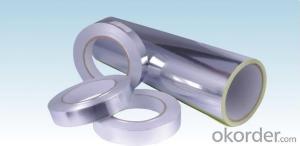

Aluminum Foil Tape HVAC Insulation Tape and Flexible Duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

3)Excellent Peel Adhesion

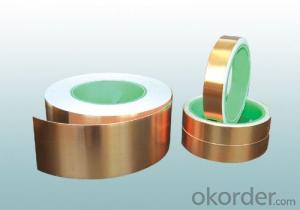

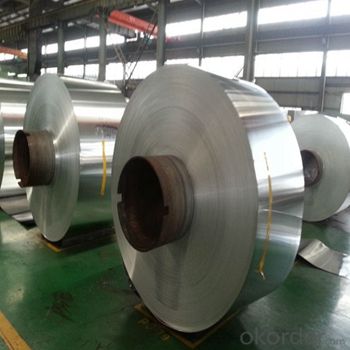

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

5.FAQ

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q:If heat can be transferred to a sample of aluminum at a rate of 0.260 J/s (assuming no loss of heat to the surroundings), how long will it take to raise the temperature of 64.8 g of the aluminum by 63.0 oC ?

- belle clara daisy kate rose

- Q:Bureau of Labor Statistics data correlated against party majority/minority numbers in D.Cshows that adding Democrats significantly tends to yield reduced demand for: Fruit and vegetable canning, Wired telecommunications carriers, Plastics material and resins manufacturing, Aircraft engine engine parts mfg, Aircraft part auxiliary equipment mfg, Farm machinery equipment mfg, Corrugated solid fiber box mfg, Turbine turbine generator set unit mfg, Hardware mfg, Automobile and light duty motor vehicle mfg, Aluminum sheet, plate foil mfg, Sheet metal work mfg, Line-haul railroads, Paint coating mfg, Pharmaceutical preparation mfg, Iron steel mills, Sawmills, Ball and roller bearings, Construction machinery mfg, Electronic capacitor mfg, Switchgear switchboard apparatus mfg, Machine tool mfg, Oil gas field machinery equipment mfg etc.

- I believe itThe Democratic Party wouldnt be anywhere without a steady supply of poor peopleThat is why the Dems have no incentive to help the poor better their livesTheir voter base would vanish.

- Q:i need a recipe for baked mozzarella sticks please.

- the best straightener is the maxi glideyou can buy it bed bath and beyondit has steam burst technology so that helps with humidity issuesalso, i would recommend garnier anti humidity productsif your hair is thick, then use tcb greasedon't straighten it every day because too much heat is not good for hairfor it to be super straight, there's this spanish stuff called sepalthe one for super straight hair is greatuse all of this like 3 times a week, but you probably won't even need it that much.

- Q:Im using this aluminum powder to make thermiteI need it super fineBut when i use a super fine sandpaper it just sticks to the sandpaperWhen i use a coarse grit its to big of a mesh and the thermite wont light wellI have a belt sander also but when i took off the bag and put a ziplock bag over it and sanded something nothing came into the bag?

- The other recipes gave you the cheesy sauce that's mixed with the pastaI make mine in layers, with a white sauce (made from a roux) over the topI make a small package of macaroni elbow pastaMeanwhile, make a roux with about 1 stick of butter and 2 TBof flour; whisking with a wire whiskThen, gradually add 2 to 2-1/2 cof milk to it and keep whisking until it's thickenedI add salt, pepper, Tony Chachere's Creole SeasoningFinely chop about 1/2 onion, and 1/2 each red green bell pepper, and some fresh cilantro, basil oregano, or parsleyLayer a greased casserole dish with 2-3 layers of the following (this order): cooked pasta; veggies; grated cheese (I like mozzarella or provolone, but you could use cheddar or American)On top of the top layer, pour the white sauce over it all and smooth over the topDot with butter (you could also sprinkle some cornflake crumbs or bread crumbs on top)Bake at 375 for about 35-45 min, or until it bubbles

- Q:I've got some samples made of aluminium alloy (HE30 BS1476)They've been solution treated at 520°C for 90 minutesWhat difference in hardness (from just after the treating) can I expect to get in one week, leaving the sample at room temperature and WHY?

- Your best bet is to take a sample and send it to a labSend an original piece before solution treating then another after treating and another after one weekThe values of hardness have a range depending on the treatment process and the age of the materialSomeone might be able to ballpark a value but you won't really know what it is until you've had it tested.

- Q:Surely they must stand up.

- The P1 is a very good gunThey stand up just fineThe one thing to remember about the P38 action is all the forces are in the slideThe only thing that the frame does is provide a method to contain the magazine, the action parts and provide a bearing surface for the slide to moveThe slide moves on large surfaces, wear is a minor issueThe only consideration is the amount of shooting that you plan to doIf you are like most people, you will shoot no more than a thousand rounds per year through this gunYou might see some wear problems after twenty or thirty years.

- Q:I am looking for an Simple Paper Mache (Small) Doll RecipeI Don't Want To Use NewspapersWhite Strips (?

- I love club penguinCan't liePlay tetris or just search free games.

- Q:do I defrost it for three days in the refreghow long do I cook it

- Ground chuck IS ground beef.ground from a specific part of the animal, the front shoulder.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Tape HVAC Insulation Tape and Flexible Duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords