All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the significance of coil packaging and banding for secure transportation in the energy and utilities sector?

Coil packaging and banding play a crucial role in ensuring secure transportation within the energy and utilities sector. Coils, which are often large and heavy, are commonly used in this industry for various applications such as power generation and transmission equipment. Properly packaging and banding these coils is essential to prevent damage during transportation, as any mishap can result in costly downtime and delays in energy production.

By securely packaging coils, they are protected from external factors like moisture, dust, and impact that could potentially compromise their integrity. This is particularly important for sensitive equipment like transformers and generators, which require utmost care to maintain their functionality. Additionally, banding the coils tightly helps to prevent any shifting or movement during transit, reducing the risk of accidents or damage to the surrounding infrastructure.

Moreover, coil packaging and banding are essential for ensuring worker safety. The energy and utilities sector often involves handling heavy equipment, and improperly secured coils can pose a significant risk to the personnel involved in transportation and installation. Proper packaging and banding techniques minimize the chances of accidents, injuries, and even fatalities, thereby prioritizing the well-being of employees.

Overall, coil packaging and banding hold great significance in the energy and utilities sector, as they ensure the safe and secure transportation of valuable equipment, maintain operational efficiency, and protect both assets and personnel.

What is the role of tension control in coil winding and unwinding for HVAC systems and components?

The role of tension control in coil winding and unwinding for HVAC systems and components is crucial for ensuring consistent and uniform winding or unwinding of coils. Tension control helps in maintaining the appropriate level of tension throughout the winding process, preventing issues such as over-tensioning or under-tensioning of the coils. This is important as it ensures the coils are properly formed and wound, which in turn affects the overall performance and efficiency of the HVAC system or component. Additionally, proper tension control prevents coil damage, tangling, or misalignment, leading to improved product quality and reliability.

How are steel coils prepared for the production of electrical conduit?

Steel coils are prepared for the production of electrical conduit by undergoing several key steps. First, the coils are uncoiled and straightened to ensure they are in the proper form for further processing. Then, the steel is cleaned to remove any impurities or contaminants that could affect the quality of the final product. After cleaning, the steel is shaped and formed into the desired conduit size using specialized machinery and techniques. Finally, the coils are cut into individual lengths and further processed to meet specific requirements such as threading or coating, before being ready for use in electrical conduit production.

What is the typical width of steel coils?

The typical width of steel coils can vary depending on the specific application and industry. However, it is common for steel coils to have widths ranging from 600mm to 2,000mm or more.

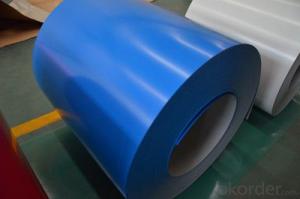

Wholesale Steel Coils from supplier in Kazakhstan

We understand the unique requirements of the Kazakhstan market and can assist you in selecting the right Steel Coils that meet your specific needs. Our team of experts is well-versed in the local regulations and industry standards, ensuring that our products comply with all necessary requirements.

Whether you are looking for hot-rolled coils, cold-rolled coils, galvanized coils, or any other type of Steel Coils, we have a wide range of options available. Our products are sourced from trusted manufacturers and undergo rigorous quality control checks to ensure their durability and reliability.

In addition to supplying Steel Coils, we also offer competitive pricing, timely delivery, and excellent after-sales service. Our dedicated sales team is available to provide you with quick and accurate quotations, ensuring that you receive the best possible prices for your requirements.

Moreover, our technical support team is always ready to assist you with any queries or concerns you may have. We can provide technical specifications, product recommendations, and installation guidance to help you make informed decisions for your projects.

As a subsidiary platform of CNBM, we have access to a vast network of resources and partnerships, allowing us to offer you a comprehensive one-stop procurement solution. We can handle all aspects of your Steel Coils procurement process, from sourcing and logistics to documentation and customs clearance.

With our years of experience in the Kazakhstan market, we have developed strong relationships with local suppliers and have a deep understanding of the market dynamics. This enables us to provide valuable insights and guidance to help you navigate the challenges and maximize the opportunities in the Kazakhstan steel industry.

Partnering with us means you can rely on a trusted and dependable supplier for all your Steel Coils needs in Kazakhstan. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

Whether you are looking for hot-rolled coils, cold-rolled coils, galvanized coils, or any other type of Steel Coils, we have a wide range of options available. Our products are sourced from trusted manufacturers and undergo rigorous quality control checks to ensure their durability and reliability.

In addition to supplying Steel Coils, we also offer competitive pricing, timely delivery, and excellent after-sales service. Our dedicated sales team is available to provide you with quick and accurate quotations, ensuring that you receive the best possible prices for your requirements.

Moreover, our technical support team is always ready to assist you with any queries or concerns you may have. We can provide technical specifications, product recommendations, and installation guidance to help you make informed decisions for your projects.

As a subsidiary platform of CNBM, we have access to a vast network of resources and partnerships, allowing us to offer you a comprehensive one-stop procurement solution. We can handle all aspects of your Steel Coils procurement process, from sourcing and logistics to documentation and customs clearance.

With our years of experience in the Kazakhstan market, we have developed strong relationships with local suppliers and have a deep understanding of the market dynamics. This enables us to provide valuable insights and guidance to help you navigate the challenges and maximize the opportunities in the Kazakhstan steel industry.

Partnering with us means you can rely on a trusted and dependable supplier for all your Steel Coils needs in Kazakhstan. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.