Alloyed flat bar-steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Material: | white: |

Packaging & Delivery

| Packaging Detail: | the package of the wire rod steel for construction is standard exporting package |

| Delivery Detail: | 30d upon recipt of L/C |

Specifications

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

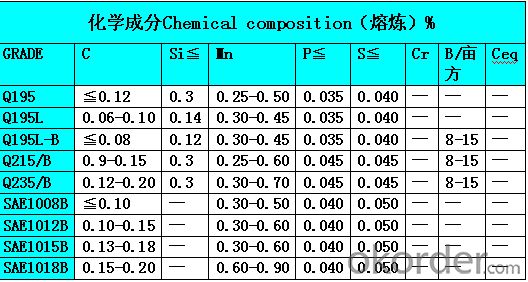

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

- Q:What are the main factors influencing the choice of steel wire rod delivery time?

- There are several key factors that influence the choice of steel wire rod delivery time. Firstly, the availability of raw materials plays a significant role. The production of steel wire rods requires various raw materials such as iron ore, coal, and scrap metal. The availability and accessibility of these materials can impact the production process and ultimately affect the delivery time. Secondly, the overall demand for steel wire rods in the market is an important factor. If there is high demand for steel wire rods, the production and delivery time may be longer due to increased order volumes. Conversely, if demand is low, suppliers may be able to deliver the product more quickly. Thirdly, the production capacity of the steel mill or manufacturer is a crucial factor. If the steel mill has limited capacity or is running at full capacity, it may take longer to fulfill orders and deliver the wire rods. On the other hand, if the production capacity is high, the delivery time may be shorter. Additionally, logistical factors such as transportation and shipping can also impact the delivery time of steel wire rods. If there are delays or disruptions in the transportation network, it may prolong the delivery process. Moreover, the distance between the steel mill and the customer's location can affect the delivery time as well. Lastly, external factors like weather conditions, labor strikes, or unforeseen events can also influence the choice of steel wire rod delivery time. These factors may cause disruptions in the production process and affect the overall delivery timeline. In conclusion, the main factors influencing the choice of steel wire rod delivery time include the availability of raw materials, market demand, production capacity, logistical factors, and external events. It is essential for manufacturers and customers to consider these factors when planning for the delivery of steel wire rods.

- Q:What are the common production processes for vanadium-coated steel wire rod?

- The common production processes for vanadium-coated steel wire rod include heating the steel rod to a specific temperature, applying a vanadium coating through either electroplating or hot-dip galvanizing methods, and then cooling and finishing the wire rod to the desired specifications.

- Q:What are the different types of steel wire rod drawing dies?

- There are several different types of steel wire rod drawing dies, each designed for specific applications and materials. 1. Single crystal diamond dies: These dies are made from a single crystal diamond and are known for their high wear resistance and durability. They are commonly used for drawing high carbon steel wires and other hard materials. 2. Polycrystalline diamond (PCD) dies: PCD dies are made from multiple small diamond grains that have been bonded together. They offer good wear resistance and are suitable for drawing medium to high carbon steel wires, stainless steel wires, and non-ferrous materials. 3. Tungsten carbide dies: These dies are made from a combination of tungsten and carbon, resulting in a material that is extremely hard and wear-resistant. They are commonly used for drawing low to medium carbon steel wires and non-ferrous wires. 4. Natural diamond dies: These dies are made from natural diamond, which offers excellent wear resistance and a smooth surface finish. They are typically used for drawing fine and ultra-fine wires, such as those used in the electronics industry. 5. PCD-coated dies: These dies have a layer of polycrystalline diamond coating applied to a tungsten carbide or steel substrate. They combine the wear resistance of PCD with the toughness of the substrate material, making them suitable for drawing a wide range of materials, including steel, stainless steel, and non-ferrous alloys. 6. Ceramic dies: Ceramic dies are made from materials such as tungsten carbide, alumina, or zirconia. They offer good wear resistance and can be used for drawing steel wires, stainless steel wires, and non-ferrous materials. Overall, the choice of steel wire rod drawing die depends on the specific application, wire material, and desired quality of the finished product. It is important to select the appropriate type of die to ensure optimal performance and longevity.

- Q:What are the growth prospects for the steel wire rod market?

- The growth prospects for the steel wire rod market are promising due to increasing demand from various industries such as construction, automotive, and manufacturing. Additionally, the growing use of steel wire rods in infrastructure development projects and the rising trend of electric vehicles are expected to further drive market growth.

- Q:How is steel wire rod used in the production of wire mesh for erosion control?

- Steel wire rod is an essential component in the production of wire mesh for erosion control. The wire rod is first passed through a series of machines to undergo a process called wire drawing, where it is stretched to a smaller diameter and shaped into a long, continuous wire. This wire is then further processed to achieve the desired thickness and strength required for erosion control applications. In the production of wire mesh for erosion control, the steel wire rod is typically woven or welded together to create a mesh structure. The wire mesh acts as a physical barrier to prevent soil erosion by holding the soil in place, especially on sloping terrain or areas prone to water flow. The wire rod's high tensile strength and durability make it an ideal material for erosion control applications. The wire mesh produced from steel wire rod is capable of withstanding harsh environmental conditions, such as heavy rainfall or strong water currents, without deforming or breaking. The wire mesh can be tailored to specific erosion control needs by adjusting the gauge and spacing of the wires. Thicker wires and smaller spacing are used for applications that require higher strength and stability, such as retaining walls or embankments. On the other hand, thinner wires and wider spacing may be suitable for less demanding erosion control situations, such as stabilizing soil on residential properties or landscaping projects. Overall, the use of steel wire rod in the production of wire mesh for erosion control provides a reliable and long-lasting solution to prevent soil erosion. Its versatility allows for customization based on specific project requirements, ensuring effective erosion control measures are implemented in various applications.

- Q:What are the different cutting methods for steel wire rod?

- There are several different cutting methods for steel wire rods, depending on the specific requirements and desired outcome. Some of the most common cutting methods include: 1. Shearing: This is a simple and widely used cutting method that involves using a pair of shears or a cutting blade to cut the wire rod. Shearing can be done manually or with the help of machinery, depending on the thickness and length of the wire rod. 2. Sawing: Sawing is another commonly used cutting method for steel wire rods. It involves using a saw blade or a band saw to cut through the wire rod. Sawing is typically used for thicker wire rods or when a precise and clean cut is required. 3. Abrasive cutting: Also known as abrasive disc cutting or abrasive wheel cutting, this method involves using an abrasive disc or wheel to grind through the wire rod. Abrasive cutting is often used for cutting thin wire rods or when a smooth and precise cut is required. 4. Flame cutting: Flame cutting, also known as oxy-fuel cutting, is a thermal cutting method that uses a combination of oxygen and a fuel gas (such as acetylene or propane) to create a high-temperature flame. The flame is directed onto the wire rod, melting and cutting through it. Flame cutting is commonly used for thick wire rods or when a fast and efficient cutting method is required. 5. Laser cutting: Laser cutting is a highly precise and efficient cutting method that uses a focused laser beam to melt and vaporize the wire rod. Laser cutting is often used for intricate and complex cutting patterns or when a high level of precision is required. These are just a few of the different cutting methods available for steel wire rods. The choice of cutting method will depend on factors such as the thickness and length of the wire rod, the desired outcome, and the available equipment and resources.

- Q:What are the main factors affecting the product differentiation of steel wire rod?

- The main factors affecting the product differentiation of steel wire rod include the quality of the raw materials used, the manufacturing process employed, the level of technological innovation, the variety of wire rod sizes and specifications offered, the presence of any specialized or unique features, and the reputation and brand image of the manufacturer. Additionally, factors such as pricing, distribution channels, customer service, and sustainability practices can also play a role in differentiating steel wire rod products in the market.

- Q:How is the global steel wire rod market expected to grow?

- The global steel wire rod market is expected to grow steadily in the coming years, primarily driven by increasing infrastructure development projects, rapid industrialization, and the rising demand for automobiles and construction materials worldwide. Additionally, the market is likely to benefit from technological advancements in steel production processes, which improve the quality and strength of wire rods. Furthermore, the expanding renewable energy sector and the growing trend towards sustainable construction practices are expected to contribute to the market's growth.

- Q:What are the safety precautions when working with steel wire rod?

- When working with steel wire rod, it is important to follow certain safety precautions to minimize the risk of accidents or injuries. Some of these precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, punctures, and impact injuries. It is also crucial to ensure a well-ventilated work area to prevent the inhalation of fumes or dust particles. Additionally, workers should be trained on proper handling techniques, such as lifting with their legs and using mechanical aids when necessary, to avoid strains or musculoskeletal injuries. Regular inspections and maintenance of tools and equipment should be conducted to identify any potential hazards or defects. Overall, adhering to these safety precautions helps create a safer working environment when dealing with steel wire rod.

- Q:What are the factors that influence the cost of steel wire rod?

- The cost of steel wire rod is influenced by various factors. These factors include the prices of raw materials, particularly iron ore and scrap metal. Fluctuations in these prices can have a significant impact on the cost of production and, consequently, the price of steel wire rod. Additionally, the demand and supply dynamics for steel wire rod in industries such as construction, automotive, and manufacturing can affect its cost. When demand is high and supply is limited, the price tends to rise. Conversely, when demand is low and supply is abundant, the price may decrease. The cost of producing steel wire rod also includes expenses such as labor, energy, transportation, and equipment maintenance. Any changes in these costs, such as wage increases or fluctuations in energy prices, can affect the final price of steel wire rod. Moreover, currency exchange rates play a role in the cost of steel wire rod. Fluctuations in exchange rates can impact the cost of importing raw materials or exporting finished products. If the domestic currency strengthens against foreign currencies, the cost may increase, leading to higher prices. Government policies and regulations, such as tariffs, import/export restrictions, and environmental regulations, can also affect the cost of steel wire rod. These factors can impact the availability of raw materials, increase production costs, or create trade barriers, all of which can influence the final cost. Furthermore, market competition in the steel wire rod industry can impact its cost. Higher competition among manufacturers can result in price competition, leading to lower prices. Conversely, if there are fewer suppliers, they may have more pricing power, resulting in higher prices. It is important to note that these factors are interconnected and can change over time. Therefore, the cost of steel wire rod is subject to constant fluctuation, influenced by a combination of these factors and market dynamics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloyed flat bar-steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords