Aluminium Checker Plate for Boat Deck Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

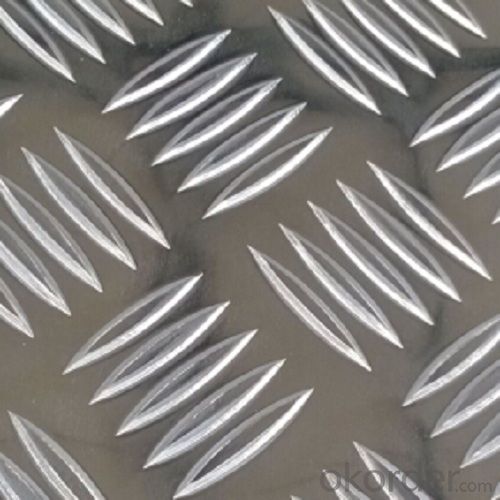

Aluminium Checker Plate for Boat Deck Use

l Product Information

1. Alloy number: 1100, 3003,1050,1060, 5052.

2. Temper: H14, H18, H12, H16, H22, H26, H24.

3. Thickness: 0.8-10.0mm. width: 20-1600mm.

4. Tolerance: thick+/-0.02mm, width +/-0.5mm.

5. Pattern: Two bars, Three bars, Five bars and Diamond.

6. Surface brightness: bright surface or normall surface.

7. Application: trailer, truck, decking, flooring, stairs, steps, building industry.

8. Loading port: Shanghai or main port.

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:What are some common applications for aluminum coils?

- Aluminum coils are widely used in various industries due to their exceptional qualities and versatility. Some common applications for aluminum coils include: 1. Construction: Aluminum coils are extensively used in the construction industry for roofing, cladding, and insulation purposes. The lightweight nature of aluminum makes it an ideal material for these applications, as it reduces the overall weight of the structure and provides excellent resistance to corrosion. 2. Transportation: Aluminum coils are widely used in the automotive and aerospace industries. In the automotive sector, aluminum coils are used in the manufacturing of heat exchangers, radiators, and condensers. They are also used to produce lightweight body panels, reducing the overall weight of vehicles and improving fuel efficiency. In the aerospace industry, aluminum coils are used to manufacture aircraft parts, including wings, fuselages, and engine components, due to their high strength-to-weight ratio. 3. Electrical and Electronics: Aluminum coils are utilized in the electrical and electronics industry for various applications. They are commonly used in the production of transformers, motors, and generators, as aluminum has excellent conductivity and is lightweight. Aluminum coils are also used in the manufacturing of electrical cables, as they provide good electrical conductivity and are resistant to corrosion. 4. Packaging: Aluminum coils are extensively used in the packaging industry due to their excellent barrier properties. They are commonly used for packaging food and beverages, pharmaceuticals, and various other consumer products. Aluminum coils provide an impermeable barrier against moisture, oxygen, and light, ensuring the preservation and protection of the packaged goods. 5. Heating, Ventilation, and Air Conditioning (HVAC): Aluminum coils are widely used in HVAC systems for their excellent heat transfer properties. They are commonly found in air conditioning systems, heat pumps, and refrigeration units. Aluminum coils provide efficient heat exchange, ensuring effective cooling and heating processes. In summary, aluminum coils find common applications in construction, transportation, electrical and electronics, packaging, and HVAC industries due to their lightweight nature, corrosion resistance, excellent conductivity, and heat transfer properties.

- Q:Can aluminum coils be used in the production of consumer electronics?

- Consumer electronics can make use of aluminum coils. Aluminum, being a versatile and lightweight metal, offers numerous advantages in the manufacturing of electronic devices. With its exceptional thermal conductivity, it is perfect for dissipating heat in components like motors, transformers, and power supplies. Aluminum coils find widespread application in smartphones, laptops, and tablets. They are commonly utilized in constructing the housing or casing of these devices, providing a durable and lightweight solution. Moreover, aluminum's non-magnetic nature makes it suitable for electronic devices that require minimal magnetic field interference. Furthermore, aluminum coils exhibit good electrical conductivity, making them valuable in applications that necessitate efficient transmission of electrical signals. They are frequently used in manufacturing antennas, connectors, and other electronic components that require high conductivity. Additionally, aluminum is highly recyclable, aligning with the increasing demand for sustainable manufacturing practices. Incorporating aluminum coils into consumer electronics not only offers functional benefits but also contributes to a greener and more environmentally friendly production process. In conclusion, aluminum coils are indeed suitable for use in the production of consumer electronics due to their exceptional thermal conductivity, lightweight and durable properties, good electrical conductivity, and recyclability.

- Q:What are the different alloy compositions used in aluminum coils?

- Aluminum coils utilize various alloy compositions, each with distinct properties and applications. Let's explore some of the commonly employed compositions: 1. The 1000 series alloys are nearly pure aluminum, boasting exceptional ductility and corrosion resistance, with a minimum aluminum content of 99%. These alloys find utility in scenarios demanding formability and efficient electrical conductivity, such as electrical wiring and packaging. 2. Manganese is present in small quantities within the 3000 series alloys, rendering them sturdier and more corrosion-resistant than their 1000 series counterparts. Cooking utensils, chemical equipment, and decorative trim are among the applications where these alloys are frequently employed. 3. Magnesium serves as the primary alloying element in the 5000 series alloys, significantly enhancing their strength and hardness. Renowned for their impressive resistance to corrosion, these alloys are commonly utilized in marine environments, as well as the automotive and aerospace industries. 4. The 6000 series alloys are combined with magnesium and silicon, leading to improved strength, heat treatability, and weldability. Architectural and structural components, transportation, and electrical conductors often rely on these alloys. 5. Zinc is the primary alloying element in the 7000 series alloys, providing them with remarkable strength and toughness. These alloys are frequently employed in high-stress environments, including aircraft structural components and sporting equipment. It is crucial to acknowledge that numerous alloy compositions are employed in aluminum coils, each tailored to specific requirements and applications. The choice of alloy composition hinges on factors such as desired strength, corrosion resistance, formability, and cost considerations.

- Q:Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q:I am looking for a deoderant that doesn't contain aluminum that actually works. I have tried Tom's natural deoderant and didn't get to use it long enough to see if it worked because it really irritated my skin and caused it to burn and peel. I have also tried the one made by Adidas and it seemed to work pretty well through the winter months, but now that it is getting warm again I'm noticing that it isn't quite doing the job anymore.

- aluminum zirconium is the chemical that makes you stop sweating, not that it works on most people. they can only put a certain percentage of it in deodorants, try the degree clinical, i just started using it and it seems to be doing okay, good luck i know what you are going through.

- Q:I am so confused right know. I want to cook something using an aluminium foil. Is the reflective side supposed to be inside or outside?

- As everyone who's answered has already told you, Saran Wrap is clear plastic. It's used to wrap left-overs and sandwiches in...although it's not totally air-tight, it comes close to it. Aluminum foil is used to cover things while you're baking or roasting them (like a turkey breast or lasagna) or it can be used on the bottom of a cookie sheet or oven rack to catch spills. It helps to radiate heat. You can also use aluminum foil to wrap things in for refrigeration. It just doesn't create the seal that Saran Wrap does.

- Q:Can aluminum coils be used in the production of cryogenic storage tanks?

- Cryogenic storage tanks can incorporate aluminum coils, as aluminum is a suitable material for such purposes. This is due to its low density, high thermal conductivity, and excellent resistance to corrosion. These attributes make it an excellent choice for the storage and transportation of cryogenic liquids like liquid nitrogen, oxygen, and argon. Aluminum coils can be utilized to construct the internal shell of the tank, which offers a lightweight and durable solution. Moreover, aluminum is highly malleable, enabling the creation of intricate tank shapes and designs. However, it is crucial to consider that aluminum has a higher coefficient of thermal expansion compared to materials such as stainless steel. Therefore, adequate design measures must be implemented to accommodate thermal contraction and expansion during cryogenic operations.

- Q:Can aluminum coils be used in refrigeration systems?

- Indeed, refrigeration systems can utilize aluminum coils. The rationale behind selecting aluminum as the preferred material for coil construction in refrigeration systems stems from its remarkable heat transfer capabilities and resistance to corrosion. Not only are aluminum coils lightweight and long-lasting, but they also excel in efficiently transferring heat, rendering them appropriate for a wide range of refrigeration applications, including air conditioning units, refrigerators, and freezers. Moreover, aluminum coils offer the advantage of being easier to mold and install in comparison to alternative materials, thus solidifying their position as the top choice among manufacturers.

- Q:How are aluminum coils processed for further fabrication?

- Aluminum coils are processed for further fabrication through a series of steps, including cleaning, annealing, leveling, slitting, and recoiling. The cleaning process removes any impurities or contaminants from the surface of the coils. Annealing involves heating and cooling the coils to enhance their ductility and make them easier to work with. Leveling ensures uniform thickness and flatness across the coils. Slitting involves cutting the coils into narrower strips of desired width, while recoiling is done to create smaller coils for specific applications.

- Q:How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. These coils are used in both the condenser and evaporator sections of the system. In the condenser, the aluminum coils help transfer heat from the refrigerant to the surrounding air. The refrigerant, which is in a high-pressure and high-temperature state after being compressed, flows through the condenser coils. As the air from the surroundings passes over these coils, the heat from the refrigerant is transferred to the air. This process helps in cooling down the refrigerant, converting it from a gas to a liquid state. The cooled liquid refrigerant then flows to the evaporator coil. In the evaporator, the aluminum coils assist in absorbing heat from the indoor air. The liquid refrigerant enters the evaporator coils, where it undergoes a phase change from liquid to gas. As the warm indoor air passes over the coils, the refrigerant absorbs the heat, cooling down the air. This cooled air is then circulated back into the room, providing a comfortable indoor environment. The aluminum coils are preferred in HVAC systems due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These properties ensure efficient heat transfer and improve the overall performance of the system. Additionally, aluminum coils are more cost-effective and environmentally friendly compared to other materials like copper. Regular maintenance and cleaning of the aluminum coils are necessary to ensure their optimal functioning. Over time, dirt, dust, and debris can accumulate on the coil surface, hampering heat transfer and reducing efficiency. Therefore, periodic cleaning is essential to maintain the performance of the HVAC system and extend the lifespan of the aluminum coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Checker Plate for Boat Deck Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords