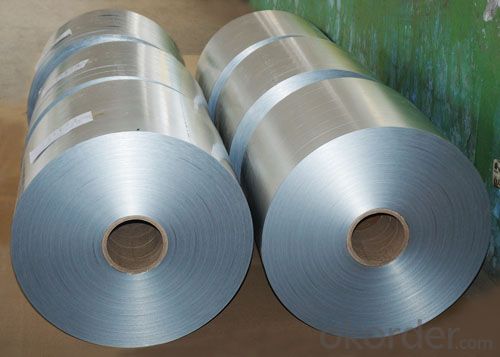

1100 1200 O H14 H24 Mill Finish Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1100 1200 O H14 H24 Mill Finish Aluminium Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q:Can aluminum coils be recycled multiple times?

- Yes, aluminum coils can be recycled multiple times. Aluminum is a highly recyclable material, and the recycling process for aluminum coils involves melting them down to create new coils. This means that aluminum coils can be recycled indefinitely without losing their properties or quality.

- Q:How are aluminum coils used in solar panels?

- Aluminum coils are used in solar panels as part of the construction and structure of the panel. They are used to hold the solar cells in place and provide a sturdy framework for the overall structure. Additionally, aluminum coils help with heat dissipation and ensure efficient functioning of the solar panel by preventing warping or damage caused by temperature fluctuations.

- Q:Can aluminum coils be used for structural purposes?

- Yes, aluminum coils can be used for structural purposes. Aluminum is a lightweight and versatile material that offers excellent strength-to-weight ratio. It is commonly used in various structural applications, including the construction of buildings, bridges, and aircraft. Aluminum coils can be formed and shaped into different profiles to provide support and stability in structural systems. Additionally, aluminum is highly corrosion-resistant, which makes it suitable for outdoor and marine environments. However, it is important to consider the specific requirements and load capacities of the structural project to determine if aluminum coils are suitable for the intended purpose.

- Q:Are aluminum coils suitable for signage systems?

- Indeed, signage systems find aluminum coils to be a fitting choice. The durability, versatility, and lightweight nature of aluminum render it a popular material option for signage. Its resistance to corrosion makes it apt for outdoor signage that endures diverse weather conditions. Aluminum coils possess the ease of being molded into different shapes and sizes, enabling flexibility in design. Moreover, aluminum can be painted or coated to attain various finishes and colors, thus granting high customizability and visual allure in signage applications. Ultimately, the utilization of aluminum coils in signage systems guarantees a durable, low-maintenance, and visually pleasing solution.

- Q:Why do we need aluminum when cooking in the oven at all.

- Aluminum foil is an incredibly versatile cooking product as it can take the heat of almost any kind of cooking (stove, oven, grill, firepit), it can be formed into any shape needed. It also retains the juices in the roast while baking, so as to cook completely without burning. Keeps the direct heat off your roast. Catches spillovers from pies, casseroles, stews etc.

- Q:Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a commonly used material due to its lightweight, conductivity, and corrosion resistance properties. It is often used in electronic devices such as capacitors, inductors, and transformers.

- Q:How do aluminum coils resist corrosion?

- Aluminum coils are able to resist corrosion due to their unique chemical composition and protective oxide layer. Aluminum is a highly reactive metal, but it forms a thin layer of aluminum oxide on its surface when exposed to air. This oxide layer acts as a protective barrier, preventing further reaction with the environment. This layer is self-repairing and continues to form even when it gets damaged, providing long-lasting protection against corrosion. Additionally, aluminum coils can be further protected by applying coatings or treatments that enhance their resistance to corrosion. These coatings act as an additional layer of defense, shielding the coils from potential corrosive agents. Overall, the combination of the natural oxide layer and optional coatings makes aluminum coils highly resistant to corrosion, ensuring their durability and longevity in various applications.

- Q:What are the effects of casting temperature on ductility of aluminum coil?

- The tensile strength and ductility increase with the solid solution insulation time, and reach best fit at 1 hour. Continue thermal insulation, and the tensile strength will change little while the ductility will reduce. This is because the solid solution over insulation will cause the work pieces crystallize so that the large crystal reduce the plasticity.

- Q:Can aluminum coils be used for heat recovery systems?

- Yes, aluminum coils can be used for heat recovery systems. Aluminum is a highly conductive material, which makes it an excellent choice for transferring heat. Aluminum coils are often used in heat exchangers and heat recovery systems to efficiently transfer heat from one medium to another. These coils are designed to maximize surface area, allowing for greater heat transfer. Additionally, aluminum is lightweight and corrosion-resistant, making it durable and suitable for various applications in heat recovery systems.

- Q:Which aluminum roll is good?

- Complete product specifications, quality assurance, brand strength has very good cutting characteristics of Gaoyang welding, the main products are pure aluminum, aluminum alloy, aluminum pattern, Japan Sumitomo mirror aluminum, aluminum and other materials imported from South Korea, widely used in home appliance industry, stamping, sheet metal production, decoration, curtain wall, automobile industry, mold processing. Ship manufacturing, pipe insulation, lighting, advertising signs, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100 1200 O H14 H24 Mill Finish Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords