temperatures and then rolled into the desired shape. Known for their exceptional strength and durability, hot-rolled steel reinforcements are ideal for heavy-duty applications like constructing bridges and high-rise buildings. Another popular option for reinforcing I-beams is cold-formed steel. This type of reinforcement is created by bending or shaping cold steel sheets or strips into the desired form. Cold-formed steel reinforcements are frequently utilized in light structural applications, such as residential construction, due to their cost-effectiveness and ease of fabrication. Apart from hot-rolled and cold-formed steel reinforcements, there are also specialized types available. For instance, stainless steel reinforcements are often employed in environments where corrosion resistance is crucial, such as coastal areas or chemical plants. Additionally, carbon steel reinforcements are widely used in numerous applications due to their affordability and high strength. It is important to note that the choice of steel reinforcement for I-beams depends on several factors, including structural requirements, load-bearing capacity, and environmental conditions. Engineers and architects carefully consider these factors when selecting the appropriate type of steel reinforcement to ensure the safety and longevity of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Mild Steel Universal Beam in I Shaped Form Chinese Standard Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords