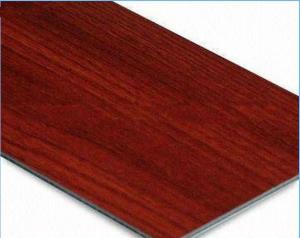

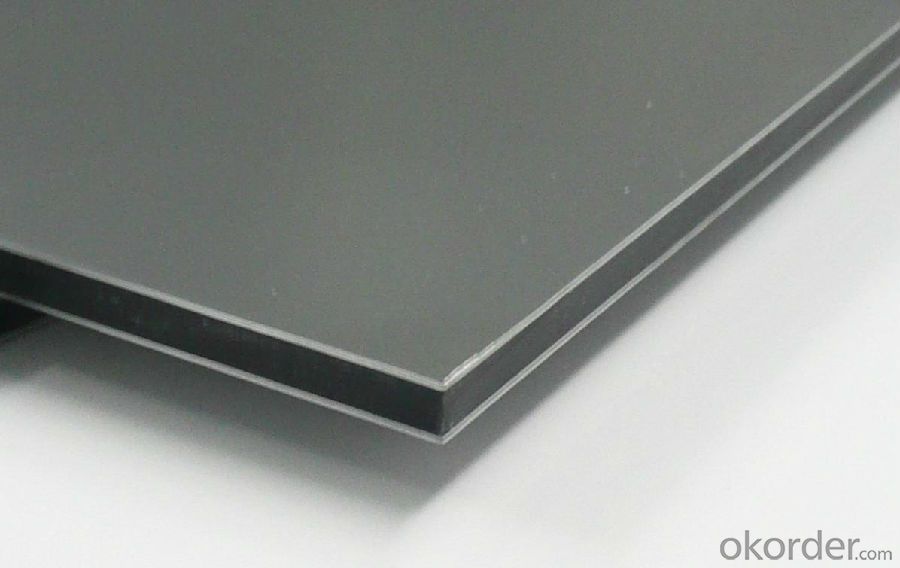

aluminum composite panel 5mm interior aluminum cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

aluminum composite panel 5mm interior aluminum cladding

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q:Are aluminum-plastic plates harmful to the human body? Can the kitchen bathroom ceiling be used? Durable? Afraid of the sun?

- Aluminum-plastic plate, also known as: aluminum-plastic composite board. Is the chemical treatment of coated aluminum as the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

- Q:How to judge the market now on the advantages and disadvantages of aluminum-plastic composite panels

- Whether it can easily tear the aluminum down, inside the board can not point

- Q:Where is the sale of aluminum-plastic color steel composite panels (panel is 0.5mm thick blue steel plate is a foam or rock wool floor is aluminum-plastic plate)

- There is no problem for the material, you can provide samples, require manufacturers to contact the manufacturer of the material, there are problems can also go to "Caigang Machinery Technology Forum" to ask questions to see the other manufacturers in the industry produced no

- Q:What is aluminum plastic plate?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q:What is the use of aluminum-plastic plate

- It can be used for building facades, curtain wall panels, renovation of old buildings renovation, interior walls and ceiling decoration, advertising signs, display stand, clean dust works. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials.

- Q:China where auspicious aluminum-plastic plate manufacturers? I have a lot of aluminum plastic panels.

- In China's words there is no auspicious aluminum-plastic plate manufacturers

- Q:Aluminum veneer and aluminum sheathed which fire?

- No fire under the fire!

- Q:2000 watts of laser can cut 2.5mm aluminum-plastic plate (double-sided aluminum), cutting will be reflective of laser damage

- Can not, below a layer of plastic, do not wear

- Q:Aluminum plate how much money

- One side difference of about 50

- Q:Aluminum-plastic composite panels and insulation materials have some requirements, such as the layout to 1150mmx2200mm can be reinforced, reinforced strength can meet the requirements?

- Layout is too large, poor control in the construction, the construction technology, base flatness are challenges!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminum composite panel 5mm interior aluminum cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords