Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

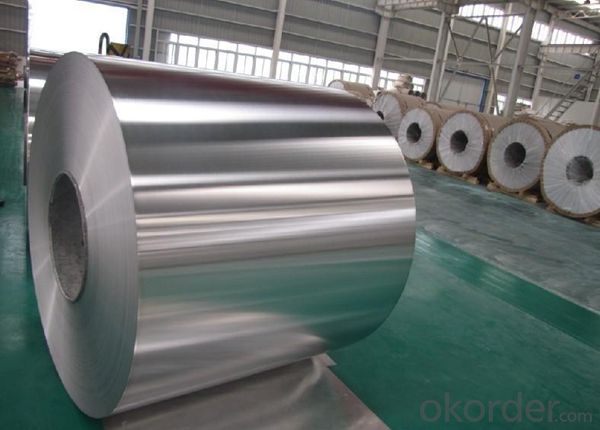

3. Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:What is the typical thickness of an aluminum coil?

- The typical thickness of an aluminum coil can vary depending on its intended use and application. However, common thicknesses range from 0.15mm to 8mm.

- Q:How do aluminum coils contribute to lightweight vehicle design?

- Due to their unique properties and manufacturing processes, aluminum coils play a crucial role in the attainment of lightweight vehicle designs. Aluminum, being a lightweight material itself and weighing only about one-third of steel, is an ideal choice for lightweight vehicle design. When aluminum is formed into coils, it offers various advantages that contribute to the overall reduction in vehicle weight. First and foremost, aluminum coils possess high formability, enabling the creation of complex shapes using less material. This characteristic allows automakers to design intricate body panels and structural components that are both lightweight and possess improved aerodynamics and fuel efficiency. The ability to shape aluminum coils intricately also provides increased flexibility in design, leading to more innovative and visually appealing vehicle designs. Secondly, aluminum coils exhibit an exceptional strength-to-weight ratio, making them an excellent option for structural components. Despite their lightweight nature, aluminum coils provide exceptional structural integrity, ensuring the safety and durability of the vehicle. By incorporating aluminum coils into the chassis, suspension systems, and other critical components, automakers can reduce weight while maintaining the necessary strength and rigidity required for safe operation. Moreover, aluminum coils possess excellent corrosion resistance, which is vital for the long-term longevity of the vehicle. Corrosion can significantly impact the structural integrity and overall performance of a vehicle. By utilizing aluminum coils, automakers can minimize the risk of corrosion-related issues, resulting in a longer lifespan for the vehicle and reduced maintenance costs. Lastly, the utilization of aluminum coils aids in the overall reduction of vehicle weight, leading to improved fuel efficiency and decreased greenhouse gas emissions. Lighter vehicles require less energy for acceleration and to maintain speed, resulting in enhanced fuel economy. This benefit becomes increasingly significant as the automotive industry strives to develop more sustainable and eco-friendly vehicles. In conclusion, aluminum coils make a significant contribution to the design of lightweight vehicles by offering high formability, exceptional strength-to-weight ratio, corrosion resistance, and overall weight reduction. These properties enable automakers to design vehicles that are not only lighter but also safer, more fuel-efficient, and visually appealing. As the demand for lightweight vehicles continues to rise, aluminum coils play a vital role in achieving these design objectives.

- Q:Are there any restrictions on the coil length of aluminum coils?

- Yes, there are restrictions on the coil length of aluminum coils. The maximum coil length is typically determined by the capabilities of the equipment used for coil production and handling. Factors such as the size and capacity of coil winding machines, transportation and storage limitations, and the weight and stability of the coil itself all play a role in determining the maximum coil length. Additionally, longer coils may be more prone to handling and logistical issues, such as increased risk of damage during transportation or difficulties in uncoiling and processing. Therefore, it is important to consider these restrictions and limitations when determining the appropriate coil length for aluminum coils.

- Q:What are some normal everyday products made from aluminum that I can use to recycle?

- cool drink cans.

- Q:How are aluminum coils used in the packaging industry?

- The packaging industry relies heavily on aluminum coils due to their exceptional properties and versatility. These coils are extensively employed in the creation of diverse packaging materials. A primary use of aluminum coils in the packaging industry is the production of aluminum foil. This thin sheet of aluminum is utilized for numerous packaging applications. Its flexibility, light weight, and outstanding barrier properties make it perfect for preserving the freshness, taste, and quality of food products. Aluminum foil is commonly employed for wrapping food items like sandwiches, snacks, and leftovers. It is also used to package pharmaceutical products, cosmetics, and other consumer goods. Additionally, aluminum coils are employed to manufacture aluminum cans, which are widely used to package beverages such as soda, beer, and energy drinks. Aluminum cans are lightweight, durable, and offer excellent protection against light, oxygen, and moisture. They also have a longer shelf life compared to other packaging materials, ensuring the preservation of taste and quality. Furthermore, aluminum coils are employed in the production of blister packs, which find common use in the pharmaceutical industry. Blister packs consist of a plastic sheet with individual compartments for medications or capsules. The aluminum coil is laminated onto the plastic sheet, providing a barrier against light, moisture, and oxygen, ensuring the stability and integrity of medications. Moreover, aluminum coils are utilized in the production of flexible packaging materials such as pouches, sachets, and bags. These packaging materials are widely used for various products, including snacks, pet food, coffee, and personal care items. Aluminum coils are laminated onto plastic films to create a barrier against moisture, oxygen, and light, thus extending the shelf life of the packaged products. In conclusion, aluminum coils are essential in the packaging industry, offering numerous benefits such as light weight, durability, barrier properties, and versatility. From aluminum foil to cans, blister packs to flexible packaging materials, these coils are crucial for preserving the freshness, taste, and quality of various products.

- Q:Why does the end face of aluminum coil have grease spots?

- The reason may be that the manufacturer hasn’t cleaned. Before being coated, the aluminum should be cleaned carefully. Otherwise the paint will peel off.

- Q:Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a commonly used material due to its lightweight, conductivity, and corrosion resistance properties. It is often used in electronic devices such as capacitors, inductors, and transformers.

- Q:Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a non-toxic and non-reactive metal that is safe for storing food. It is lightweight, durable, and has excellent temperature retention properties, making it a popular choice for food storage containers.

- Q:Are there any limitations on the width-to-thickness ratio of aluminum coils?

- Yes, there are limitations on the width-to-thickness ratio of aluminum coils. The width-to-thickness ratio is an important factor in determining the overall strength and performance of aluminum coils. If the ratio is too high, it can lead to issues such as buckling, warping, or even failure of the coil. The specific limitations on the width-to-thickness ratio depend on various factors such as the alloy composition, temper, and intended application of the aluminum coil. Different alloys and tempers have different mechanical properties and can handle different ratios. Additionally, the intended application of the coil, such as roofing, automotive, or packaging, may have specific requirements for the width-to-thickness ratio. Manufacturers typically provide guidelines and specifications for the acceptable width-to-thickness ratio based on their product offerings. These guidelines ensure that the coils are used within their intended capabilities and prevent any issues related to excessive width-to-thickness ratios. It is important for users and designers to consider these limitations and guidelines when selecting and utilizing aluminum coils. Failure to adhere to these limitations can result in compromised performance, increased risk of damage, and potential safety concerns. Therefore, it is crucial to consult the manufacturer's recommendations and industry standards to determine the appropriate width-to-thickness ratio for a given application.

- Q:How do aluminum coils contribute to energy-efficient lighting systems?

- Aluminum coils contribute to energy-efficient lighting systems by improving the heat dissipation process. When used in the construction of LED lighting fixtures, aluminum coils help in efficiently transferring heat away from the LED chips, preventing overheating and reducing energy consumption. This improved heat management ensures that the lighting system operates at optimal temperature, thereby extending the lifespan of the LEDs and enhancing overall energy efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords