All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

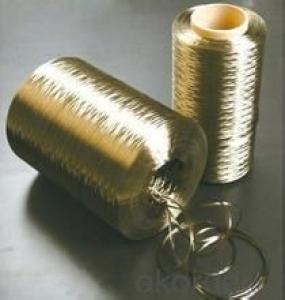

What are the different surface finishes available in fiberglass roving?

There are several different surface finishes available in fiberglass roving, including silane sizing, epoxy sizing, polyester sizing, and polyurethane sizing. Each of these finishes offers specific properties and benefits, such as improved adhesion, chemical resistance, or enhanced mechanical strength, depending on the intended application of the fiberglass roving.

What are the different curing options for fiberglass roving?

The different curing options for fiberglass roving include heat curing, chemical curing, and UV curing. Heat curing involves applying heat to the roving to initiate a chemical reaction and harden the resin. Chemical curing involves using a catalyst or activator to trigger the curing process. UV curing utilizes ultraviolet light to cure the roving by exposing it to UV radiation.

Can fiberglass roving be used in the production of electrical circuit boards?

No, fiberglass roving cannot be used in the production of electrical circuit boards. Circuit boards are typically made using materials like epoxy resin and copper, not fiberglass.

Wholesale Fiberglass Roving from supplier in Nepal

At our company, we prioritize quality and reliability in all aspects of our operations. Our Fiberglass Roving products are manufactured using advanced technology and adhere to strict quality control standards. We work closely with our customers to understand their specific needs and provide tailored solutions that meet their requirements.

In addition to our sales and technical support services, we also offer comprehensive after-sales support. Our team of experts is available to assist with any technical queries or issues that may arise. We believe in building strong relationships with our customers and ensuring their satisfaction throughout their experience with us.

Furthermore, as a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and innovations, ensuring that we can provide our customers with the latest and most advanced Fiberglass Roving products.

We understand the importance of sustainability and environmental responsibility. Our Fiberglass Roving products are manufactured with eco-friendly practices and materials, minimizing their impact on the environment. We are committed to promoting sustainable development in Nepal and aim to contribute to a greener future.

In conclusion, if you are looking for a reliable supplier of Fiberglass Roving products in Nepal, look no further. Our extensive range of high-quality products, combined with our exceptional customer service and technical support, make us the ideal partner for all your Fiberglass Roving needs. Contact us today to discuss how we can assist you in achieving your project goals in Nepal.

In addition to our sales and technical support services, we also offer comprehensive after-sales support. Our team of experts is available to assist with any technical queries or issues that may arise. We believe in building strong relationships with our customers and ensuring their satisfaction throughout their experience with us.

Furthermore, as a subsidiary of CNBM, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and innovations, ensuring that we can provide our customers with the latest and most advanced Fiberglass Roving products.

We understand the importance of sustainability and environmental responsibility. Our Fiberglass Roving products are manufactured with eco-friendly practices and materials, minimizing their impact on the environment. We are committed to promoting sustainable development in Nepal and aim to contribute to a greener future.

In conclusion, if you are looking for a reliable supplier of Fiberglass Roving products in Nepal, look no further. Our extensive range of high-quality products, combined with our exceptional customer service and technical support, make us the ideal partner for all your Fiberglass Roving needs. Contact us today to discuss how we can assist you in achieving your project goals in Nepal.