All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

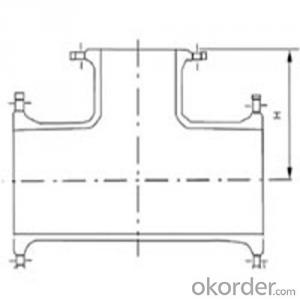

What is the function of a ductile iron mechanical joint gland follower and how is it installed?

The function of a ductile iron mechanical joint gland follower is to provide a secure and leak-proof connection between two pipes in a pipeline system. It is typically used in water and wastewater applications.

To install a ductile iron mechanical joint gland follower, the following steps are generally followed:

1. First, ensure that the pipe ends are clean and free from any debris or contaminants.

2. Apply a lubricant or pipe joint compound to the gasket groove of the gland follower and the pipe ends to facilitate easy assembly and create a watertight seal.

3. Align the gland follower with the pipe ends and slide it over the joint until it reaches the desired position.

4. Use a wrench or a specific tool to tighten the gland bolts evenly in a crisscross pattern, ensuring that the joint is tight and secure.

5. Repeat the process for all the gland bolts until they are fully tightened.

6. It is important to follow the manufacturer's guidelines and recommendations for torque specifications during the installation process.

7. Finally, conduct a visual inspection and perform any necessary pressure tests to ensure the joint is properly installed and leak-free.

Are ductile iron pipe fittings suitable for horizontal directional drilling?

Yes, ductile iron pipe fittings are suitable for horizontal directional drilling. They have excellent strength and durability, making them capable of withstanding the stresses and strains associated with the drilling process. Additionally, their flexibility allows for easier installation and maintenance in horizontal directional drilling projects.

Can ductile iron pipe fittings be used for high-pressure applications?

Yes, ductile iron pipe fittings can be used for high-pressure applications. Ductile iron has excellent strength and durability, making it suitable for handling high-pressure fluids or gases. The fittings are designed to withstand the rigors of high-pressure environments and are commonly used in industries such as water distribution, oil and gas, and industrial applications.

Wholesale Ductile Iron Pipe Fittings from supplier in Sri Lanka

Our team of experts is dedicated to providing excellent customer service and ensuring that our clients receive the highest quality products at competitive prices. We work closely with our customers to understand their specific requirements and offer tailored solutions to meet their needs.

Whether you are looking for standard Ductile Iron Pipe Fittings or custom-made products, we have the capabilities and resources to fulfill your demands. Our extensive network of suppliers allows us to source products from reputable manufacturers, ensuring that our customers receive only the best.

In addition to our sales and quotation services, we also provide technical support to assist our customers in selecting the right products for their projects. Our team of engineers is well-versed in the technical aspects of Ductile Iron Pipe Fittings and can offer guidance and advice on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company, which gives us access to vast resources and expertise. This enables us to provide comprehensive procurement services, ensuring that our customers have access to a wide range of products and solutions.

We take pride in our market experience in Sri Lanka and have successfully completed numerous projects in various industries, including water supply, sewage systems, and industrial applications. Our track record speaks for itself, and we are confident in our ability to contribute to the success of your projects.

If you are in need of Ductile Iron Pipe Fittings in Sri Lanka, we are your trusted partner. Contact us today to discuss your requirements and let us help you find the perfect solution for your needs.

Whether you are looking for standard Ductile Iron Pipe Fittings or custom-made products, we have the capabilities and resources to fulfill your demands. Our extensive network of suppliers allows us to source products from reputable manufacturers, ensuring that our customers receive only the best.

In addition to our sales and quotation services, we also provide technical support to assist our customers in selecting the right products for their projects. Our team of engineers is well-versed in the technical aspects of Ductile Iron Pipe Fittings and can offer guidance and advice on installation, maintenance, and troubleshooting.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company, which gives us access to vast resources and expertise. This enables us to provide comprehensive procurement services, ensuring that our customers have access to a wide range of products and solutions.

We take pride in our market experience in Sri Lanka and have successfully completed numerous projects in various industries, including water supply, sewage systems, and industrial applications. Our track record speaks for itself, and we are confident in our ability to contribute to the success of your projects.

If you are in need of Ductile Iron Pipe Fittings in Sri Lanka, we are your trusted partner. Contact us today to discuss your requirements and let us help you find the perfect solution for your needs.

Hot Search

- Ductile Iron Pipes in Liberia

- Ductile Iron Pipe Fittings in British

- Ductile Iron Pipe Fittings in Malawi

- Ductile Iron Pipe Fittings in India

- Ductile Iron Pipe Fittings in Botswana

- Ductile Iron Pipe Fittings in Albania

- Ductile Iron Pipe Fittings in Australia

- Ductile Iron Pipes in Kiribati

- Ductile Iron Pipe Fittings in Guatemala

- Ductile Iron Pipe Fittings in United Arab Emirates