All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main factors that affect the corrosion resistance of electrolytic tinplate coil?

The main factors that affect the corrosion resistance of electrolytic tinplate coil include the composition and thickness of the tin coating, the quality and cleanliness of the steel substrate, the presence of any impurities or defects in the tin coating or steel substrate, the pH level and composition of the surrounding environment, and exposure to moisture and humidity.

How does electrolytic tinplate coil perform in terms of weather resistance?

Electrolytic tinplate coil performs well in terms of weather resistance. The tin coating on the surface acts as a protective layer, preventing the underlying steel from oxidizing and rusting. This makes it highly resistant to moisture, humidity, and other weather conditions, ensuring its durability and longevity even in harsh outdoor environments.

What are the potential factors that can cause tinplate coil to exhibit poor resistance to poor weldability?

There are several potential factors that can cause tinplate coil to exhibit poor resistance to weldability. These factors can include the presence of impurities in the tin coating, inadequate surface preparation or cleaning before welding, improper welding techniques or parameters, and variations in the composition or thickness of the tin coating. Additionally, the presence of contaminants or foreign substances on the surface of the tinplate coil can also affect its weldability.

Can electrolytic tinplate coil be used in the production of metal aerosol cans?

Yes, electrolytic tinplate coil can be used in the production of metal aerosol cans.

What are the common coil weights available?

The common coil weights available vary depending on the specific industry and application. However, some common coil weights include 500 pounds, 1000 pounds, and 2000 pounds.

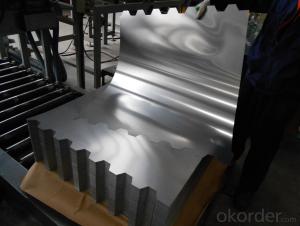

Wholesale Electrolytic Tinplate Coil from supplier in Timor Leste

Our Electrolytic Tinplate Coils are manufactured using advanced technology and adhere to international quality standards. They are highly durable, corrosion-resistant, and suitable for various applications such as packaging, canning, and automotive parts.

In addition to supplying Electrolytic Tinplate Coils, we also offer a range of services to support your procurement process. This includes product customization, logistics management, and technical support. Our team of experts will work closely with you to understand your specific requirements and provide tailored solutions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer competitive prices, reliable delivery, and efficient customer service. We strive to build long-term relationships with our clients and are committed to exceeding your expectations.

Contact us today to discuss your Electrolytic Tinplate Coil needs in Timor Leste. We look forward to partnering with you and contributing to the success of your projects.

In addition to supplying Electrolytic Tinplate Coils, we also offer a range of services to support your procurement process. This includes product customization, logistics management, and technical support. Our team of experts will work closely with you to understand your specific requirements and provide tailored solutions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to offer competitive prices, reliable delivery, and efficient customer service. We strive to build long-term relationships with our clients and are committed to exceeding your expectations.

Contact us today to discuss your Electrolytic Tinplate Coil needs in Timor Leste. We look forward to partnering with you and contributing to the success of your projects.