All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

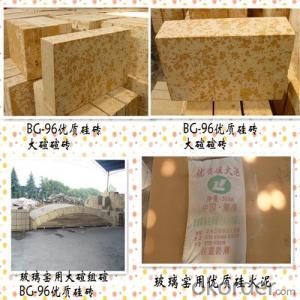

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks perform in cryogenic conditions?

Refractory bricks perform well in cryogenic conditions due to their ability to withstand extremely low temperatures without losing their structural integrity or thermal insulation properties. The high-density materials used in refractory bricks have low thermal conductivity, preventing heat transfer and maintaining the cold temperature within the cryogenic environment. Additionally, refractory bricks have excellent resistance to thermal shock and chemical corrosion, making them ideal for applications in cryogenic industries such as liquefied natural gas (LNG) storage tanks or liquid nitrogen storage vessels.

Can refractory bricks be used for thermal oxidizers?

Yes, refractory bricks can be used for thermal oxidizers. Refractory bricks are designed to withstand high temperatures and are commonly used in industrial applications, including thermal oxidizers, which require heat resistance and insulation properties.

How are refractory bricks tested for quality?

Refractory bricks are tested for quality through various methods such as visual inspection, physical and chemical analysis, and performance testing. Visual inspection involves checking for any defects, cracks, or irregularities in the bricks. Physical analysis includes measuring dimensions, density, porosity, and strength to ensure they meet the required specifications. Chemical analysis is conducted to determine the composition and purity of the bricks, ensuring they have the desired chemical properties. Performance testing involves subjecting the bricks to extreme temperatures, thermal shocks, and mechanical stress to assess their resistance and durability. These comprehensive tests ensure that refractory bricks meet the stringent quality standards before being used in high-temperature applications.

Wholesale Refractory Bricks from supplier in Uruguay

Whether you are in need of Refractory Bricks for industrial furnaces, kilns, or any other high-temperature applications, our team can assist you in finding the right products to meet your specific requirements. We understand the unique challenges and demands of the Uruguayan market and can provide customized solutions to ensure optimal performance and longevity of your refractory materials.

Our sales team is committed to delivering excellent customer service and will work closely with you to understand your needs and provide competitive pricing and timely quotations. We also offer technical support, including guidance on product selection, installation, and maintenance, to ensure the best results for your projects.

As a subsidiary of CNBM, we have access to a vast network of reliable suppliers and manufacturers, allowing us to offer a wide range of high-quality refractory products at competitive prices. Our efficient procurement process ensures timely delivery of your orders, minimizing downtime and maximizing productivity.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships. We are dedicated to delivering superior products and services that meet the highest industry standards. Trust us to be your reliable partner for all your refractory brick needs in Uruguay.

Our sales team is committed to delivering excellent customer service and will work closely with you to understand your needs and provide competitive pricing and timely quotations. We also offer technical support, including guidance on product selection, installation, and maintenance, to ensure the best results for your projects.

As a subsidiary of CNBM, we have access to a vast network of reliable suppliers and manufacturers, allowing us to offer a wide range of high-quality refractory products at competitive prices. Our efficient procurement process ensures timely delivery of your orders, minimizing downtime and maximizing productivity.

At our company, we prioritize customer satisfaction and strive to build long-term partnerships. We are dedicated to delivering superior products and services that meet the highest industry standards. Trust us to be your reliable partner for all your refractory brick needs in Uruguay.

Hot Search

- Monolithic Refractories in British

- Ceramic Fiber Products in Niue

- Refractory Bricks in Germany

- Raw Materials For Refractory in Tuvalu

- Raw Materials For Refractory in Turkey

- Raw Materials For Refractory in Albania

- Monolithic Refractories in Madagascar

- Refractory Bricks in Senegal

- Raw Materials For Refractory in Philippines

- Ceramic Fiber Products in Maldives