1.5mm 4X8 Corten A Steel Plate in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Corten A Steel Plate

1.Specification and Application:

Specification: Corten A is a weather resistant steel created by alloying copper, chromium and nickel.

Corten A has added phosphorous which makes the material best suited for gas flue applications and for aesthetic facias. The material is not recommended in heavy load bearing applications – in this case Corten B or S355J2W should be considered.

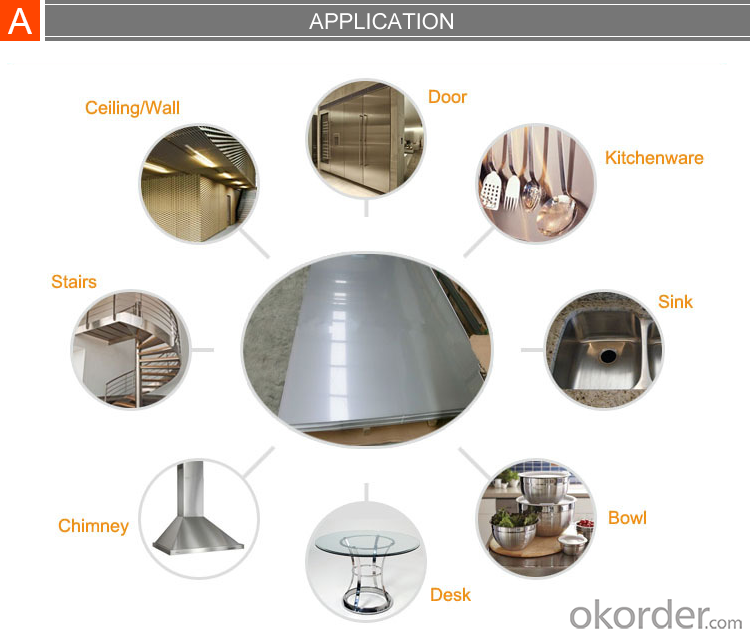

Application: The steel is used for various types of welded, bolted and riveted constructions e.g. steel frame structures, bridges, tanks and containers, exhaust systems, vehicles and equipment constructions

2. Steel Grade :

Corten A

3. The dimension:

Thickness: 6mm to 300mm,

Width: 1500mm to 4050mm,

Length: 3000mm to 15000mm

4. Chemical composition: The Chemical is max composition of product analysis:

Grade | C | Si | Mn | P | S |

Corten A | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07-0.15 | 0.030 |

Carbon Equivalent: Ceq = [C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15]%

5. Mechanical properties at ambient temperature:

Grade | Thickness | Yield | Tensile | Elongation |

Corten A | mm | Min Mpa | Mpa | Min % |

6-12 | 345 | 485 | 20 |

6. Certificates:

Our steel plates have been certified by TUV, SGS, CE and nine Classification Societies: ABS, DNV, LR, GL, BV, KR, RINA, CCS, NK. Each plate has the Mill Certificate Test EN 10204 3.1/3.2 Version.

7. Equivalent steel grade of Corten A:

Europe | UNI | Germany | France | UK | Sweden | India | Japan |

S355J0WP | Fe510 C1K1 | E 36WA3 | WR50A |

Our Advantage

a. Professinal international trade experience in steel product field.

b. Strict with quality control, to make every steel pipe perfect.

c. For more detail information please contact us.

- Q:How do you remove heat discoloration from stainless steel sheets?

- To remove heat discoloration from stainless steel sheets, there are a few different methods you can try. One common method is to use a stainless steel cleaner or polish specifically designed to remove heat discoloration. These products often contain mild abrasives that can help to remove the discolored layer. Follow the instructions on the product and apply it to the affected area using a soft cloth or sponge. Rub gently in a circular motion, then rinse with water and dry thoroughly. Another method involves using a mixture of baking soda and water. Create a paste by mixing equal parts baking soda and water. Apply the paste to the discolored area and gently rub it in using a soft cloth. Rinse with water and dry thoroughly. If the discoloration is stubborn and the above methods haven't worked, you can try using a stainless steel scratch eraser or a fine-grit sandpaper. Be cautious when using these methods as they can potentially scratch the stainless steel surface. Always test in a small inconspicuous area first and proceed with caution. It's important to note that prevention is key in avoiding heat discoloration on stainless steel sheets. Using heat-resistant pads or trivets under hot pots and pans can help prevent heat transfer to the stainless steel surface. Additionally, avoiding direct contact with high heat sources, such as placing stainless steel sheets too close to stovetops or ovens, can also prevent discoloration.

- Q:What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets can vary depending on the specific alloy and processing conditions. Generally, stainless steel is considered to have a low magnetic permeability, making it a poor conductor of magnetic fields. However, some types of stainless steel, such as ferritic stainless steel, have a higher magnetic permeability compared to other grades like austenitic stainless steel. It is important to note that the magnetic permeability of stainless steel can also be affected by factors such as temperature and the presence of external magnetic fields. Therefore, it is best to consult specific technical data or perform magnetic permeability testing for accurate and detailed information about the magnetic properties of stainless steel sheets.

- Q:Can stainless steel sheets be used for heat recovery systems?

- Yes, stainless steel sheets can be used for heat recovery systems. Stainless steel is known for its excellent heat resistance and durability, making it an ideal material choice for heat recovery applications. Its corrosion resistance and ability to withstand high temperatures make it suitable for capturing and transferring heat efficiently in various heat recovery systems.

- Q:What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets are utilized in numerous industries and applications due to their wide range of standard sizes and thicknesses. Typically, the standard sizes vary from 4 feet by 8 feet to 5 feet by 10 feet, but customized sizes can also be obtained based on specific needs. In terms of thickness, stainless steel sheets are offered in various standard options. These include 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). It is important to note that these thicknesses indicate the nominal thickness, and the actual thickness may have slight variations. Additionally, it is worth noting that stainless steel sheets are also available in metric sizes. Common thicknesses in metric sizes range from 0.5 mm to 3 mm. This provides flexibility and compatibility with international standards and specifications. In summary, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements. This ensures their widespread availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q:Are stainless steel sheets good for exhaust systems?

- Yes, stainless steel sheets are excellent for exhaust systems. Stainless steel is a popular choice for exhaust system materials due to its high resistance to corrosion, heat, and pressure. It can withstand the extreme temperatures and harsh conditions that exhaust systems are exposed to, ensuring durability and longevity. Stainless steel also has excellent acoustic properties, helping to reduce noise levels. Additionally, stainless steel sheets can be easily formed and welded, allowing for the creation of customized exhaust system designs. Overall, stainless steel sheets are a reliable and efficient material for exhaust systems in terms of performance, aesthetics, and overall functionality.

- Q:Can stainless steel sheets be used for lighting fixtures?

- Indeed, lighting fixtures can utilize stainless steel sheets. Stainless steel, a material renowned for its versatility and durability, finds wide application in numerous fields, including lighting fixtures. It boasts various advantages, such as resistance to corrosion, remarkable strength, and aesthetic allure. By employing stainless steel sheets, one can effortlessly mold, fabricate, and weld them to generate diverse lighting fixture designs and finishes. Furthermore, stainless steel's reflective surface heightens the lighting effect, ultimately creating an eye-catching and brilliantly illuminated atmosphere. Hence, due to their lastingness, adaptability, and aesthetic attributes, stainless steel sheets prove to be a fitting choice for lighting fixtures.

- Q:What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can differ depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability in comparison to carbon steel or aluminum. This is primarily because of its higher strength, hardness, and work-hardening characteristics. During machining, stainless steel tends to work-harden, resulting in increased cutting forces and tool wear. It also has lower thermal conductivity, which can lead to higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and hard-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to enhance the machinability of stainless steel. For example, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can display varying levels of machinability. Austenitic stainless steels, such as 304 and 316, are generally more challenging to machine compared to ferritic or martensitic stainless steels. This is because of their higher nickel and chromium content, which contribute to their excellent corrosion resistance but also make them harder to machine. Overall, although machining stainless steel sheets may present some difficulties, with the right tools, techniques, and expertise, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

- Q:Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs.

- Q:How do you prevent discoloration on stainless steel sheets?

- There are several steps you can take to prevent discoloration on stainless steel sheets. Firstly, it is essential to clean the surface regularly. Use mild soap or detergent with warm water and avoid abrasive cleaners or scrubbing pads that can cause scratches. Secondly, avoid using harsh chemicals or cleaners that contain chlorine, bleach, ammonia, or acids. Stick to mild and non-abrasive cleaners specifically made for stainless steel. After cleaning, make sure to rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Residual chemicals can cause discoloration if left on the surface for too long. It is important to dry the stainless steel sheet completely after cleaning and rinsing. Moisture left on the surface can lead to water spots or staining, especially in areas with hard water. Use a soft cloth or towel to remove all moisture and ensure a dry and shiny surface. Applying protective coatings or sealants designed for stainless steel can help prevent discoloration. These coatings create a barrier that protects the surface from environmental factors like humidity, oxidation, and staining. Proper handling and care are also crucial. Avoid dragging or sliding objects across the sheets to prevent scratches or abrasions that may lead to discoloration. Handle the sheets with care, using clean gloves or a soft cloth to minimize the risk of surface damage. Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly by following the appropriate cleaning and maintenance procedures to prevent further damage and maintain the appearance of the stainless steel. By following these preventive measures, you can effectively minimize discoloration on stainless steel sheets and keep them looking clean, shiny, and free from stains for a longer period of time.

- Q:Can stainless steel sheets be used for countertops?

- Certainly! Countertops can indeed be made using stainless steel sheets. Stainless steel is a material known for its durability and versatility, as it possesses resistance against stains, heat, and bacteria. Consequently, it proves to be an exceptional option for kitchen countertops. Moreover, stainless steel countertops are effortless to clean and maintain, all while presenting a sleek and contemporary look. While commonly found in commercial kitchens, these countertops are steadily gaining popularity in residential settings, owing to their durable nature and hygienic qualities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.5mm 4X8 Corten A Steel Plate in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords