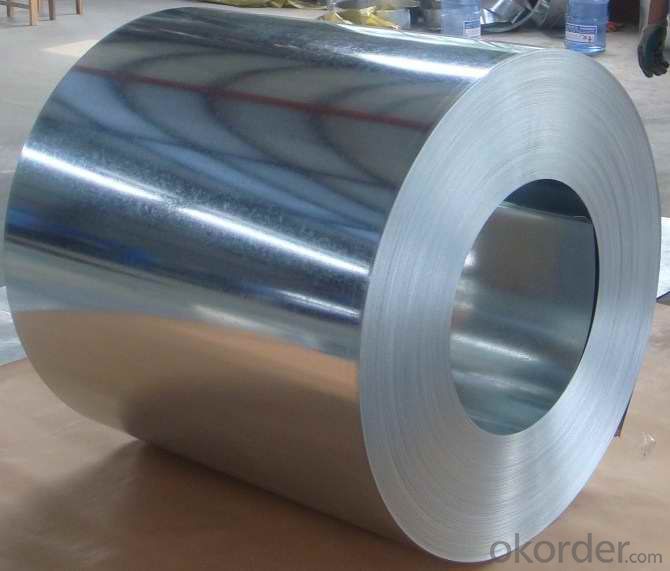

304 Stainless Steel Price per kg, 304 316 Stainless Steel Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

304 Stainless Steel Price per kg, 304 316 Stainless Steel Sheet and Coil

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

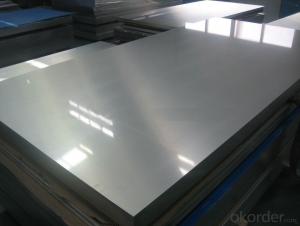

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q:What are the limitations of using stainless steel sheets?

- Some limitations of using stainless steel sheets include their high initial cost, susceptibility to scratching, potential for corrosion in certain environments, and difficulty in shaping complex designs. Additionally, stainless steel sheets are relatively heavy, which can be a disadvantage in certain applications where weight is a concern.

- Q:Can stainless steel sheets be used for elevator handrails or grab bars?

- Yes, stainless steel sheets can be used for elevator handrails or grab bars. Stainless steel is a popular choice for these applications due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be fabricated into various shapes and sizes to meet the specific requirements of elevator handrails or grab bars, ensuring safety and comfort for users. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for high-traffic areas such as elevators.

- Q:What are the different types of stainless steel sheet grades available?

- There exists a range of stainless steel sheet grades, each possessing distinctive properties and applications. The following are some commonly used stainless steel sheet grades: 1. Austenitic stainless steel, such as 304 and 316, is widely utilized due to its outstanding corrosion resistance and high ductility. It lacks magnetic properties and can be easily formed and welded. 2. Ferritic stainless steel, including 430 and 409, exhibits magnetic properties and excellent corrosion resistance, particularly in high-temperature environments. Although less ductile than austenitic stainless steel, it offers good strength and formability. 3. Martensitic stainless steel, like 410 and 420, is characterized by its high strength, hardness, and wear resistance. It is commonly employed in applications where toughness and corrosion resistance are of lesser importance. 4. Duplex stainless steel, such as 2205 and 2507, is a combination of austenitic and ferritic stainless steels. It provides a unique blend of strength, corrosion resistance, and cost-effectiveness. This type is highly resistant to stress corrosion cracking and finds application in industries such as oil and gas, chemical processing, and marine applications. 5. Precipitation hardening stainless steel, represented by grades like 17-4 PH and 15-5 PH, is heat-treatable and offers high strength and corrosion resistance. It is commonly employed in aerospace and high-performance applications that necessitate a combination of strength and corrosion resistance. These are merely a few examples of the diverse stainless steel sheet grades available. Each grade possesses specific characteristics and is chosen based on desired properties and intended applications.

- Q:What's the difference between galvanized steel and stainless steel?

- Galvanized steel sheet is to prevent the corrosion of steel plate surface, and prolong its service life, the surface of the steel plate is coated with a layer of metal zinc, this kind of zinc coated steel sheet is called galvanized sheet.

- Q:How do you remove stains or marks from stainless steel sheets?

- To remove stains or marks from stainless steel sheets, you can start by wiping the surface with a soft cloth or sponge dipped in a mixture of warm water and mild dish soap. Gently scrub the affected area in the direction of the grain, then rinse with clean water and dry thoroughly. For tougher stains, you can apply a paste of baking soda and water, leave it on for a few minutes, and then scrub gently before rinsing and drying. Avoid using abrasive cleaners or scrub brushes that can scratch the stainless steel surface.

- Q:How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q:What's the difference between cold rolled plate and stainless steel?

- Cold rolled steel plates will soon rust (in the wind and rain). Rust must be painted outsideAs the price of chromium and nickel is very high, the price of stainless steel plate is several times that of ordinary cold-rolled steel sheet

- Q:What are the different types of perforated patterns available for stainless steel sheets?

- Stainless steel sheets come in a variety of perforated patterns, each serving specific purposes and meeting different aesthetic preferences. Let's explore some commonly used patterns: 1. The round hole pattern is the most widely used and basic design. It consists of evenly spaced round holes that allow for excellent airflow and drainage. It finds its applications in industrial filtration systems or as decorative panels. 2. The square hole pattern, similar to the round hole pattern, offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, providing a modern and sleek look. 3. The slotted hole pattern consists of elongated and rectangular holes, allowing for more flexibility in terms of airflow and visibility. It is commonly used in grills or air ventilation systems where better drainage or a higher open area is required. 4. The hexagonal hole pattern offers a unique and visually appealing design. It provides excellent strength and structural integrity, making it suitable for applications requiring durability, such as safety barriers or machine guards. 5. In addition to the standard patterns, there are various decorative hole patterns available for stainless steel sheets. These patterns feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. When selecting a perforated pattern for stainless steel sheets, it is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

- Q:Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q:Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance, durability, and high strength, making it suitable for various filtration processes. It can effectively filter out particles, contaminants, and impurities in liquids and gases, making it a popular choice for industries such as food and beverage, pharmaceutical, chemical, and wastewater treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Price per kg, 304 316 Stainless Steel Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords