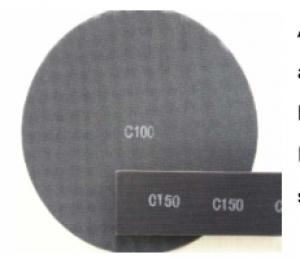

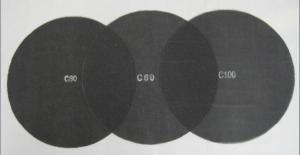

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q:Is there any place seeling the geomembrane of 20 multiplying 20?

- The 20 * 20 should refers to the length and width of the geomembrane.

- Q:Do I need to remove the existing 1 ceramic tiles in the shower stall, or can I apply the new 8 ceramic tiles right on top of the old ones? The sides are drywall, but the floor of the stall has 1 tiles that look like a pain to remove.

- The reason 1 tiles were used in your shower base is to achieve the slope neccesary for the water run-off to the drain. You will be hard-pressed to accomplish this with 8 tiles. You can adhere new tile to old with epoxy-based mastic, but I would recommend consulting with a pro to get your water properly emptying into the drain.

- Q:What are the advantages of using geocells in green infrastructure?

- Geocells offer several advantages when used in green infrastructure. Firstly, they provide effective erosion control by preventing soil movement and retaining sediments, thus promoting the stability of slopes and preventing soil erosion. Secondly, geocells enhance the load-bearing capacity of soil, enabling the construction of stronger and more durable green infrastructure systems such as green roofs, permeable pavements, and retaining walls. Additionally, geocells promote vegetation growth by providing a stable and nutrient-rich environment for plant roots. This helps in creating sustainable and aesthetically pleasing green spaces. Lastly, geocells are cost-effective and relatively easy to install, making them a practical choice for green infrastructure projects.

- Q:Buy marble boss said light-colored marble with a long time will be black, if the marble I would like to use the yellow series do not know will not be the problem, but the artificial stone looked too fake, worried about deformation but I want to buy Of the artificial stone 380 per square is not cheap

- It is recommended to use marble, but also the use of dark marble, because the windowsill position is often easy to exposure, so light-colored stone is not obvious, but will not turn black. Because it is in the windowsill, not the kitchen, the bathroom where these stains exist, so you can not consider how much stains to penetrate, if there is no longer as long as there is a long time, basically infiltration of this kind of thing is rare, as long as early Clean up. Specifically to see their own level of consumption decisions. If the economy allows you to consider marble, if it is not allowed to consider artificial stone. But the two stones are also part of the expensive part of the cheap, in general, artificial stone price cheaper than natural marble, natural marble on the price a little expensive, but the feeling will look a lot of natural, according to their own consumption level to decide, but that Natural marble has a certain degree of radiation, this is also to be considered.

- Q:Are container houses suitable for small businesses?

- Yes, container houses can be suitable for small businesses. They offer cost-effective and flexible options for office spaces or retail establishments. Container houses can be customized to meet specific business needs, are portable, and can be set up quickly. Additionally, they provide a unique and modern aesthetic that can attract customers.

- Q:What are the densities of tiles and cement

- The combination of lignocellulosic and Portland cement produces a non-toxic building material plate that does not contain any volatile toxic substances such as asbestos and formaldehyde. Wood fiber cement board will not produce any harmful substances, excellent environmental performance. Wooden cement board contains 71% Portland cement, 19% mineralized wood fiber, 9% moisture and 1% binder. Wood fiber cement board conforms to ASTM E 136 non-flammable building materials standard, excellent structural performance. Soaked in water is not layered, stable uniformity. Wooden cement board can be cut, planing, grinding, drilling, threading, and can be fixed with nails or screws.

- Q:Polyester short wire geotextile 300 grams of water ministry indicators

- Polyester short wire geotextile 300 grams of water ministry indicators and GB indicators are the same. Can be implemented in accordance with GB / T-2008 standards. 300g polyester short wire geotextile per unit area quality deviation required ± 7%. 300g polyester short wire geotextile thickness ≥ 2.4mm. 300g polyester short wire geotextile width deviation of ± 0.5%. 300g polyester short wire geotextile breaking strength ≥ 9.5KN / m. 300g polyester short wire geotextile elongation at 25% to 100%. 300g polyester short wire geotextile CBR burst strength ≥ 1.5KN. 300g polyester short wire geotextile equivalent pore size 0.07mm ~ 0.2mm. 300g polyester short wire geotextile vertical permeability coefficient (1.0 ~ 9.9) * (10 negative square ~ 10 negative three times). 300g polyester short wire geotextile tear strength ≥ 0.24KN.

- Q:What are the key considerations for selecting the appropriate steel frame formwork system for projects with limited construction budgets?

- When selecting a steel frame formwork system for projects with limited construction budgets, there are several key considerations to keep in mind. Firstly, it is important to evaluate the cost-effectiveness of the system. This includes assessing the initial cost of the formwork, as well as any additional expenses such as transportation, installation, and maintenance. Secondly, the durability and lifespan of the system should be considered to ensure it can withstand the demands of the project without requiring frequent repairs or replacements. Additionally, the versatility and adaptability of the formwork system should be taken into account, as it should be able to accommodate various types of structures and design requirements. Lastly, the availability and accessibility of the system should be considered, as it should be easily procurable within the limited budget and readily available for use. By considering these factors, one can select an appropriate steel frame formwork system that meets both the budgetary constraints and construction needs of the project.

- Q:Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Certainly! When installing tile or stone, it is highly recommended to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water from seeping into the underlying layers and causing damage. It is especially beneficial in wet areas, such as bathrooms, showers, and kitchen backsplashes. There are different types of waterproofing membranes available, such as liquid-applied, sheet, and fabric membranes. These can be applied to the substrate before installing the tile or stone, creating a waterproof layer that keeps the area dry and free from water-related issues. In addition to safeguarding against water damage, a waterproofing membrane also helps to prevent the growth of mold and mildew, which can be detrimental to both the installation and the health of those using the space. It is essential to note that proper installation of the waterproofing membrane is crucial for its effectiveness. Following the guidelines and best practices provided by the manufacturer ensures a tight seal and complete coverage. Overall, integrating a waterproofing membrane with tile or stone installations is a prudent decision. It enhances the project's durability and longevity while providing peace of mind against potential water damage.

- Q:How do I go about getting my real estate license in CT? Everything I have searched so far has not been too helpful, so anything will be appreciated.

- I'm assuming you live in CT. Why not just go talk to a local Broker. I Googled real estate brokers in Connecticut and found no shortage of listings--but you could narrow it down to your city. You can call them or visit them in person. They should be able to point you in the right direction. Here is some info for the National Association of Realtors in Connecticut. Call them, they also may be able to help you. Mailing Address Connecticut Association of REALTORS?, Inc. 111 Founders Plaza, Suite 1101 East Hartford, CT 06108 Phone: (860) 290-6601 Toll Free: (800) 335-4862 Fax: (860) 290-6615

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords