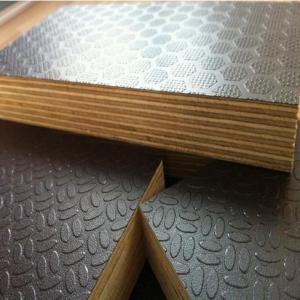

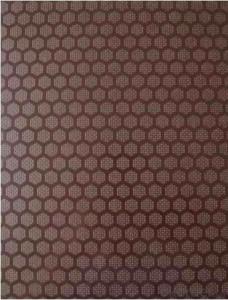

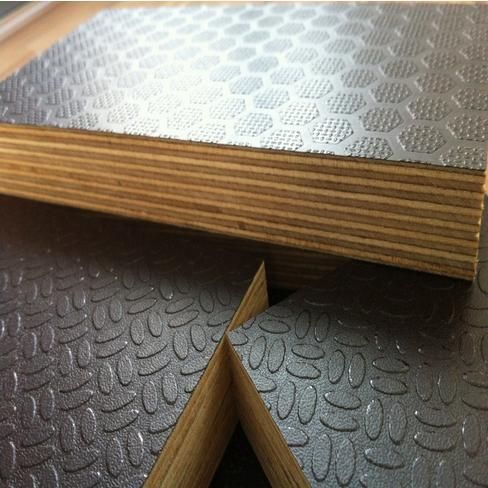

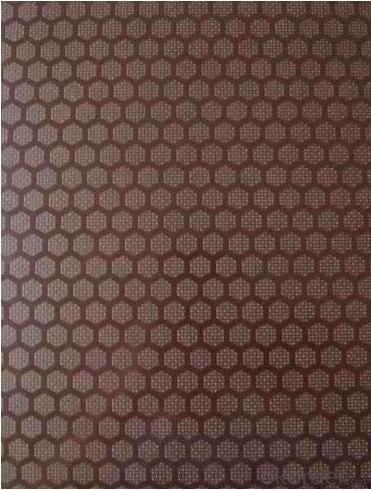

Anti-Slippery Film Faced Plywood Brown Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 10000 M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description:

Anti-Slippery Film Faced Plywood are widely used in construction repeatly and sometimes for stage boards..

Characters:

Anti-Slipping, Different styles/Designs, Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

Product name:Anti-Slippery Film Faced Plywood

Size:1220x2440mm,1250x2500mm

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar,Eucalyptus,hardwood,combi

Film:brown with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

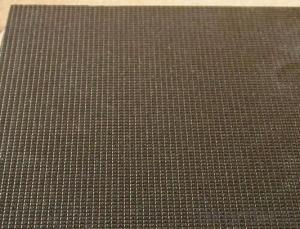

General Information of Combi Core Black Film Faced Plywood

1.Size(mm): 1220x2440; 1250x2500 Thickness(mm):18; 15; 12; 20; 21

2.Glue: MR, melamine, phenolic, WBP Core: combi

3.Film Color: black

4.Application :Construction material used for concrete forming mouldings.

5.Standard ISO9001

FAQ:

Q1.How many times it can be used?

A1: It mainly depends on hotpress times, quality of raw materials and type of Glue. Normally, Melamine glue poplar core two times hot press film faced plywood can be used about 5-8times.

- Q:defects are divided into four grades

- It is generally judged by visualizing the allowable defects on the plywood. The grade depends on the permissible material defects, machining defects, and the requirements for splicing

- Q:What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q:Contemporary plywood market development

- as well as foreign high-quality hardwood wood constantly added for the Chinese plywood industry's continuous development To provide a wealth of raw materials; adequate human resources,

- Q:Class I resistant weather plywood Class II water resistant plywood

- Medium density fiberboard: density fiberboard is a kind of man-made sheet, it is the plant fiber as raw material, the chipping, fiber separation

- Q:Selection of plywood in plywood production

- In the production of plywood, derived from a lot of color varieties, one of the most important one is in the original plywood board surface affixed with a thin layer of decorative veneer, known as decorative veneer veneer plywood, the market referred to as decoration Board or trim panel.

- Q:Plywood in the material defects?

- resin leakage (resin) resin streak trees after the local injury, the resin gathered in a large number of them and through the surrounding wood and the formation of color than the surrounding normal wood deep

- Q:The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q:The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q:What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

- Q:The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-Slippery Film Faced Plywood Brown Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m³

- Supply Capability:

- 10000 M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords