Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

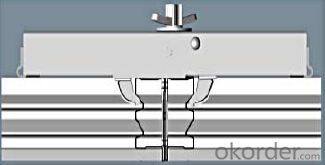

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:What are the different types of reinforcement systems used with steel formwork?

- Steel formwork in construction projects commonly employs various types of reinforcement systems to enhance strength and stability. These systems aim to withstand the weight of concrete and other loads. Rebar, or steel bars/rods, represents a prevalent reinforcement system. It is typically positioned horizontally and vertically within the formwork, forming a grid-like structure. This arrangement evenly distributes concrete weight and prevents potential cracks or failures. Wire mesh or welded wire fabric serves as another reinforcement system. It comprises a grid of wires laid over the formwork before concrete pouring. The wire mesh reinforces the concrete, providing added strength and durability. Sometimes, steel formwork incorporates precast concrete elements as reinforcement. Precast beams or columns are placed within the formwork to enhance support and reinforcement. Certain formwork systems utilize post-tensioning techniques for reinforcement. This involves the installation of steel cables or bars within the formwork, applying tension after concrete pouring. This technique heightens the formwork and structure's strength and stability. Ultimately, the selection of a reinforcement system depends on project-specific requirements, such as load capacity, design specifications, and desired durability. By employing appropriate reinforcement systems, steel formwork can achieve greater strength and reliability, ensuring project success and safety.

- Q:How does steel formwork affect the overall construction waste management?

- Steel formwork is known for its durability and reusability, which can significantly impact the overall construction waste management in a positive way. Firstly, steel formwork can be reused multiple times, reducing the need for new formwork materials for each construction project. This reduces the amount of waste generated during construction, as well as the demand for raw materials, such as timber, which are often used in traditional formwork systems. Additionally, steel formwork is known for its high strength and stability, allowing for efficient and precise construction. This reduces the likelihood of errors or mistakes during the construction process, resulting in less rework and waste. Furthermore, steel formwork can be easily dismantled and reassembled, allowing for flexibility in design and construction, and minimizing waste that would otherwise be generated from fixed or permanent formwork systems. Moreover, steel formwork is recyclable at the end of its life cycle. Steel is one of the most recycled materials globally, and the recycling process for steel is energy-efficient and has minimal environmental impact. By choosing steel formwork, construction projects can contribute to a circular economy by ensuring that the materials used in construction can be recycled and reused rather than ending up in landfills. In conclusion, steel formwork positively affects overall construction waste management by reducing the amount of waste generated during construction, minimizing the demand for new materials, enabling efficient construction processes, and promoting recycling at the end of its life cycle. These advantages make steel formwork a sustainable choice for construction projects, helping to minimize environmental impact and promote responsible waste management practices.

- Q:Are there any disadvantages to using steel formwork?

- Yes, there are a few disadvantages to using steel formwork. Firstly, steel formwork is generally more expensive to purchase and maintain compared to other types of formwork materials. Additionally, steel formwork is heavier and more difficult to handle and transport, which can increase labor costs and project timelines. Furthermore, steel formwork requires skilled labor for assembly and dismantling, adding to the overall project costs. Lastly, steel formwork may not be suitable for all types of construction projects, especially those involving complex or irregular shapes.

- Q:How does steel formwork accommodate for different concrete curing temperatures?

- Steel formwork is a versatile and reliable option for accommodating different concrete curing temperatures. The main advantage of steel formwork is its high thermal conductivity, allowing it to effectively dissipate heat from the curing concrete. This property enables the steel formwork to regulate the temperature of the concrete during the curing process. In situations where the concrete curing temperature needs to be controlled, steel formwork can be equipped with additional features to accommodate these requirements. For instance, insulation materials can be applied to the steel formwork to minimize heat loss or gain, ensuring a steady and consistent curing temperature. This is particularly useful in extreme weather conditions, where the ambient temperature can significantly impact the curing process. Moreover, steel formwork can also be used in conjunction with heating or cooling systems to further regulate the concrete curing temperature. For example, in cold weather conditions, heating elements can be integrated into the steel formwork to maintain a favorable temperature for proper curing. Similarly, in hot weather conditions, cooling systems can be employed to prevent excessive heat from affecting the curing process. Additionally, steel formwork offers excellent strength and durability, which is crucial for accommodating different concrete curing temperatures. The robust nature of steel formwork allows it to withstand the pressure and stresses exerted by the curing concrete, regardless of the temperature. This ensures that the formwork remains intact and stable throughout the curing process, preventing any deformations or failures that may compromise the quality of the concrete structure. Overall, steel formwork is an ideal choice for accommodating different concrete curing temperatures due to its high thermal conductivity, adaptability to insulation materials, and compatibility with heating or cooling systems. Its strength and durability further enhance its ability to withstand the challenges posed by varying curing temperatures, ensuring the successful and optimal curing of the concrete.

- Q:What are the different types of steel formwork supports?

- There are several types of steel formwork supports, including adjustable steel props, steel beams, steel frames, and steel tubes.

- Q:How does steel formwork handle different concrete reinforcement types?

- Steel formwork is a versatile and durable option for handling different types of concrete reinforcement. It is commonly used in construction projects to create temporary molds or structures to hold concrete in place during the pouring and curing process. One of the advantages of steel formwork is its ability to handle different concrete reinforcement types. Whether it is traditional reinforcement such as steel bars or modern reinforcement techniques like fiber-reinforced polymers (FRP), steel formwork can accommodate them all. Steel formwork is designed to be strong and rigid, which allows it to support the weight and pressure exerted by different types of reinforcement materials. Whether it is the weight of steel bars or the tensile strength of FRP, steel formwork can withstand these forces without deforming or collapsing. Additionally, steel formwork is highly adaptable and can be easily adjusted or modified to accommodate different reinforcement types. It can be cut or welded to create openings or recesses for steel bars or other reinforcement materials to pass through. This flexibility ensures that steel formwork can be customized to suit the specific needs of each construction project. Furthermore, steel formwork offers a smooth and even surface finish, which is crucial for ensuring proper adhesion between the concrete and the reinforcement materials. This ensures that the reinforcement is securely embedded within the concrete structure, providing the necessary structural integrity and strength. In conclusion, steel formwork is a reliable and effective solution for handling different concrete reinforcement types. Its strength, adaptability, and ability to provide a smooth surface finish make it an ideal choice for construction projects that require diverse reinforcement materials.

- Q:How does steel formwork affect the overall construction site waste recycling?

- The overall waste recycling at a construction site can be greatly influenced by steel formwork. In contrast to traditional timber formwork, steel formwork is more long-lasting and can be reused multiple times. This results in a decrease in waste production at the construction site since there is less necessity for the production and disposal of new formwork materials. Furthermore, cleaning and maintaining steel formwork is simpler, which extends its lifespan and reduces the need for replacement. This not only decreases waste but also saves costs associated with purchasing new formwork materials for each construction project. Moreover, steel formwork is highly recyclable. Once its life cycle is complete, it can be recycled and utilized to manufacture new steel products, diminishing the demand for fresh materials and reducing the environmental impact. Through the utilization of steel formwork, construction sites can greatly diminish their waste generation and contribute to a more sustainable construction industry. This not only benefits the environment but also promotes a more efficient and cost-effective approach to construction.

- Q:Can steel formwork be used in seismic-prone areas?

- Yes, steel formwork can be used in seismic-prone areas. Steel is a strong and durable material that can withstand the forces generated during earthquakes. It provides excellent structural stability and can be easily reinforced to meet the specific requirements of seismic design codes. Additionally, steel formwork offers the advantage of being reusable, making it a cost-effective and practical option for construction projects in seismic-prone areas.

- Q:How does steel formwork affect the overall dimensional stability of a structure?

- Steel formwork can significantly enhance the overall dimensional stability of a structure. Due to its strength and rigidity, steel formwork provides excellent support to the concrete during the pouring and curing process. This ensures that the structure maintains its desired shape and dimensions without any significant deformation or dimensional changes. Additionally, steel formwork has minimal expansion and contraction properties, which further contributes to the stability of the structure. Overall, the use of steel formwork helps in achieving accurate and consistent dimensions, resulting in a structurally sound and stable building.

- Q:Can steel formwork be used in underground structures?

- Underground structures can indeed utilize steel formwork. This material proves to be highly versatile and durable, capable of withstanding the demanding conditions underground. Its exceptional strength and stability make it ideal for constructing walls, columns, and slabs in subterranean spaces. One major advantage of steel formwork lies in its ability to resist the pressure exerted by the surrounding soil and water. Underground structures often encounter significant hydrostatic pressure, yet steel formwork remains resilient and free from deformation or collapse. This ensures the structure's safety and stability. Moreover, steel formwork is reusable, making it a cost-effective option for underground construction projects. Its robust nature allows for multiple uses, reducing the need for frequent replacements and lowering overall construction costs. Furthermore, steel formwork offers design flexibility, easily customizable to meet specific project requirements. It can be shaped and sized to create intricate geometries within underground structures. However, it is crucial to note that steel formwork necessitates proper surface treatment to safeguard against corrosion in the underground environment. Special coatings or galvanization can be applied to prevent rusting and extend the formwork's lifespan. In conclusion, steel formwork proves to be a suitable choice for underground structures due to its strength, durability, reusability, and design flexibility. It effectively withstands the challenges posed by the underground environment, guaranteeing long-term stability and safety for the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords