AISI 4130 Alloy Steel Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 4130 Alloy Steel Round Bars

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

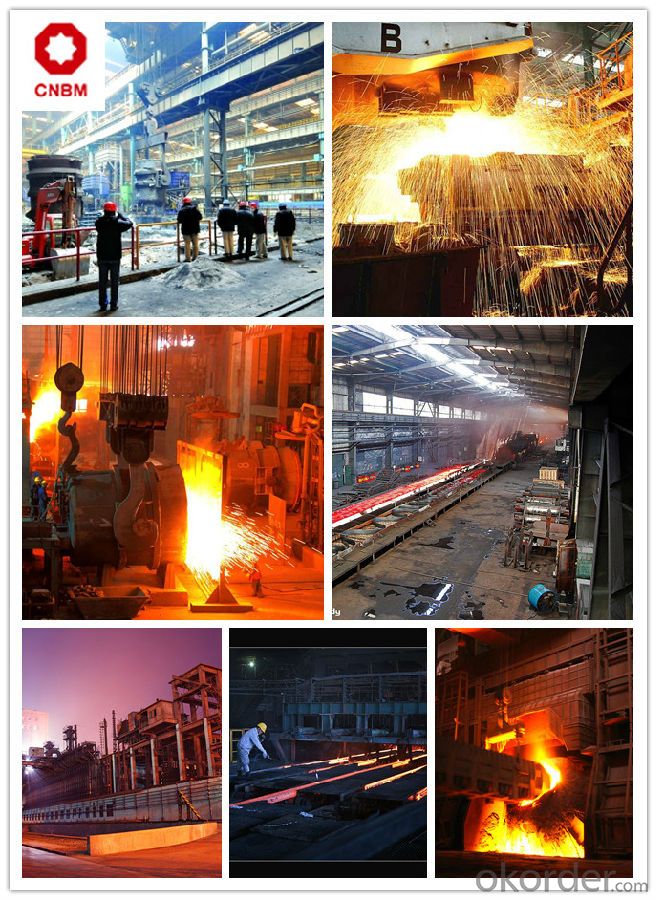

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Products Show

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q:What is the difference between a hot rolled and a turned steel round bar?

- The main difference between a hot rolled and a turned steel round bar lies in the manufacturing process and the resulting characteristics of the finished product. A hot rolled steel round bar is produced by heating a billet or ingot of steel to a high temperature and then rolling it into the desired shape. This process allows for the steel to be formed and shaped easily, resulting in a bar with a rough surface and a slightly rounded or irregular shape. Hot rolling also helps to improve the overall strength and toughness of the steel, making it suitable for a wide range of applications. On the other hand, a turned steel round bar is produced by machining a hot rolled or cold drawn bar on a lathe. This process involves removing material from the surface of the bar using cutting tools, resulting in a smooth and precise finish. Turning also allows for greater dimensional accuracy and control over the final shape and size of the bar. In terms of surface finish and dimensional accuracy, a turned steel round bar generally offers a higher level of precision compared to a hot rolled bar. The turned bar has a smoother surface with fewer imperfections, making it ideal for applications where appearance and aesthetics are important. Additionally, the turned bar typically has tighter tolerances, ensuring consistent dimensions throughout its length. The choice between a hot rolled and a turned steel round bar depends on the specific requirements of the application. Hot rolled bars are commonly used in construction, manufacturing, and general engineering applications where strength and toughness are crucial. Turned bars, on the other hand, are often used in industries such as automotive, aerospace, and precision machining, where a high level of surface finish and dimensional accuracy is required. In summary, the difference between a hot rolled and a turned steel round bar lies in the manufacturing process and the resulting characteristics. Hot rolled bars offer strength and toughness, while turned bars provide a smoother surface finish and greater dimensional accuracy. The choice depends on the specific needs of the application.

- Q:How do I calculate the length of a steel round bar based on weight?

- To calculate the length of a steel round bar based on weight, you would need to know the density of the steel and its cross-sectional area. The formula to calculate the length is weight divided by (density multiplied by cross-sectional area).

- Q:Can steel round bars be used in the manufacturing of office furniture?

- Yes, steel round bars can be used in the manufacturing of office furniture. Steel is a versatile and durable material that can be shaped into various forms, including round bars. These round bars can be used as structural components in office furniture, such as table legs, chair frames, or support beams. Steel round bars provide strength and stability to the furniture, making it suitable for heavy use in office environments. Additionally, steel can be finished in different ways, such as powder coating or chrome plating, to enhance its appearance and match the aesthetic of the office space. Overall, using steel round bars in the manufacturing of office furniture offers durability, stability, and a modern look.

- Q:Are steel round bars available in different lengths?

- Yes, steel round bars are available in different lengths.

- Q:Can steel round bars be used in the manufacturing of machinery?

- Yes, steel round bars can definitely be used in the manufacturing of machinery. Steel round bars are widely used in various industries for their strength, durability, and versatility. They are commonly used to create components such as shafts, axles, gears, and other mechanical parts that require high strength and resistance to wear and tear. Steel round bars offer excellent mechanical properties, including high tensile strength and good machinability, which make them suitable for use in heavy machinery and equipment. Additionally, steel round bars can be easily welded, forged, or machined into the desired shape, making them a preferred choice for manufacturing machinery.

- Q:What are the environmental considerations of steel round bars?

- Steel round bars pose several environmental considerations. Firstly, the extraction of iron ore, which is necessary for steel production, can have adverse effects on ecosystems and habitats. The mining process can cause deforestation, soil erosion, and the release of harmful pollutants into the air and water. In addition, manufacturing steel round bars requires a substantial amount of energy, often derived from non-renewable sources like coal and natural gas. The combustion of fossil fuels for energy contributes to greenhouse gas emissions and climate change. The steel industry is a major global emitter of carbon dioxide. Furthermore, the transportation of steel round bars also has environmental consequences. When steel products are shipped over long distances, it contributes to carbon emissions and air pollution. This is particularly significant when steel is imported or exported over vast distances. However, it is crucial to acknowledge that steel is a highly recyclable material. By recycling steel, the need for new production is reduced, energy is conserved, and the environmental impacts related to mining and extraction are decreased. By opting for steel round bars made from recycled steel, individuals and industries can contribute to a more sustainable and environmentally-friendly approach. In summary, the environmental considerations of steel round bars encompass the impacts of mining and extraction, energy consumption during production, and transportation emissions. Nevertheless, the recyclability of steel presents an opportunity to mitigate these environmental impacts and foster a more sustainable steel industry.

- Q:What are the different types of steel round bars used in the automotive suspension systems?

- There are several types of steel round bars used in automotive suspension systems, including solid round bars, hollow round bars, and torsion bars. Solid round bars are commonly used to provide stability and support to the suspension system. Hollow round bars, on the other hand, are used to reduce weight without compromising strength. Torsion bars are another type of steel round bars that are used to provide resistance to twisting forces in the suspension system.

- Q:What are the different testing methods used for steel round bars?

- The different testing methods used for steel round bars include dimensional inspection, visual inspection, ultrasonic testing, magnetic particle inspection, dye penetrant inspection, hardness testing, and chemical analysis.

- Q:What is the difference between a solid steel round bar and a hollow steel round bar?

- The main difference between a solid steel round bar and a hollow steel round bar lies in their composition and structural design. A solid steel round bar is a cylindrical rod made entirely of solid steel material, whereas a hollow steel round bar features a hollow center, creating a tubular structure. This difference in design impacts their weight, strength, and application. Solid steel round bars tend to be heavier and more robust, making them suitable for applications that require high strength and durability. On the other hand, hollow steel round bars are lighter and provide more flexibility in terms of design and application. They are often used in situations where weight reduction is necessary or for applications that require the passage of fluids or wiring through the bar's hollow center.

- Q:Difference between cold drawn round steel and round steel

- The free torsion rigidity of hot rolled steel is higher than that of cold rolled steel, so the torsion resistance of hot rolled steel is better than that of cold rolled steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI 4130 Alloy Steel Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords