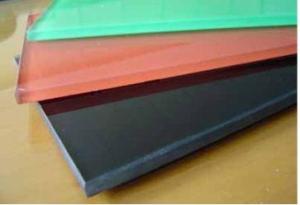

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

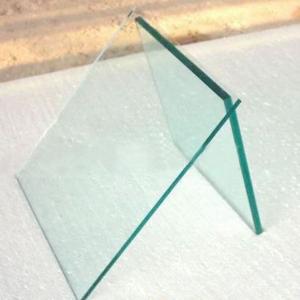

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions. Maximum processing size: 2500 mm * 8000 mm Minimum processing size: 200 mm * 300 mm The range of glass thickness: 6.38mm to 50 mm Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass. Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively. Laminated glass A. The selection of suitable float glass pane in storage Access to the next process after the quality inspection of float glass B. The measurements of glass to be cut as customized C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection D. Cleaning by deionized water

Access to the next stage after cleaning the glass E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass F. Cleaning by deionized water Access to the next stage after cleaning the glass G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling I. Inspection during the production process J. Vacuumizing treatment in autoclave

Inspection during the production process K. For subsequent processing and Packaging L. Leading Time:10 days for an average area of 1000 square meters tempered glass M. Trade terms: FOB and CIF. N. Payment Terms: By TT, 30% deposit to start producing, full amount balance paid before delivery. O. Loading and transport |

- Q:How to build a glass water wall?

- There are so many different types. It would depend on what type of fall you are looking for. Please add details.

- Q:I am making a stained glass panel with a lighthouse in it and I want to put windows and doors in the lighthouse. Do I cut them out somehow or put something over the glass

- First the negative bits:- An outdoor wedding would save lighting but risks bad weather and also some guests may not be able to hear well if there is any wind. The set-up costs of this also have to be taken into account and may well be more expensive and create more vehicle emissions than a church or hall wedding venue. Transport is the main emitter of un-green pollution which is under the control of individuals, followed by un-necessary lighting (e.g. upward facing floodlights that mainly light the bottom of clouds). For example: It's very sweet to have a wedding on a tropical beach or a Carribean island; but the CO2 emissions (as well as the cost) of getting everyone there is obscene. If you have to shuttle the wedding party between venues then hiring a bus would be ok. It would also make parking easier at the reception - but where would the guests leave their cars at the wedding venue? Would they be safe? Also, what about those who want to leave at different times? There's always some who don't want (or can't) wait around to the end of the festivities. Now the positive bits:- It would be a Green decision if you had the sites adjacent or in easy walking distance of each other. It's not everyone's cup of tea, but to go green why not have the wedding in a venue local to where the majority of the guests live. You could try asking the bridesmaids to use second-hand dresses instead of having specially made gowns. This isn't as mean as it seems - it's eliminating waste on the production and materials for clothes that would otherwise only be worn once ( the bride's dress is the natural exception). Best of all to go Green would be not to fly anywhere for your honeymoon. If you're travelling beyond a hundred miles then go by train (the greenest of all transport except for a bicycle). Try spending your wedding night in a railway sleeper compartment. That could actually be extremely romantic (James Bond always makes it seem so) and the train crew will make a big fuss of you.

- Q:The state is the number of buildings above the tempered glass

- Tilt the installation window, all kinds of ceiling (including skylights, lighting top), ceiling;

- Q:What is the difference between the span on the architectural glass and the width of the glass?

- Width, refers to the size of a single piece of glass, that is, between the size of the two sides of the box

- Q:Lanzhou Huazhong hollow glass factory where

- I was in Chengdu, Sichuan State-level economic and technological development zone of glass deep processing enterprises, in our park also Huacao building materials, and its enterprises mainly engaged in the production of steel profiles and sales, but also set up a steel doors and windows factory, including products, there are insulating glass Building glass supporting sales.

- Q:Why does the endothermic glass be cool in winter and cool

- Summer architectural glass membrane can block up to 85% of the solar heat into the indoor UV blocking rate of not less than 99% and has good light transmission. Winter to prevent more than 50% of the indoor heat dissipation outflow, so that the indoor and outdoor temperatures are significantly different, Dongnuanxialiang, so that consumers save air conditioning or heating power consumption brought about by the high tariff.

- Q:GB / T16589 instead of which specification

- GB / T 28887-2017 Plastic window for construction is the first edition, so there is no substitute for other older versions. The specification refers to: GB / T 2680-1994 Building glass visible light transmittance, direct sunlight transmittance, solar total transmittance, UV transmittance and the determination of the relevant window parameters, GB / T 5823-2008 Building doors and windows terms, GB / T 7106-2008 Building exterior window windows airtight, watertight, wind pressure performance classification and testing methods, GB / T 8484-2008 building outside doors and windows insulation performance classification and testing methods, GB / T 8485-2008 building windows and doors air sound insulation (PVC-U) profiles, GB / T 11793-2008 Non-plasticized polyvinyl chloride (PVC-U) plastic doors and windows, mechanical properties, GB / T, And GB / T 11976-2002 GB / T 14436-1993 General rules for industrial product assurance documents, GB 50009 - 2001 (2006) JGJ / T 151-2008 Technical code for the application of architectural glass, JGJ / T 151-2008 Code for thermal calculation of glass curtain wall for building windows and doors, GB Building doors and windows.

- Q:Our community bedroom bay window with hollow glass color aluminum windows, finished less than 4 years of glass on the natural fragmentation. But the purchase contract on the renovation works only one year warranty, how long is the shelf life of insulating glass? If this is based on, can we ask developers to replace?

- Generally good manufacturers of insulating glass warranty period of 10 years. Your home glass broken to see what the situation, the general external collision, steel blew, overheating (sun or heating facilities) three cases. External force collision this manufacturer is impossible to lose. Overheating, then you should find the district property, this is the design of the problem. Steel blew words need to pay attention, and generally in the center of the blew will be similar to butterfly-like two small glass, we called "Hu Dieban", found that this can find manufacturers compensation.

- Q:There is a clear coat of build up o my glasses lense. Not sure what it is but I can feel it when I scrape it with my finger. Looks like something froze on it haha best way to describe it I guess ha. Was thinking acetone but dont want to mess up the lense. Any ideas?

- Are you sure it's not the scratch coat or the antireflective coating peeling off? If so, take them back to wear you got them and have them make a new pair of lenses. You may not have bought the glasses knowing that was on there as some lenses (most now) come with a scratch coat already on the lenses. From your description that is what it sounds like. Otherwise, try a Mr. Clean Eraser if Dawn and water have not worked. You could try acetone but you have to stand by with water to get it off right away or it could cloud the lenses too.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A variety of colors Glaze Reinforced Glass 6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ /month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords