All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

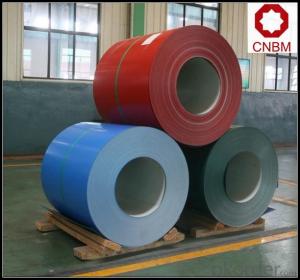

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations for selecting the proper aluminum coil thickness?

When selecting the proper aluminum coil thickness, some considerations to keep in mind include the intended application, structural requirements, desired strength and durability, weight restrictions, and cost-effectiveness. The thickness should be compatible with the specific project's needs and performance expectations to ensure optimal functionality and longevity.

What are the different types of coatings applied to aluminum coils for specific purposes?

There are several types of coatings applied to aluminum coils for specific purposes. These include polyester coatings, fluoropolymer coatings, polyvinylidene fluoride (PVDF) coatings, epoxy coatings, and acrylic coatings. Each type of coating offers unique properties such as weather resistance, corrosion resistance, durability, and aesthetic appeal, making them suitable for various applications such as building exteriors, automotive parts, and electronics.

How are aluminum coils treated to enhance their fire resistance properties?

Aluminum coils are treated using various techniques to enhance their fire resistance properties. One common method is the application of a thin layer of an intumescent coating. This coating reacts when exposed to heat, forming a protective char layer that insulates the aluminum and delays the spread of fire. Additionally, aluminum coils can be treated with flame-retardant additives during the manufacturing process, which impede the ignition and combustion of the material. These treatments enhance the fire resistance properties of aluminum coils, making them more suitable for applications where fire safety is a concern.

What is the weight of a standard aluminum coil?

The weight of a standard aluminum coil can vary depending on its size and thickness. However, on average, a standard aluminum coil typically weighs around 1-2 tons.

Wholesale Aluminum Coils from supplier in Uruguay

From small-scale projects to large industrial applications, our Aluminum Coils are designed to meet the highest standards of quality and performance. We offer a wide range of alloys, thicknesses, and finishes to suit your specific requirements.

Our team of experts is dedicated to providing exceptional customer service, from assisting you with product selection to offering technical advice and support. We understand the importance of timely delivery, and our efficient logistics network ensures that your orders are delivered on time, every time.

As a subsidiary of CNBM, we have access to a global network of resources and expertise, allowing us to offer competitive pricing and superior product quality. Our commitment to sustainability and environmental responsibility is reflected in our manufacturing processes, ensuring that our Aluminum Coils are not only reliable but also eco-friendly.

Whether you are in the construction, automotive, or packaging industry, we have the right Aluminum Coil solution for you. Contact us today to discuss your requirements and experience the convenience and efficiency of our one-stop procurement solutions.

Our team of experts is dedicated to providing exceptional customer service, from assisting you with product selection to offering technical advice and support. We understand the importance of timely delivery, and our efficient logistics network ensures that your orders are delivered on time, every time.

As a subsidiary of CNBM, we have access to a global network of resources and expertise, allowing us to offer competitive pricing and superior product quality. Our commitment to sustainability and environmental responsibility is reflected in our manufacturing processes, ensuring that our Aluminum Coils are not only reliable but also eco-friendly.

Whether you are in the construction, automotive, or packaging industry, we have the right Aluminum Coil solution for you. Contact us today to discuss your requirements and experience the convenience and efficiency of our one-stop procurement solutions.