ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

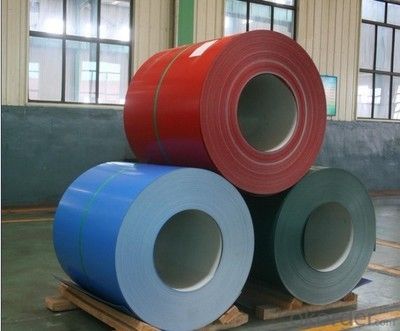

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect

- Q:How are aluminum coils processed for specific thicknesses?

- Aluminum coils are processed for specific thicknesses through a series of manufacturing steps. The process begins with the casting of molten aluminum into large ingots. These ingots are then rolled out into thin sheets using a hot rolling mill. The first step in achieving the desired thickness is hot rolling. The aluminum sheet is passed through a series of heated rollers that gradually reduce its thickness. This process is repeated multiple times, with the sheet being reheated between each pass. Hot rolling allows for the sheet to be elongated and thinned out. After hot rolling, the sheet may undergo a process called cold rolling. Cold rolling involves passing the hot rolled sheet through a set of cold rollers. This process further reduces the thickness and improves the surface finish of the aluminum. Cold rolling also increases the strength and hardness of the material. Next, the sheet is annealed, which involves heating it to a specific temperature and then allowing it to cool slowly. Annealing helps to relieve any internal stresses and improve the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. The coils can then be further processed or used in various applications, such as in the manufacturing of automotive parts, packaging materials, or building construction. Overall, the process of processing aluminum coils for specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in various industries.

- Q:A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminum Oxide Al2O3

- Q:Can aluminum coils be used in the aerospace industry?

- Yes, aluminum coils can be used in the aerospace industry. Aluminum is widely used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum coils are often used in the manufacturing of various aircraft components such as fuselage panels, wings, and structural frameworks. The coils can be easily formed into different shapes and sizes, providing flexibility in design and reducing the overall weight of the aircraft. Additionally, aluminum coils are compatible with different manufacturing processes like welding, machining, and forming, making them an ideal choice for the aerospace industry.

- Q:Why there is arc panel after aluminum coil straightening?

- The aluminum coil can only become flat and straight after being planished on stretch bender.

- Q:What are the different types of protective coatings for aluminum coils?

- There are several types of protective coatings available for aluminum coils, including polyester, polyvinylidene fluoride (PVDF), acrylic, epoxy, and polyurethane. These coatings provide varying degrees of protection against corrosion, UV rays, and other environmental factors, ensuring the longevity and durability of the aluminum coils.

- Q:What is the difference between hot rolled and cold rolled aluminum coils?

- The main difference between hot rolled and cold rolled aluminum coils lies in the manufacturing process. Hot rolled aluminum coils are produced at temperatures above the recrystallization temperature, resulting in a more malleable and ductile product. Cold rolled aluminum coils, on the other hand, are processed at room temperature, making them stronger and more rigid. This difference in processing also affects the surface finish and dimensional accuracy of the coils.

- Q:Are aluminum coils resistant to fire?

- Yes, aluminum coils are generally considered to be resistant to fire. Aluminum has a high melting point of 660 degrees Celsius, which is significantly higher than the average temperature of most household fires. This makes aluminum coils a popular choice for various applications where fire resistance is required, such as in the construction of buildings, electrical systems, and automotive components. Additionally, aluminum has a low flammability and does not produce toxic fumes when exposed to fire, further enhancing its fire-resistant properties. However, it is important to note that the fire resistance of aluminum coils can vary depending on the specific alloy used and the thickness of the coil. Therefore, it is always recommended to consult with experts or refer to industry standards to ensure the appropriate fire safety measures are taken.

- Q:94 f150. have the stock wheels which are weathered and dull. whats a good way to bring the shine back? some of the original coating is there ,most is gone. tried mothers aluminum wheel polish,does nothing. is it wise to use a wire wheel in a drill to get down to just the aluminum? the wheels are those with the center plastic cap with holes around the outer edge.thanks for any info

- I am not sure if you can sand them down an put a clear coat on them? I can say this is why you see older vehicles with plasti-dip coatings, to cover up the dings, curb rash and peeling clear coat, and the cost is lower than replacement. List your city and state. In my area there is wheel specialty shop that does tig welding repairs and will do a factory refinish. Look for one of those places. Or buy new rims and sell the old ones online.

- Q:Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q:Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a popular material choice for solar panel frames and supports due to its lightweight yet strong nature. It is corrosion-resistant, durable, and has excellent thermal conductivity, making it suitable for withstanding harsh weather conditions and efficiently dissipating heat generated by the solar panels. Additionally, aluminum is also highly recyclable, which aligns with the sustainable nature of solar energy systems. Overall, the use of aluminum coils in solar panel systems contributes to their efficiency, longevity, and environmental friendliness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords