All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

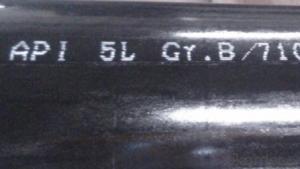

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel pipes used in the construction of pipelines for natural gas transmission?

Steel pipes are commonly used in the construction of pipelines for natural gas transmission due to their durability and strength. These pipes are welded together to form a continuous and secure pipeline that can withstand high pressure and extreme environmental conditions. The steel material is resistant to corrosion and can safely transport natural gas over long distances. Additionally, steel pipes can be easily laid underground or aboveground, making them a cost-effective and efficient choice for natural gas transmission infrastructure.

What are the design principles for steel pipes used in high-pressure hydraulic and pneumatic systems in industrial machinery?

The design principles for steel pipes used in high-pressure hydraulic and pneumatic systems in industrial machinery involve factors like material selection, wall thickness, and joint integrity. These pipes should be made of high-strength steel to withstand the high pressure and provide durability. The wall thickness should be carefully chosen to ensure the pipe can handle the required pressure without deformation or failure. Additionally, proper joint design and construction techniques are essential to maintain the integrity and prevent leakage in these systems.

How do steel pipes contribute to the construction of high-rise buildings and skyscrapers?

Steel pipes are essential in the construction of high-rise buildings and skyscrapers due to their strength, durability, and versatility. They are commonly used for structural support, allowing for the creation of tall and stable structures. Steel pipes can withstand heavy loads and are resistant to strong winds, ensuring the stability and safety of these buildings. Additionally, they are often used for plumbing and mechanical systems, providing efficient water supply and ventilation throughout the structure. Overall, steel pipes play a crucial role in the construction of high-rise buildings and skyscrapers by providing the necessary strength and functionality required for these impressive structures.

How do you determine the appropriate size of a steel pipe for a specific application?

To determine the appropriate size of a steel pipe for a specific application, several factors need to be considered. These include the fluid or gas being transported, the required flow rate, pressure and temperature conditions, as well as the overall system design and any regulatory requirements. Calculations such as fluid dynamics, pressure drop, and pipe sizing equations are commonly used to assess the dimensions of the pipe, ensuring it can handle the intended conditions while minimizing energy losses and maintaining safety standards. Consulting engineering guidelines, standards, and industry best practices is also essential to ensure accurate sizing for an efficient and reliable pipe system.

Wholesale Steel Pipes from supplier in Rwanda

Whether you require steel pipes for construction, infrastructure development, or industrial applications, we have you covered. Our range includes seamless pipes, welded pipes, galvanized pipes, and more, all meeting international quality standards.

We understand the unique challenges of the Rwandan market and can offer customized solutions to meet your specific requirements. Our team of experts is well-versed in local regulations and can guide you through the procurement process, ensuring compliance and timely delivery.

In addition to supplying high-quality steel pipes, we also provide value-added services such as pipe cutting, threading, and coating. Our state-of-the-art facilities and advanced equipment enable us to meet your precise specifications and deliver superior products.

At CNBM Rwanda, we prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability. Our dedicated customer support team is available to assist you at every step, from product selection to after-sales service.

Partner with us for all your steel pipe needs in Rwanda and experience the CNBM difference. Contact us today to discuss your requirements and learn how we can contribute to the success of your projects.

We understand the unique challenges of the Rwandan market and can offer customized solutions to meet your specific requirements. Our team of experts is well-versed in local regulations and can guide you through the procurement process, ensuring compliance and timely delivery.

In addition to supplying high-quality steel pipes, we also provide value-added services such as pipe cutting, threading, and coating. Our state-of-the-art facilities and advanced equipment enable us to meet your precise specifications and deliver superior products.

At CNBM Rwanda, we prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability. Our dedicated customer support team is available to assist you at every step, from product selection to after-sales service.

Partner with us for all your steel pipe needs in Rwanda and experience the CNBM difference. Contact us today to discuss your requirements and learn how we can contribute to the success of your projects.