All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

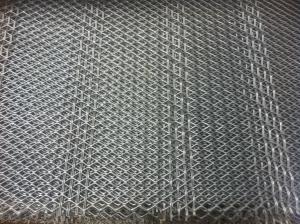

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the significance of surface preparation and coatings in protecting steel pipes from corrosion?

Surface preparation and coatings play a crucial role in protecting steel pipes from corrosion. By removing any existing corrosion, dirt, and contaminants from the surface, proper surface preparation ensures a clean and smooth surface for the coating to adhere to. This improves the coating's effectiveness and longevity in providing a protective barrier against corrosive elements. Additionally, coatings act as a physical barrier, preventing direct contact between the steel surface and corrosive agents, such as moisture and chemicals, thus reducing the risk of corrosion. Overall, surface preparation and coatings are essential in enhancing the durability and lifespan of steel pipes by preventing or minimizing corrosion.

What are the design considerations for steel pipe systems used in power generation plants?

Some of the key design considerations for steel pipe systems used in power generation plants include:

1. Material Selection: Choosing the right type of steel that can withstand high temperatures, pressures, and corrosive environments is crucial. Alloyed steel with high tensile strength and resistance to corrosion is often preferred.

2. Pressure and Temperature Ratings: Power generation plants typically operate at high pressures and temperatures. Therefore, the steel pipes must be designed to handle these conditions safely without any risk of failure or leakage.

3. Pipe Sizing and Layout: Proper sizing and layout of the pipe system are important to ensure efficient flow of fluids or gases throughout the plant. Considerations such as pressure drop, flow rates, and accessibility for maintenance and repairs should be taken into account.

4. Support and Anchoring: The weight of the steel pipes and the fluids they carry can be substantial. Proper support and anchoring systems are essential to prevent sagging, excessive stress, or vibration that could lead to pipe failure.

5. Corrosion Protection: Power generation plants often have corrosive environments due to the presence of chemicals or high-temperature steam. Applying protective coatings or using corrosion-resistant materials can help extend the lifespan of the steel pipes and minimize maintenance.

6. Expansion and Contraction: Steel pipes can expand or contract due to temperature changes. Proper consideration must be given to factors such as thermal expansion joints or compensators to accommodate these movements and prevent stress or damage.

7. Safety and Regulatory Compliance: Power generation plants are subject to various safety codes and regulations. Design considerations should ensure compliance with these standards to ensure the safety of personnel and the environment.

Overall, the design of steel pipe systems for power generation plants must prioritize durability, efficiency, safety, and compliance with industry standards to ensure reliable and uninterrupted operation of the plant.

What is the role of steel pipes in the aerospace industry for aircraft engine components?

Steel pipes play a crucial role in the aerospace industry for aircraft engine components. They are used for various purposes such as fuel lines, hydraulic systems, and pneumatic systems. Steel pipes provide structural integrity, durability, and resistance to high temperatures and pressures, making them ideal for carrying fluids and gases within the engine. They also help ensure efficient fuel delivery and assist in maintaining the overall performance and safety of the aircraft engine.

How are steel pipes used in the mining industry?

Steel pipes are commonly used in the mining industry for various purposes such as transporting fluids, slurries, and gases, as well as providing structural support for underground mines. They are used in the construction of mine shafts, tunnels, and piping systems for the extraction, processing, and transportation of minerals. Steel pipes are durable, resistant to corrosion, and capable of withstanding high pressure and extreme conditions, making them essential for efficient and safe mining operations.

Wholesale Steel Pipes from supplier in Kiribati

Whether you require steel pipes for construction, infrastructure, or industrial applications, we have a wide variety of options to suit your specific requirements. Our steel pipes are sourced from reputable manufacturers and meet international quality standards, ensuring durability and reliability.

We understand the importance of timely delivery and strive to provide efficient logistics solutions to ensure your projects run smoothly. Our team of experts is available to assist you with product selection, technical specifications, and any other queries you may have.

With our strong global network and extensive industry knowledge, we are able to offer competitive pricing without compromising on quality. We aim to build long-term partnerships with our clients by providing excellent customer service and exceeding their expectations.

Contact us today to discuss your steel pipes requirements in Kiribati and let us provide you with the best solutions for your projects.

We understand the importance of timely delivery and strive to provide efficient logistics solutions to ensure your projects run smoothly. Our team of experts is available to assist you with product selection, technical specifications, and any other queries you may have.

With our strong global network and extensive industry knowledge, we are able to offer competitive pricing without compromising on quality. We aim to build long-term partnerships with our clients by providing excellent customer service and exceeding their expectations.

Contact us today to discuss your steel pipes requirements in Kiribati and let us provide you with the best solutions for your projects.