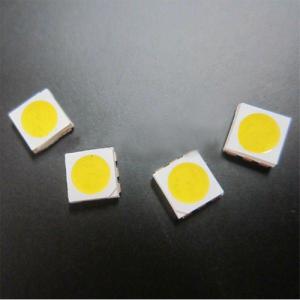

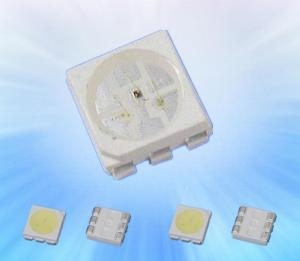

5050 SMD LED Chip, High Quality Epistar LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

5050 SMD LED Chip,High Quality Epistar LED Chip

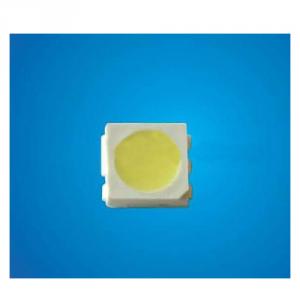

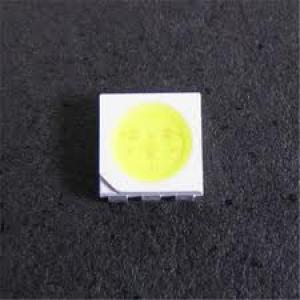

5.0mmx5.0mm SMD LED, 1.5mm Thickness

Specification

| Size | 5.0*5.0mm |

| Shapes | SMD |

| Emitting color | White |

| Beam Angle | 120 degree |

| C.C.T | 6,500K |

| Forward Voltage | 3.2-3.6V |

| Forward Current | 60mA |

| Lens colors | Yellow diffused |

| Life span | 50,000hours |

| Packing | 2000pcs/reel |

| Certificates | CE |

| Luminous Intensity | 5000-8000mcd |

Features and our advantages

1. Emitted Color: 5050 SMD LED white color

CCT : 3000-7000K

Luminous Flux: 15-23lm

Luminous intensity:5500~7000mcd @120 degrees

2. Led Appearance: Yellow diffuse with white face support

3. 5.0*5.0*1.5mm standard package

4. Suitable for all SMT assembly methods

5. Compatible with infrared and vapor phase reflow solder process

6. Compatible with automatic placement equipment

7. This product doesn’t contain restriction Substance, comply ROHS standard

8.Compatible with IR Reflow soldering and TTW soldering

9.Pb free product and acceptable lead-free process

10.Anti-electric and moisture free package(2K/Reel)

11.We have the ability to fulfill your customized orders

OEM&ODM available

Application

1.Indoor and out door commercial light

2.LED backlighting and SMD type indicator

3.LED midule and LED strip light

4.Decoration lights

Our Services

1-Customized logo is acceptable

2-Changing the shape, color is acceptable

3-Develop on artwork & development is acceptable

4-Assistant on artwork development is acceptable

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:Which is good for LED patch and LED bulb?

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q:What is patch LED?

- Patch element. Very small, no pins, soldered directly to the circuit board. For example, the keyboard lights in a mobile phone are used in this way.

- Q:What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Pin forming, 1, LED pin molding must be completed before welding, bending angle must be more than 3mm of the gel to bend the stent. Pin over 2 times in the same place can not fold number, pin bent to 90 degrees, and then returned to the original position for 1 times; 2, pin forming must use fixture or by professional personnel to complete the first, pay attention to avoid the epoxy body caused by excessive internal wire fracture; 3, to ensure the distance between pin pin forming consistent with the circuit board; 4, when LED has good welding in the welding process or after, please don't bend light feet, to avoid damage to the lamp.

- Q:What, in what way do I shunt the LED?

- In series, the voltage is 20 times the rated voltage, in parallel, the voltage is rated voltage, but in tandem, a LED is broken, it is not bright, so it is recommended not to use it.

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- The same, stick pieces is an early product, stick pieces than patch mature, stick pieces of my lamp has almost can not see what changes for three years with only a patch of brightness, years have been feeling a lot of dark. I believe the quality will be good soon.

- Q:SMD LED lamp working voltage?

- LED is a light emitting device of low voltage, low current, low power forward current general patch type LED when using (IF) 20MA, (VF) 1.8-2.5V, voltage of red green and blue (VF) voltage is 3.0-3.6V. Different manufacturers also have small differences, so first of all, look at the color,Of course. The multi chip assembly in high voltage chip together, some current: 1 watts, 1 watts and above. A wide variety of varieties, as follows:

- Q:How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- Because the LED open threshold is about 1.5-1.8V. It is possible that the voltage supplied by the digital multimeter does not activate it. So look at the sign. Patch LED (SMD LED), the green point of negative, relative to the positive.

- Q:What determines the brightness of the patch LED?

- Lamp brightness level itself, is also in the rated current situation, its brightness

- Q:LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- SMD patch products basically can be used in reflow soldering, especially a little note here that the eutectic welding is the connection between the chip and the substrate support or specifically, is the bottom of the chip after completion of production of coating material and a layer of Sikkim alloy, and then set up a heating zone in solid crystal machine package in time and a temperature of about 300 degrees, the realization process of the chip at the bottom of the Sikkim alloy melt and silver plated layer connection bracket, and a clear distinction between reflow.

- Q:What does patch LED light mean?

- Look, what's your product?. Some products have volume requirements, straight line will be relatively large, patches of small affixed to the circuit board does not occupy space, if only the light source, it may be an ordinary light bulb, as LED power saving.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5050 SMD LED Chip, High Quality Epistar LED Chip

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50000 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords