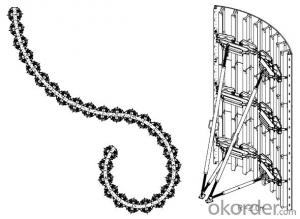

Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q:What are the common durability issues with steel formwork systems?

- Some common durability issues with steel formwork systems include rusting, corrosion, and wear and tear due to repeated use. Over time, exposure to moisture, chemicals, and harsh weather conditions can cause the steel to degrade, leading to weakened structural integrity and potential safety hazards. Regular maintenance and proper storage can help mitigate these issues and extend the lifespan of steel formwork systems.

- Q:Can steel formwork be used in sports facility construction projects?

- Yes, steel formwork can be used in sports facility construction projects. Steel formwork offers durability, strength, and versatility, making it suitable for constructing various elements in sports facilities such as stadium seating, columns, beams, and walls. Its ability to withstand heavy loads and provide a smooth finish makes it a popular choice in sports facility construction.

- Q:Can steel formwork be used for power plant construction projects?

- Indeed, power plant construction projects can utilize steel formwork. Steel formwork proves to be an adaptable and long-lasting option for crafting concrete structures across diverse sectors, including power plant construction. It presents numerous benefits, such as exceptional strength, effortless assembly and disassembly, as well as the capability to endure substantial loads and harsh weather conditions. Moreover, steel formwork can be tailored to meet the distinctive needs of power plant construction, facilitating the production of intricate and accurate concrete components. Furthermore, steel formwork can be repeatedly utilized, thereby offering a cost-efficient and environmentally-friendly alternative for power plant projects.

- Q:How is steel formwork disassembled?

- To ensure a safe and efficient removal, steel formwork is typically disassembled using a systematic approach. The process involves several steps that should be followed: 1. Begin with an inspection: Before disassembling the steel formwork, it is crucial to thoroughly inspect the structure for any signs of damage or wear. This step helps to identify potential hazards and allows for necessary repairs or replacements before starting the disassembly process. 2. Remove accessories: Start by carefully removing any accessories that are attached to the steel formwork, such as scaffolding, support beams, or tie rods. These accessories play a vital role in the stability of the formwork system, so their removal should be done with caution and control. 3. Clear concrete debris: Next, make sure to clear any concrete debris or remnants that may have adhered to the steel formwork. This can be done using tools like hammers, chisels, or wire brushes. Proper cleaning of the formwork ensures a smooth disassembly process and helps prevent any future complications. 4. Dismantle panels: Begin the process of dismantling the steel formwork panels one by one. This is typically achieved by removing the connecting pins, bolts, or screws that hold the panels together. It is important to follow the reverse order of the assembly process, starting from the top and gradually working downwards. 5. Handle and store: As each panel is disassembled, it is essential to handle it with care to avoid any damage or injury. Once disassembled, label the panels properly and store them in a designated area for easy retrieval in the future or for transportation purposes. 6. Conduct post-disassembly inspection: After the complete disassembly of the steel formwork, it is important to carry out a final inspection. This step allows for the identification of any damaged or worn-out components that may require repairs or replacement before the next use. In summary, the disassembly process of steel formwork necessitates careful planning, attention to detail, and adherence to safety guidelines. By following these steps, the formwork can be properly removed while maintaining the integrity of the structure and ensuring the safety of the workers involved.

- Q:How does steel formwork handle different concrete surface cleaning methods?

- Concrete construction projects can benefit from the durability and versatility of steel formwork. When it comes to cleaning the concrete surface, steel formwork proves to be highly effective and adaptable. Pressure washing is a common method used to clean concrete surfaces. Steel formwork can withstand the force of high-pressure water jets without sustaining any damage. The smooth and non-porous nature of the steel formwork surface facilitates the removal of dirt, debris, and other unwanted materials. By utilizing pressure washing, a smooth and even finish can be achieved. Chemical cleaning is another technique employed for cleaning concrete surfaces. Steel formwork is resistant to the majority of chemicals commonly used for cleaning purposes. This allows for the usage of various cleaning agents to eliminate stubborn stains, oil, grease, and other contaminants from the concrete surface. The chemical cleaning process can be carried out without causing any harm or deterioration to the steel formwork. Manual cleaning methods may also be utilized in certain instances. Steel formwork can withstand manual scrubbing, brushing, or scraping without any issues. The strength and durability of steel make it suitable for manual cleaning methods, which may be necessary when dealing with tough stains or debris that cannot be easily removed through other means. In conclusion, steel formwork is an ideal choice for handling various concrete surface cleaning methods. Its resistance to pressure washing, chemical cleaning, and manual cleaning ensures that the concrete surface can be effectively cleaned without damaging the formwork. This allows for a clean and visually appealing finish while maintaining the structural integrity of the formwork.

- Q:How does steel formwork affect the overall constructability of the structure?

- The overall constructability of a structure is greatly enhanced by the use of steel formwork. Firstly, the high strength and durability of steel formwork enable it to withstand the pressure and forces exerted during the concrete pouring and curing process. This strength allows for the construction of taller and more complex structures, providing greater design flexibility. Furthermore, the reusability of steel formwork significantly reduces construction time and costs. Unlike traditional wooden formwork, steel formwork can be easily dismantled, cleaned, and reassembled for future concrete pours. This eliminates the need for continuous formwork fabrication, resulting in faster construction cycles and increased productivity. In addition, steel formwork ensures excellent dimensional accuracy and stability. The rigid structure of steel formwork allows for precise pouring and shaping of concrete according to desired dimensions, resulting in a more accurate and seamless end product. This accuracy is particularly important for high-quality construction, especially in critical elements such as walls, columns, and beams. Moreover, steel formwork offers superior surface finishes and better concrete quality. Its smooth and non-absorbent surface prevents water leakage or seepage from the concrete, resulting in a higher-quality finish. This is particularly beneficial for structures that require high aesthetic appeal or exposed concrete surfaces. Lastly, steel formwork enhances safety on construction sites. Its robust structure and stability reduce the risk of accidents during the concrete pouring and formwork removal processes. Steel formwork also allows for easier access and movement of workers, ensuring safe and efficient task performance. In conclusion, steel formwork significantly improves the constructability of structures. Its strength, reusability, dimensional accuracy, surface finish, and safety benefits make it a preferred choice for construction projects. By utilizing steel formwork, construction processes become more efficient, cost-effective, and reliable, resulting in a higher-quality end product.

- Q:Can steel formwork be used in areas with limited construction equipment access?

- Yes, steel formwork can be used in areas with limited construction equipment access. Steel formwork is known for its durability and strength, making it suitable for use in remote or difficult-to-access areas. Unlike other types of formwork, steel formwork does not require extensive machinery or equipment for installation. It can be easily transported and assembled manually, reducing the reliance on heavy machinery. Additionally, steel formwork is reusable, which means it can be disassembled and moved to different locations if necessary. This versatility makes steel formwork a practical choice for construction projects in areas with limited equipment access, ensuring efficient and cost-effective construction processes.

- Q:How does steel formwork affect the overall construction site safety?

- Steel formwork is widely used in construction due to its strength, durability, and reusability. When considering its impact on construction site safety, steel formwork plays a crucial role in enhancing safety measures in multiple ways. Firstly, steel formwork provides a secure and stable structure for concrete pouring. Its rigid and robust nature ensures that the formwork remains intact during the pouring process, minimizing the risk of collapse or failure. This stability significantly reduces the likelihood of accidents such as falls, which can be detrimental to workers' safety. Moreover, steel formwork is designed to withstand high pressures exerted by the wet concrete. This capability prevents any deformation or movement of the formwork, ensuring the concrete sets in the desired shape and structure. By maintaining the integrity of the formwork, the risk of structural defects or weaknesses in the resulting concrete elements is significantly reduced, thereby enhancing overall site safety. Another significant advantage of steel formwork is its ability to be easily assembled and disassembled. This feature facilitates efficient installation and removal, reducing the time workers spend on the construction site. Minimizing the duration of construction activities also minimizes exposure to potential hazards, such as working at heights or near heavy machinery, thus improving safety conditions. Additionally, steel formwork can be customized and tailored to fit specific project requirements. This adaptability ensures precise and accurate concrete placement, reducing the need for additional modifications or alterations. By minimizing the need for rework, steel formwork helps prevent potential accidents or injuries that may arise from incorrect or faulty placements. Furthermore, steel formwork's reusability provides long-term benefits to construction site safety. Unlike traditional formwork materials, steel formwork can be reused multiple times, reducing the overall waste generated during construction. By minimizing waste, the risk of tripping hazards or material obstructions on the site is reduced, creating a safer working environment for all personnel involved. In summary, steel formwork significantly enhances construction site safety by providing stability, preventing structural defects, reducing construction time, enabling precise placements, and minimizing waste. Its robust and reliable nature ensures a secure working environment, reducing the potential risks and hazards associated with construction activities.

- Q:How does steel formwork perform in fire-resistant structures?

- Steel formwork performs well in fire-resistant structures. Steel has a high melting point and excellent fire resistance properties, making it a suitable choice for formwork in such structures. It can withstand high temperatures for longer durations without compromising its structural integrity. Additionally, steel formwork provides enhanced strength and durability, ensuring the safety and stability of the fire-resistant structure during a fire event.

- Q:How does steel formwork differ from other types of formwork?

- There are several ways in which steel formwork differs from other types of formwork. To begin with, steel formwork is renowned for its durability and long lifespan. While wooden or plastic formwork often needs to be replaced frequently due to wear and tear, steel formwork can withstand heavy use and be reused multiple times. As a result, it is a cost-effective option in the long term, as it eliminates the need for constant replacements. Furthermore, steel formwork provides a higher level of precision and accuracy in construction. Its rigid structure ensures that the concrete is poured and cured in the desired shape and dimensions. This is particularly important in projects that require high-quality finishes or intricate architectural designs. Moreover, steel formwork offers excellent structural support. It can endure the pressure exerted by wet concrete without deforming or collapsing, thus ensuring the stability and safety of the construction process. This is especially vital in large-scale projects or situations involving high volumes of concrete. In addition, steel formwork is versatile and easily customizable to meet specific project requirements. It can be swiftly assembled and disassembled, enabling quick and efficient construction processes. Steel formwork can also be adjusted to accommodate various shapes and sizes, making it suitable for a wide range of construction projects. Lastly, steel formwork is highly resistant to weather conditions and environmental factors. Unlike wooden formwork, which may warp or deteriorate when exposed to moisture, steel formwork remains stable and unaffected by changes in temperature or humidity. Consequently, it is suitable for both indoor and outdoor construction projects. In conclusion, steel formwork distinguishes itself from other formwork types due to its durability, precision, structural support, versatility, and resilience to environmental factors. It offers numerous advantages that make it a preferred choice for many construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords