A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

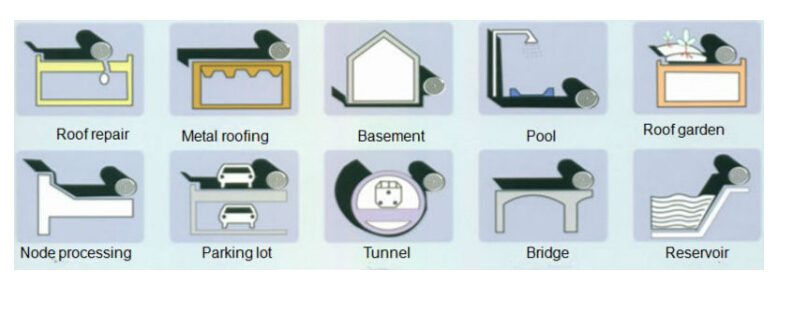

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

3. Product Application:

a. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

b. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

c. Application Method:

Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

d. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

4. Some photos:

- Q:Can a waterproofing membrane be used in swimming pools or other water features?

- Certainly, swimming pools or other water features can indeed utilize a waterproofing membrane. In fact, it is highly advisable to employ such a membrane in these areas to avert water leakage and potential harm. By serving as a barrier between the water and the surrounding structures, a waterproofing membrane ensures that the water remains contained within the pool or water feature. Not only does it prevent water seepage, which can inflict structural damage and necessitate expensive repairs, but it also safeguards the pool or water feature from the harsh chemicals employed for water treatment, thereby guaranteeing its durability and long lifespan. Consequently, the utilization of a waterproofing membrane is an essential measure in the construction or renovation of swimming pools or other water features, guaranteeing their functionality and longevity.

- Q:SBS Shale Waterproof Coil

- SBS modified asphalt waterproofing membrane, this coil has a good high temperature performance, can be -25 to +100 ℃ temperature range of use, a higher flexibility and fatigue resistance, and up to 1500% Elongation and strong puncture resistance, tear resistance. Suitable for cold areas, as well as deformation and vibration of large industrial and civil buildings waterproofing works.

- Q:Are waterproofing membranes resistant to earthquake movements?

- Waterproofing membranes serve the purpose of safeguarding structures, such as buildings and basements, from the invasion of water and moisture. While they effectively prevent water damage, they are not specifically engineered to withstand or endure the movements caused by earthquakes. Earthquakes involve the shaking and displacement of the ground, which exert considerable forces on structures. Waterproofing membranes do not typically possess the ability to absorb or distribute these forces in the same manner as seismic-resistant materials or building techniques. Nevertheless, it is important to note that certain waterproofing systems may exhibit a certain level of flexibility or elasticity, which could potentially offer some resistance against minor ground movements during an earthquake. These characteristics may assist in maintaining the integrity of the membrane and preventing water infiltration if slight shifting or settling occurs. Ultimately, when it comes to earthquake resistance, it is vital to employ specialized seismic design principles and techniques that are suitable for the specific location and building requirements. In order to ensure overall structural integrity and safety during seismic events, waterproofing membranes should be utilized in conjunction with these seismic-resistant measures.

- Q:The difference between high polymer modified asphalt waterproofing membrane and sbs

- High-polymer modified asphalt waterproofing membrane: synthetic polymer modified asphalt coating layer, fiber fabric or fiber mat for the carcass, powder, granular, sheet or film material made of cladding material can be curled Of the sheet material. Thickness is generally 3mm, 4mm, 5mm, asphalt as the main body.

- Q:Can a waterproofing membrane be used in temporary or temporary structures?

- Yes, a waterproofing membrane can be used in temporary or temporary structures. It provides an effective barrier against moisture, protecting the structure from potential water damage during its temporary lifespan.

- Q:SBs waterproof cold sticky how to do?

- 5, protective layer construction. In order to shield or reflect the sun's radiation, to extend the life of the waterproof layer of the membrane, in the waterproof layer is completed and checked after passing, should be coated on the surface of the waterproof layer of adhesive, side of the expansion of the expansion of silica powder protective layer, or uniform Brush the silver or green paint as a protective layer.

- Q:Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q:Can a waterproofing membrane be installed on metal surfaces?

- A waterproofing membrane is capable of being installed on metal surfaces, indeed. There exist various types of waterproofing membranes to choose from, with some specifically intended for metal substrates. These membranes are typically constructed using materials like PVC, TPO, or EPDM, which possess flexibility and a good adhesive quality to adhere well to metal surfaces. The installation process primarily involves cleaning and preparing the metal surface, and if required, applying a primer. Following this, the waterproofing membrane is applied using adhesive or heat welding techniques. This application creates a protective barrier against water infiltration, thereby preventing corrosion and damage to the metal surface. It is crucial to ensure that the chosen waterproofing membrane is compatible with the specific type of metal in use, and that proper installation procedures are followed to achieve effective waterproofing.

- Q:Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM roofs are typically made from a rubber material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, extending the lifespan of the roof.

- Q:Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can certainly be used on roofs with skylights. In fact, it is highly recommended to use a waterproofing membrane around skylights to prevent any water infiltration or leakage. Skylights are potential weak points in a roof system, as they create openings that can allow water to seep through if not properly sealed. By applying a waterproofing membrane around the skylights, it helps to create a watertight barrier that protects the roof from any potential leaks. Additionally, a waterproofing membrane can also provide added protection against other elements such as UV rays and temperature fluctuations, prolonging the lifespan of both the skylights and the roof itself.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords