ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

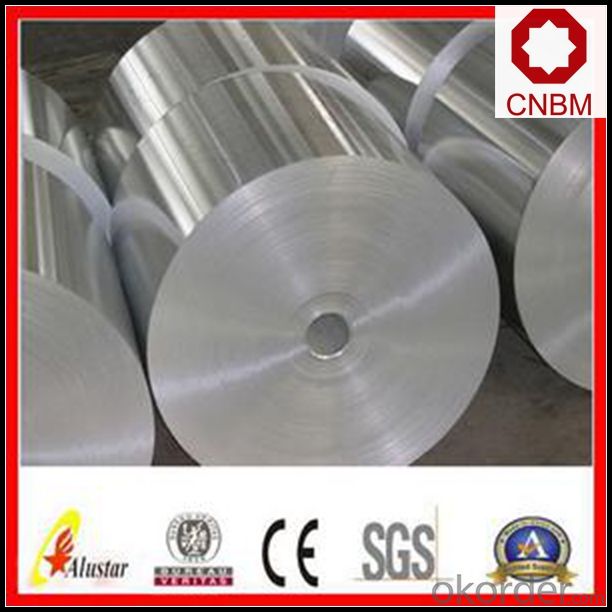

5. Image of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

6. Package and shipping of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in solar panel applications?

- Indeed, solar panel applications can make use of aluminum coils. Aluminum, a lightweight and robust substance, finds widespread use across diverse industries, including the solar panel industry. The base material for solar panels often consists of aluminum coils owing to their corrosion resistance, exceptional thermal conductivity, and excellent electrical conductivity. These attributes render aluminum coils ideal for efficiently transmitting heat and electricity within solar panels, thereby guaranteeing optimal performance and efficiency. Additionally, aluminum stands as a highly sustainable material, as it can be readily recycled, making it an environmentally conscious option for solar panel applications.

- Q:What are the common testing methods for aluminum coils?

- Some common testing methods for aluminum coils include visual inspection, dimensional measurements, hardness testing, corrosion resistance testing, tensile strength testing, and conductivity testing. These methods help ensure the quality and performance of aluminum coils in various applications.

- Q:How do aluminum coils contribute to the energy efficiency of products?

- Aluminum coils contribute to the energy efficiency of products by providing excellent heat transfer properties. Their high thermal conductivity allows for efficient heat exchange, helping to cool or heat products more quickly and effectively. Additionally, aluminum coils are lightweight, which reduces the energy required for transportation and installation. The durability and corrosion resistance of aluminum also contribute to the longevity of products, reducing the need for frequent repairs or replacements, further enhancing energy efficiency.

- Q:What is the typical coefficient of friction for aluminum coils?

- The typical coefficient of friction for aluminum coils can vary depending on various factors such as the surface conditions, lubrication, and the specific type of aluminum alloy used. However, in general, the coefficient of friction for aluminum coils is relatively low compared to other materials. It typically falls within the range of 0.1 to 0.4.

- Q:What are the thickness tolerances for aluminum coils?

- The thickness tolerances for aluminum coils can vary depending on the specific grade and alloy of aluminum being used. Generally, the tolerance range for aluminum coil thickness is within +/- 0.003 to 0.015 inches (0.076 to 0.381 mm). However, it is important to note that different industries and applications may have their own specific requirements and tolerances. It is recommended to consult the relevant industry standards or specifications to determine the precise thickness tolerances needed for a particular application.

- Q:Are aluminum coils suitable for food packaging?

- Yes, aluminum coils are suitable for food packaging. Aluminum is a safe and widely used material for packaging food due to its excellent barrier properties, resistance to corrosion, and ability to maintain the freshness and quality of the packaged food products.

- Q:What are the common recycling methods for aluminum coils?

- The common recycling methods for aluminum coils include sorting them based on their alloy composition, melting them down to remove any impurities, and then reusing the molten aluminum to make new coils or other aluminum products.

- Q:Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a relatively high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). This makes it suitable for applications that involve high-temperature environments. Additionally, aluminum has excellent thermal conductivity, which allows it to dissipate heat efficiently. This property makes aluminum coils commonly used in heat exchangers and various heating applications. However, it is important to note that the specific temperature limit for aluminum coils may vary depending on the specific alloy and application.

- Q:What is the minimum thickness available for aluminum coils?

- The specific requirements of the application can cause variations in the minimum thickness available for aluminum coils. Typically, aluminum coils can have a minimum thickness of approximately 0.006 inches or 0.15 millimeters. It is crucial to consider that different industries or uses may impose distinct minimum thickness demands. Therefore, it is advisable to seek guidance from a manufacturer or supplier to ascertain the suitable thickness for a particular application.

- Q:What are the advantages of using aluminum coils over other materials?

- There are numerous benefits to utilizing aluminum coils as opposed to alternative materials. To begin with, aluminum boasts a lightweight composition, thereby facilitating simpler handling and transportation. This characteristic also renders it more cost-effective, as it necessitates less energy for manufacturing and installation. Furthermore, aluminum exhibits a remarkable resistance to corrosion. It remains unaffected by rust, even when subjected to harsh environmental conditions, rendering it highly suitable for outdoor applications. The resulting durability ensures an extended lifespan and diminishes maintenance expenses in the long term. Moreover, aluminum coils excel in terms of heat transfer properties. Possessing a high thermal conductivity, they facilitate efficient heat exchange. This renders them ideal for crucial applications such as heating, ventilation, and air conditioning systems. In addition, aluminum serves as an eminently recyclable material. It can undergo multiple recycling processes without compromising its quality or performance. This not only curtails waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer tremendous versatility in terms of design and customization. They can be effortlessly molded, shaped, and coated to meet specific requirements. This flexibility permits a wide array of applications across diverse industries, including automotive, construction, electronics, and aerospace. In conclusion, the array of advantages associated with aluminum coils, encompassing their lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, establishes them as the favored choice over alternative materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords