Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

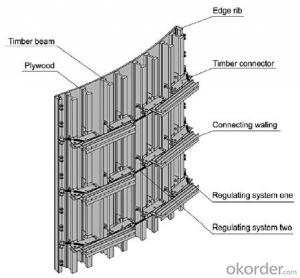

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q:Can steel formwork be used for precast concrete walls?

- Yes, steel formwork can be used for precast concrete walls. Steel formwork provides strength, durability, and stability, making it suitable for creating high-quality precast concrete walls. Its versatility allows for a wide range of designs and shapes, making it a popular choice in the construction industry.

- Q:How does steel formwork handle concrete vibration and air entrapment?

- Steel formwork is highly effective in handling concrete vibration and minimizing air entrapment during the pouring and curing process. Firstly, steel formwork is known for its high strength and rigidity, which allows it to withstand the intense vibrations caused by concrete compaction. When concrete is poured into steel formwork, the formwork itself acts as a barrier, preventing excessive movement or deformation that could lead to the formation of voids or air pockets. This ensures that the concrete is evenly distributed and compacted throughout the structure. Additionally, steel formwork is designed with tight joints and smooth surfaces, which helps in reducing air entrapment. The joints are tightly sealed to prevent any leakage, which could result in air being trapped within the concrete. This is particularly important as air pockets can weaken the structural integrity and durability of the concrete. The smooth surfaces also aid in the easy flow and consolidation of the concrete, reducing the chances of air entrapment. Furthermore, steel formwork can be easily customized and adjusted to fit the specific requirements of the construction project. This allows for precise and accurate placement of the formwork, ensuring that the concrete is poured and compacted in the desired manner. By having complete control over the formwork, the risk of air entrapment can be minimized, resulting in a more durable and reliable concrete structure. In conclusion, steel formwork is an excellent choice for handling concrete vibration and air entrapment. Its strength, rigidity, tight joints, and smooth surfaces provide the necessary stability and control during the pouring and compaction process. By using steel formwork, construction professionals can ensure that the concrete is properly consolidated and free from air pockets, resulting in a high-quality and long-lasting structure.

- Q:How does steel formwork contribute to the overall durability of the structure?

- The construction industry relies on steel formwork as a crucial element that greatly enhances the durability of structures. This is primarily due to the inherent strength and durability of steel itself. Steel formwork is crafted from high-quality steel, renowned for its exceptional strength and resilience. The sturdiness of steel formwork enables it to withstand the immense pressure exerted by concrete during the pouring and curing processes. This is especially important for large-scale structures, where the load of concrete can be substantial. Steel formwork provides essential support to ensure that the concrete maintains its shape and form, preventing any deformations or cracks from occurring. Additionally, steel formwork exhibits high resistance to corrosion, a significant concern for construction materials exposed to moisture and environmental factors. This resistance to corrosion ensures that the formwork remains intact and retains its strength over time, even in harsh conditions. By preventing corrosion, steel formwork safeguards the structural integrity of the concrete by avoiding any potential damage caused by rusting or deterioration. Furthermore, steel formwork is known for its reusability, setting it apart from traditional timber formwork. Unlike timber formwork, steel formwork can be used multiple times, reducing the need for constant replacement. This not only saves costs but also minimizes waste and promotes sustainable construction practices. The ability to reuse steel formwork guarantees that the structural elements of a building remain consistently strong and durable throughout the entire construction process. Moreover, steel formwork provides a smooth surface finish to the concrete, enhancing the overall aesthetics of the structure. This smooth finish reduces the necessity for additional surface treatments, saving time and resources during construction. Additionally, it improves the durability of the structure by minimizing the risk of cracks and imperfections, which can compromise the overall integrity of the construction. In conclusion, steel formwork plays a vital role in enhancing the overall durability of structures due to its strength, corrosion resistance, reusability, and ability to provide a smooth surface finish. By providing reliable support during concrete pouring, maintaining its structural integrity over time, and enhancing the aesthetics of the building, steel formwork ensures that the structure remains durable and resilient for years to come.

- Q:What are the advantages of using modular steel formwork systems?

- There are several advantages of using modular steel formwork systems. Firstly, these systems are highly durable and can be reused multiple times, leading to cost savings in the long run. Secondly, they provide accurate and precise results, ensuring consistency in construction projects. Additionally, modular steel formwork systems offer flexibility and can be easily adjusted or customized to meet specific project requirements. They also enhance productivity as they can be quickly assembled and disassembled, saving time and labor. Moreover, these systems provide a smooth and high-quality finish to concrete structures. Overall, the advantages of using modular steel formwork systems include durability, cost-effectiveness, accuracy, flexibility, productivity, and superior finish.

- Q:What are the different types of tie systems used in steel formwork?

- There are several different types of tie systems that are commonly used in steel formwork in construction projects. These tie systems are designed to provide stability and support to the formwork during the concrete pouring process. Some of the main types of tie systems used in steel formwork include: 1. Tie rods and wing nuts: This is the most commonly used tie system in steel formwork. It consists of steel rods that are inserted through the formwork panels and secured with wing nuts. This system allows for quick and easy assembly and disassembly of the formwork. 2. Shear connectors: Shear connectors are used in situations where there is a need to transfer shear forces between the formwork and the concrete. These connectors typically consist of steel bars that are embedded in the concrete and connected to the formwork. 3. Steel form ties: Steel form ties are used to hold the formwork panels together and maintain the desired shape and alignment during concrete pouring. These ties are typically made of steel and are available in various lengths and sizes to accommodate different formwork requirements. 4. Adjustable formwork systems: These systems are designed to provide flexibility in adjusting the formwork to different shapes and sizes. They often incorporate adjustable brackets and clamps that allow for easy and precise alignment of the formwork panels. 5. Stay-in-place formwork systems: Stay-in-place formwork systems are designed to remain in place after the concrete has cured, eliminating the need for formwork removal. These systems are typically used in applications where the formwork is intended to become a permanent part of the structure, such as in bridges or tunnels. Overall, the choice of tie system in steel formwork will depend on factors such as the project requirements, structural design, and the specific conditions of the construction site. It is important to select a tie system that can provide the necessary stability and support for the formwork, while also considering factors such as ease of installation, reusability, and cost-effectiveness.

- Q:Can steel formwork be used for both reinforced and unreinforced concrete structures?

- Both reinforced and unreinforced concrete structures can utilize steel formwork. This versatile and durable option can be easily assembled and disassembled for a variety of construction projects. It provides a sturdy and inflexible framework for pouring concrete, ensuring that the concrete remains in place until it cures and gains sufficient strength. Steel formwork is particularly advantageous for reinforced concrete structures as it can withstand the additional weight and pressure of reinforcement bars and mesh. The formwork can be designed to accommodate the specific reinforcement requirements of the structure, enabling proper placement and alignment of the reinforcement elements. Similarly, steel formwork can be employed for unreinforced concrete structures. In this scenario, the formwork acts as a temporary mold that holds the concrete in the desired shape until it solidifies. The steel formwork aids in achieving precise dimensions and finishes, guaranteeing that the final concrete structure meets the desired specifications. To summarize, steel formwork is a suitable choice for both reinforced and unreinforced concrete structures. Its strength, durability, and flexibility make it a preferred option for a wide range of construction projects, providing a reliable and efficient solution for creating high-quality concrete structures.

- Q:What are the different types of formwork spacers used in steel formwork?

- Various types of formwork spacers are commonly utilized in steel formwork. These spacers play a crucial role in maintaining the desired spacing between the formwork and reinforcement, thus ensuring the structural integrity of the concrete structure. Here, we present a range of formwork spacers frequently employed in steel formwork: 1. Plastic Spacers: Due to their lightweight nature, durability, and easy installation, plastic spacers are extensively employed in steel formwork. They are typically crafted from top-notch plastic materials and come in diverse shapes and sizes to accommodate different reinforcement requirements. 2. Steel Spacers: Steel spacers are another prevalent type of formwork spacer used in steel formwork applications. Constructed from high-strength steel, they possess the capacity to withstand heavier loads. Steel spacers prove ideal for heavy-duty applications that necessitate added strength and durability. 3. Rubber Spacers: In steel formwork, rubber spacers are employed to provide a cushioning effect and prevent direct contact between the reinforcement and the formwork. These spacers are suitable for scenarios where vibration or movement is anticipated, as they efficiently absorb shocks and minimize the risk of damage. 4. Concrete Spacers: Concrete spacers primarily find utility in precast concrete applications. Comprised of concrete, they act as support structures, ensuring the correct spacing between the formwork and reinforcement is maintained. Concrete spacers are not only durable and easy to install but also offer exceptional stability during the casting process. 5. Combination Spacers: Combination spacers are versatile in nature, incorporating various materials such as plastic and steel to provide enhanced strength and stability. These spacers are designed to meet specific project requirements and offer a cost-effective solution for various steel formwork applications. To guarantee optimal performance and safety, it is imperative to select the appropriate formwork spacer type based on the project's specific requirements, encompassing load capacity, spacing needs, and environmental conditions. Seeking guidance from a structural engineer or construction professional can ensure the correct selection and installation of formwork spacers.

- Q:How does steel formwork contribute to the structural stability of the concrete elements?

- Steel formwork is utilized in the construction process to provide support and shape to concrete elements. It plays a critical role in maintaining the structural stability of these elements. To begin with, steel formwork offers a rigid and stable framework for the concrete, preventing any deformation or movement during the pouring and curing stages. This is vital as it allows the concrete to set and harden in the desired shape and position. Without proper support, the concrete may slump or sag, resulting in compromised structural integrity. Moreover, steel formwork is engineered to withstand the high pressure exerted by the wet concrete. The steel panels or frames are durable and strong enough to endure the weight of the concrete and any external forces that may be applied. This capability is particularly important in cases of tall or complex structures where the concrete may be subject to significant loads. Furthermore, steel formwork allows for precise shaping of the concrete elements. The steel panels or frames can be easily adjusted and aligned to the desired dimensions, ensuring that the final concrete structure adheres to the design specifications. This level of accuracy is crucial for the overall structural stability of the concrete elements as any inconsistencies or deviations can compromise the load-bearing capacity. Additionally, steel formwork enables efficient and effective construction processes. It can be easily assembled, disassembled, and reused, reducing construction time and costs. Furthermore, the smooth surface of the steel formwork provides a high-quality finish to the concrete elements, eliminating the need for additional treatments or formwork. In conclusion, steel formwork significantly contributes to the structural stability of concrete elements. Its rigid and stable support ensures that the concrete sets and hardens in the desired shape, while its strength and durability withstand the pressure and loads exerted by the concrete. The precise shaping capabilities of steel formwork guarantee the alignment and dimensions of the concrete structure, and its efficiency and effectiveness streamline the construction process.

- Q:How does steel formwork contribute to the safety of construction workers?

- Steel formwork contributes to the safety of construction workers in several ways. Firstly, steel formwork is known for its durability and strength, which provides a stable and secure working platform for construction workers. This stability minimizes the risk of accidents or injuries caused by unstable or collapsing structures. Additionally, steel formwork is designed to be fire-resistant, offering an added layer of protection in case of fire hazards on construction sites. This not only safeguards the workers but also helps to prevent the spread of fire to neighboring structures. Furthermore, steel formwork is often prefabricated and can be easily assembled and disassembled, reducing the time workers spend on-site and minimizing their exposure to potential hazards. The ease of assembly also ensures that the formwork is properly installed, eliminating the risk of weak or faulty structures that could pose a threat to workers. Moreover, steel formwork is designed with safety features such as handrails, guardrails, and non-slip surfaces. These features provide additional protection to workers, preventing falls and accidents while working at heights or on elevated platforms. Lastly, steel formwork is designed to withstand external forces such as wind, earthquakes, or heavy loads, making it more resistant to structural failures. This resilience reduces the risk of accidents and injuries caused by structural collapses, providing a safer working environment for construction workers. In summary, steel formwork contributes significantly to the safety of construction workers by offering stability, fire resistance, ease of assembly, safety features, and resilience to external forces. These features ensure that workers can carry out their tasks in a secure environment, minimizing the risks associated with construction activities.

- Q:Is steel formwork suitable for projects with high formwork complexity?

- Steel formwork is a great option for projects that have intricate formwork needs. It can be customized and shaped to meet the requirements of complex projects, making it ideal for structures that are curved or non-standard. Furthermore, steel formwork is strong and durable, able to withstand the pressures and loads of construction. This makes it suitable for projects that require heavy reinforcement or large concrete pours. Additionally, steel formwork provides smooth and uniform surfaces, resulting in high-quality finishes. While it may require a higher initial investment, its long lifespan and reusability make it a cost-effective choice. Overall, steel formwork is a flexible, strong, and durable option that can provide high-quality finishes for complex projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Arced Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords