Butterfly Valve Made in China on Hot Sale with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

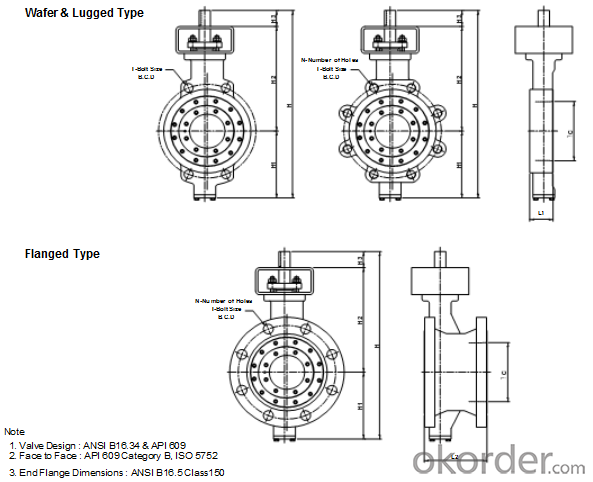

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:I'm going to put a solar energy and an electric water heater installed in the same hot water pipe, a valve, a valve open and close the valve B and vice versa the installation of solar and electric water heater, there can be no linkage valve?

- Yes, three ball valves (T and L) are two. Switch more complex point of the valve is basically ball valve, such as central air-conditioning commonly used to the four - way reversing valve.

- Q:Which direction is the valve? Which direction is it?

- And we usually drink mineral water, drink bottles are in the same order

- Q:Which brand of electric valve is good?

- The electric actuator imports now commonly used with Omar, Rotok, SIEMENS, you should still work to decide which Denso, such as regulating type? Switch mode? Intelligent? Regular type? There are valves can choose some well-known brands

- Q:I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- I was about 08 years of contact valve, indeed many, but a company, all products will not have, are designed to do certain types of valves, such as for HVAC, or petrochemical, some other valves used in engineering, will do the purchase, so you only according to the company's products study on the line, need to learn what, what, high efficiency.If you do the design, you have to learn a lot of things: "mechanical design manual" and "valve design manual" is essential, often used;Of course, functional things are the basis, that is, the structure, the work principle must be obtained first, in order to do relevant design and improvement;First of all, the structure design, CAD must learn, three-dimensional software also have to learn one, Solidworks, Peo/E, UG, Catia can be;Second, strength analysis is necessary, so in mathematics, mechanics, mechanical design things to learn solid; can make strength analysis with finite element analysis software, need to learn, software Comosworks, Ansys;Third, the valve design will have fluid aspects, flow design, flow capacity, flow characteristics of the study, to study fluid mechanics, heat transfer, etc., CFD software has Fluent, Ansys, CFX, Star-CD;In addition, materials and technical aspects should be learned.Slowly, I also step by step by side with coming.Hope to be of help to you.

- Q:What is the diameter of a general pipe valve?

- In fact, the essence of the problem is the corresponding relationship between the nominal diameter and other dimensioning methods. Valves are generally marked with nominal diameter (DN***), such as DN150, DN100 and so on. There are many kinds of marking methods for pipes, such as outer diameter, inch inch, nominal diameter, etc.. Only when the other dimensioning is converted to nominal diameter, the valve and the pipe correspond to each other.

- Q:The low pressure in our factory is below 1.6Mpa, medium pressure is 2.5-6.4MPa, high pressure is 10-80MPa.Where's qusetion:1.6-2.5Mpa??? Which section does it belong to?. I think many of them are defined on the Internet But I didn't say, where's 6.4-10Mpa?

- Low high is just a general statement, such as the height, there is no clear distinction between what theNow the pressure piping fittings design is specific to the pressure value, not to say that the place to install a medium pressure valve.The pressure piping is generally classified according to the pressure, and the valve can be distinguished by this.Of course, you say 2 of the medium pressure valve is also OK, belong to the low-pressure valve, no one was investigatedBy pressure:1 、 low pressure pipeline engineering pressure less than 1.6MPa;2 、 medium pressure pipeline engineering pressure 1.6-6.4MPa;3 、 high pressure pipeline engineering pressure 6.4-10MPa;4 、 super high pressure pipeline engineering pressure 10-20MPa.

- Q:What does valve 41F-40C mean?

- Incomplete model4 is the flange1 is the formF is seat material, fluoroplastic, ptfe,40 nominal pressure 40 kgC body material carbon steelFront also have to add valve category code, such as manual ball valve, Q41F-40C manual code is 0, but this 0 we don't write out, so only written Q41F-40C electric ball valve, Q941F-40C 9 represents electricGate valve is Z41F-40C

- Q:What are the general types of valves?

- Pneumatic and hydraulic valvesPneumatic valve and hydraulic pressure based on a certain air, water or oil as the power source, using the cylinder (or cylinder) and the movement of the piston to drive the valve, the general pneumatic air pressure is less than 0.8MPa, the hydraulic or hydraulic pressure is 2.5MPa~25MPa. Such as used to drive diaphragm valves; rotary gas and liquid drives are used to drive ball valves, butterfly valves, or plug valves. The driving force of the hydraulic device is large, and it is suitable for driving large diameter valves. If used for driving plug valves, ball valves and butterfly valves, the reciprocating motion of the piston must be turned into a rotary motion. In addition to the cylinder or hydraulic cylinder piston to drive, but also the use of pneumatic film driven, because of its small stroke and driving force, it is mainly used for regulating valves.Manual valveThe manual valve is the most basic way of driving the valve. The utility model comprises a hand wheel, a handle or a plate hand, and is driven directly and driven by a transmission mechanism two kinds. When the starting torque of the valve is large, it can be driven by gear or worm gear to achieve the purpose of omitting. Gear drive, spur gear drive and bevel gear drive. Gear reduction ratio is small, suitable for gate valve and stop valve, worm gear drive is relatively slow, suitable for cock flashing, ball valve and butterfly valve

- Q:What does the valve "4" mean?

- An inch of eight points, home tap, valve is generally 4 points

- Q:Valve legend

- F means the initial letter of the valve, which is shown as a stop valve

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve Made in China on Hot Sale with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords