All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you ensure the compatibility of accessories and connectors with aluminum profiles for reliable project execution?

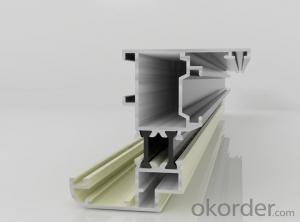

To ensure the compatibility of accessories and connectors with aluminum profiles for reliable project execution, it is essential to follow certain steps. Firstly, it is important to thoroughly understand the specifications and requirements of the project. This includes considering the load-bearing capacity, dimensions, and specific design needs of the aluminum profiles.

Secondly, it is crucial to choose accessories and connectors that are specifically designed for use with aluminum profiles. This ensures proper fit and compatibility, minimizing the risk of any functionality or structural issues. It is advisable to consult with manufacturers or suppliers who specialize in aluminum profile systems to ensure the right selection of compatible accessories and connectors.

Additionally, conducting thorough testing and quality assurance checks before project execution is vital. This involves physically testing the compatibility of accessories and connectors with the aluminum profiles to ensure they function seamlessly together. It may also be helpful to seek expert advice or consult with engineers to ensure the reliability and compatibility of the chosen components.

Overall, by understanding project requirements, selecting compatible components, and conducting rigorous testing, the compatibility of accessories and connectors with aluminum profiles can be ensured, leading to a reliable and successful project execution.

What are the different fastening methods for securing accessories and components to aluminum profiles?

There are several fastening methods for securing accessories and components to aluminum profiles. Some common methods include using T-nuts and bolts, slide-in nuts, panel clips, adhesive tapes, and self-tapping screws. These methods provide a secure and versatile way to attach various accessories and components to aluminum profiles.

What are the common challenges in recycling aluminum profiles efficiently?

Some common challenges in recycling aluminum profiles efficiently include the removal of contaminants such as coatings or paints, sorting different alloys, and managing the energy-intensive process of melting and reshaping the aluminum. Additionally, the collection and transportation of aluminum profiles can be a logistical challenge, as well as ensuring a steady supply of quality material for recycling.

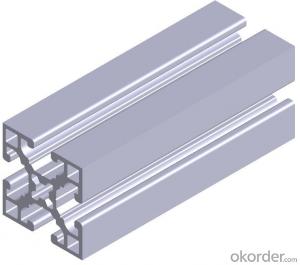

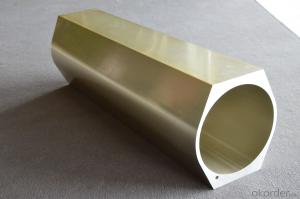

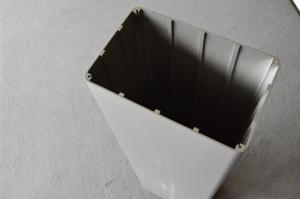

Wholesale Aluminum Profiles from supplier in Namibia

Whether you are in need of standard or customized Aluminum Profiles, we have a wide range of options to cater to your specific requirements. Our team of experienced professionals is dedicated to providing excellent customer service and ensuring that you receive the highest quality products.

We understand the importance of timely and efficient delivery, which is why we work closely with reliable logistics partners to ensure that your Aluminum Profiles are delivered to your doorstep in a timely manner. Our efficient inventory management system allows us to maintain adequate stock levels, ensuring that you have access to the products you need when you need them.

In addition to supplying Aluminum Profiles, we also offer comprehensive technical support services. Our team of experts is available to assist you with any technical queries or challenges you may encounter. Whether you need assistance with installation, design, or troubleshooting, we are here to help.

Furthermore, as a subsidiary platform of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide you with a competitive advantage in terms of pricing, quality, and service.

We are committed to building long-term relationships with our clients and strive to exceed their expectations. Contact us today to discuss your Aluminum Profiles needs in Namibia and let us provide you with the best solutions for your projects.

We understand the importance of timely and efficient delivery, which is why we work closely with reliable logistics partners to ensure that your Aluminum Profiles are delivered to your doorstep in a timely manner. Our efficient inventory management system allows us to maintain adequate stock levels, ensuring that you have access to the products you need when you need them.

In addition to supplying Aluminum Profiles, we also offer comprehensive technical support services. Our team of experts is available to assist you with any technical queries or challenges you may encounter. Whether you need assistance with installation, design, or troubleshooting, we are here to help.

Furthermore, as a subsidiary platform of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to provide you with a competitive advantage in terms of pricing, quality, and service.

We are committed to building long-term relationships with our clients and strive to exceed their expectations. Contact us today to discuss your Aluminum Profiles needs in Namibia and let us provide you with the best solutions for your projects.