All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

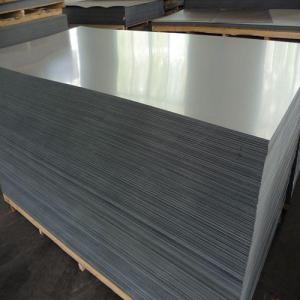

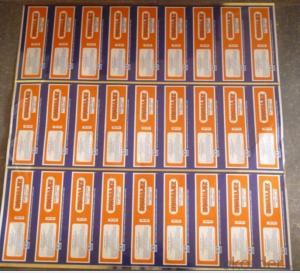

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is the surface finish of electrolytic tinplate coil achieved?

The surface finish of electrolytic tinplate coil is achieved through a multi-step process. Firstly, the tinplate coil undergoes a thorough cleaning and degreasing process to remove any impurities or contaminants. Next, the coil is immersed in an electrolyte solution, and an electrical current is passed through it. This electrolytic process causes tin ions from the solution to deposit onto the surface of the coil, resulting in a smooth and uniform layer of tin. Finally, the tin-coated coil is rinsed, dried, and further treated if necessary, to achieve the desired surface finish such as matte, bright, or stone.

What are the potential health risks associated with electrolytic tinplate coil?

The potential health risks associated with electrolytic tinplate coil are primarily related to the presence of tin and other metals in the coating. Prolonged exposure to high levels of tin can lead to respiratory issues, such as tin fume fever. Additionally, if the coating is damaged or corroded, there is a risk of metal contamination in food or beverages stored in the tinplate, which can pose further health concerns. It is important to handle and store electrolytic tinplate coil properly to minimize any potential health risks.

What is the typical width and length of an electrolytic tinplate coil?

The typical width and length of an electrolytic tinplate coil can vary depending on the manufacturer and specific requirements, but commonly, the width ranges from 600mm to 1,250mm, and the length can be anywhere from 500m to 2,000m.

Can electrolytic tinplate coil be used in the automotive industry?

Yes, electrolytic tinplate coil can be used in the automotive industry. It is commonly used for manufacturing various car parts such as body panels, fuel tanks, and engine components due to its high corrosion resistance, strength, and formability. Additionally, the tin coating on the surface provides added protection against oxidation and enhances the appearance of the final product.

Wholesale Electrolytic Tinplate Coil from supplier in Sri Lanka

Whether you require Electrolytic Tinplate Coils for packaging, can manufacturing, or any other application, we have you covered. Our high-quality products are sourced from trusted manufacturers and are known for their durability, corrosion resistance, and excellent formability.

In addition to our product range, we also offer competitive pricing and flexible delivery options to meet your specific requirements. Our dedicated sales team is always ready to provide you with personalized quotations and assist you in selecting the right product for your needs.

Furthermore, our technical support team is available to answer any questions you may have regarding the specifications, applications, or usage of our Electrolytic Tinplate Coil products. We understand the importance of technical guidance and are committed to ensuring that you have all the necessary information to make informed decisions.

As a subsidiary platform of CNBM, a global leader in building materials and equipment, we have access to a vast network of suppliers and resources. This allows us to consistently deliver high-quality products and services to our customers in Sri Lanka.

Whether you are a small business or a large corporation, we are dedicated to providing you with a seamless procurement experience. Our team is committed to building long-term relationships based on trust, reliability, and customer satisfaction.

Contact us today to discuss your requirements for Electrolytic Tinplate Coils in Sri Lanka. We look forward to partnering with you and contributing to the success of your projects.

In addition to our product range, we also offer competitive pricing and flexible delivery options to meet your specific requirements. Our dedicated sales team is always ready to provide you with personalized quotations and assist you in selecting the right product for your needs.

Furthermore, our technical support team is available to answer any questions you may have regarding the specifications, applications, or usage of our Electrolytic Tinplate Coil products. We understand the importance of technical guidance and are committed to ensuring that you have all the necessary information to make informed decisions.

As a subsidiary platform of CNBM, a global leader in building materials and equipment, we have access to a vast network of suppliers and resources. This allows us to consistently deliver high-quality products and services to our customers in Sri Lanka.

Whether you are a small business or a large corporation, we are dedicated to providing you with a seamless procurement experience. Our team is committed to building long-term relationships based on trust, reliability, and customer satisfaction.

Contact us today to discuss your requirements for Electrolytic Tinplate Coils in Sri Lanka. We look forward to partnering with you and contributing to the success of your projects.