Alkali Resistant Coated Fiberglass Soft Mesh 120g/m2 5*5mm High Strength

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

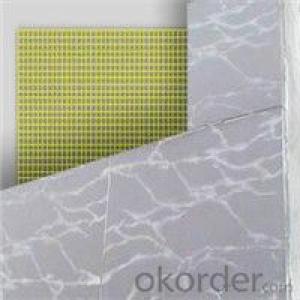

1.Structure of Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength Description:

Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength is mainly alkali-resistant fiberglass fabric, it use the C/E-glass fiber yam(main ingredient is a silicate,good chemical stability) through a special weaving techniq ,then by the antialkali and reinforcing agent etc high temperature heat finishing treatments. It's ideal engineering material inconstruction and decoration industry!

2.Main Features of Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength:

·High manufacturing accuracy

·High strength

·Good visual effect

·Factory-direct price

·Quality assured

·20years export experience

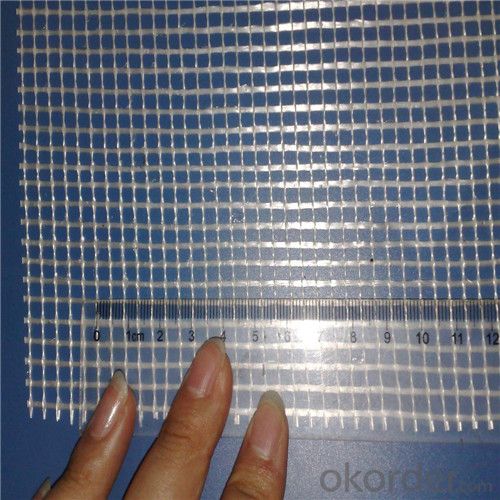

·3.Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength Images

4.Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength Specification

Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength Specifications | Roll size | |||

Aperture size(mm) | Weight/ square meter | Width | Length | |

3mm x 3mm | 45g-300g/m2 | 0.2m to 4m | 30m to 300m | |

4mm x 4mm | ||||

5mm x 5mm | ||||

6mm x 6mm | ||||

7mm x 7mm | ||||

8mm x 8mm | ||||

9mm x 9mm | ||||

Packing1: shrink plastic film then woven bag. | Package2:plastic film, then in carton box | |||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①What are we doing?

we offer the best Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength with the right price, we make the best ones on our own factory, and also offer sourcing service for many products

②What are we making in our own factory?

we are one of the best Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength supplier in China. We own and co-own the best fiberglass mesh factory, and we also make many accessories in our own factory, So we have many exclusive

products that is only available from us.

③If our MOQ is as high as the factories?

based on strong sales network and stable quality, we can sell a huge stock in a short time, so for the bestselling products, we keep a wide stock on them. So we can offer many products with a very low MOQ. This is not comparable for the factories.

④What is the packing of fiberglass mesh?

Each Alkali Resistant Coated Fiberglass Soft Mesh 140g/m2 5*5mm High Strength roll is wrapped in a shrink film or plastic bag. Then rolls are packed into cartons or pallets. products that is only available from us

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Mesh fabric with plastic glue and latex urinary two relatively better quality products than latex products produced urine glue surface is relatively soft but not broken some customers customized urine gum products according to different uses, our factory can also be customized according to customer requirements of the product corresponds to a

- Q:Can fiberglass mesh waste be recycled? What can you do if you can?

- Glass fiber mesh cloth is flame retardant products, the core material is glass fiber yarn production is completed, so has the recovery effect, which is proved that the glass fiber environmental protection that, during the two days trip I found some problems, the mesh is scrap cut, some are everywhere a throw, some is burned, there is a direct classification.

- Q:Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- Two different wall plastering joints, to play a role in cracking; generally in the amount of graphics can be directly in the report to see the amount of engineering;Wire mesh and mesh cloth each have their own uses! Specific to see your design drawings.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- Standard: to strengthen the material function and alkali fiberglass mesh cloth to external wall thermal insulation layer, the main role is: to improve the mechanical strength of the surface layer, ensure the continuity of the surface layer resistance, shrinkage pressure and insulation dispersed surface layer stress, avoid stress concentration, surface resistance nature temperature and humidity changes and accidents caused by the impact of the cracking. Therefore, alkali resistant glass fiber mesh fabric plays an important role in the external insulation system, so the selection of good glass fiber mesh fabric is also an important component to ensure the comprehensive quality of the external insulation system. The current national standard technology of exterior insulation (JG149-2003): glass fiber warp and weft resistance tensile strength shall not be less than 750N/50mm, alkali resistant tensile strength retention rate of not less than 50%, more than 130 grams of weight per square meter.

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- The difference lies in the degree of use of alkali resistant glass fiber, at present there are very few domestic high alkali glass fiber products, the difference is in the base. Because the glass itself is not alkali resistant, so in the processing of glass fiber products add alkali resistant components, adding two zirconia, the glass fiber has certain effect on tolerance -OH.The mesh fabric produced with alkali resistant glass fiber is alkali resistant grid cloth, and the others are the same

- Q:Slotted walls, seams, seams, tape, or anti mesh cloth?

- Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and will not crack, affordable, the effect is very good.

- Q:How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings. Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q:Where is fiberglass mesh better?

- Indeed, fiberglass mesh imports are good. Most of the domestic and imported goods still have a certain gap.

- Q:What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q:What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- The reason: the current domestic weaving factory method or pre roll beam weaving, and net fabric warp yarn and weft yarn is usually, roving, the intensity is greater than the warp weft. Secondly, to weave is usually weaving, woven to the continued strength of more than.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alkali Resistant Coated Fiberglass Soft Mesh 120g/m2 5*5mm High Strength

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords