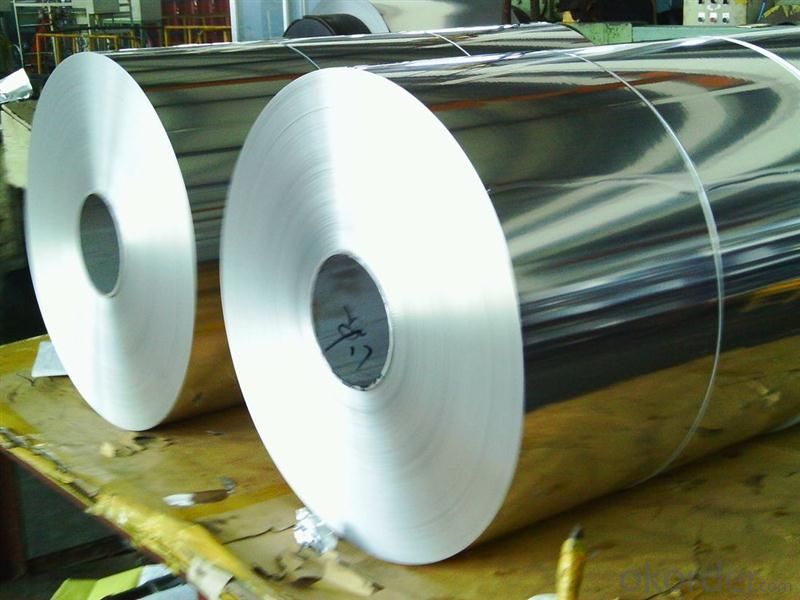

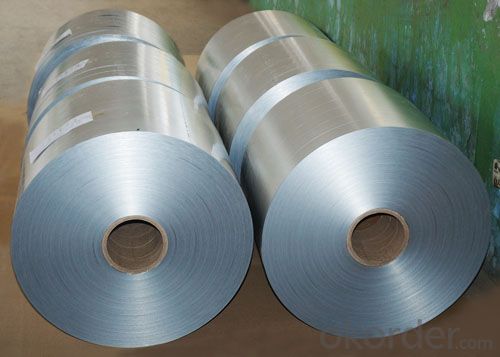

1050 1060 O H14 H24 Mirror Insulation Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1050 1060 O H14 H24 Mirror Insulation Aluminium Coil

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q:Can aluminum coils be used in the production of air conditioning systems?

- Indeed, air conditioning systems can utilize aluminum coils. The reason behind the widespread usage of aluminum coils in air conditioning systems lies in their remarkable heat transfer properties and ability to resist corrosion. Not only are they lightweight and long-lasting, but they also exhibit high efficiency when it comes to transferring heat between the refrigerant and the air. Moreover, aluminum coils outshine traditional copper coils in terms of environmental friendliness, as they necessitate less energy during the manufacturing process and can be completely recycled. All in all, the performance, durability, and eco-friendliness of aluminum coils make them a favored option for air conditioning systems.

- Q:What’s the difference between aluminum tile, coil and sheet? Why?

- Wood pallet is often used, which is easy to transport and can ensure the safety of products.

- Q:What are the standard dimensions for aluminum coils?

- The standard dimensions for aluminum coils can vary depending on the specific application and industry. However, there are some commonly accepted standard dimensions for aluminum coils. In terms of width, aluminum coils typically range from as narrow as 4 inches (10 cm) to as wide as 60 inches (152 cm). The exact width can be determined by factors such as the intended use, manufacturing process, and customer specifications. Regarding thickness, aluminum coils are available in a range of thicknesses, typically measured in gauge or millimeters. Common thicknesses for aluminum coils can range from 0.018 inches (0.46 mm) to 0.25 inches (6.35 mm) or even thicker in certain applications. The length of aluminum coils can also vary, depending on the specific requirements of the customer or the industry. Coils can be supplied in standard lengths, such as 1000 feet (304.8 meters) or 2000 feet (609.6 meters), or they can be custom cut to a desired length. It is important to note that these dimensions are not fixed and can be customized based on the specific needs of a particular project. Industries that commonly use aluminum coils, such as construction, automotive, and aerospace, may have their own unique size requirements. Therefore, it is always recommended to consult with an aluminum coil manufacturer or supplier to determine the most suitable dimensions for a specific application or project.

- Q:What is the typical electrical resistivity of aluminum coils?

- The typical electrical resistivity of aluminum coils is around 2.65 x 10^-8 ohm-meters.

- Q:How do aluminum coils compare to titanium coils in terms of weight?

- Aluminum coils are significantly lighter in weight compared to titanium coils. Aluminum has a lower density than titanium, which means that the same volume of aluminum weighs less than titanium. This characteristic makes aluminum coils a preferred choice in various industries where weight reduction is crucial, such as aerospace and automotive applications. Titanium coils, on the other hand, are known for their exceptional strength and high corrosion resistance, making them suitable for environments where durability is a priority. Ultimately, the choice between aluminum and titanium coils depends on the specific requirements and trade-offs desired for a particular application.

- Q:What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q:Can aluminum coils be used in food packaging?

- Indeed, food packaging can make use of aluminum coils. Aluminum, a secure and adaptable substance, has enjoyed extensive usage in the food packaging sector for numerous years. It provides numerous advantages, including its lightweight nature, resistance to corrosion, and exceptional thermal conductivity. These qualities render it perfect for food packaging scenarios that prioritize the maintenance of food product quality, freshness, and safety. Aluminum coils can be conveniently molded into various shapes and dimensions, permitting tailored packaging solutions. Furthermore, aluminum qualifies as a sustainable material due to its 100% recyclability, further augmenting its allure for food packaging purposes.

- Q:I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q:Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q:Can aluminum coils be used in high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and tend to lose their structural integrity at elevated temperatures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1050 1060 O H14 H24 Mirror Insulation Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords