All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

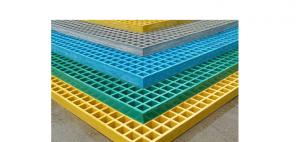

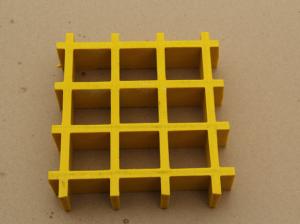

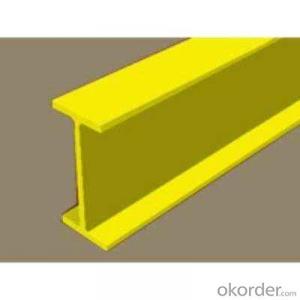

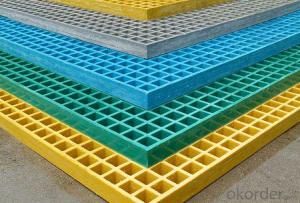

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the benefits of using FRP pultrusion profiles in infrastructure projects?

There are several benefits of using FRP (Fiber Reinforced Polymer) pultrusion profiles in infrastructure projects.

Firstly, FRP pultrusion profiles are lightweight yet strong, making them suitable for various applications without adding excessive weight to the structure. This allows for easier handling, transportation, and installation, reducing labor and equipment costs.

Secondly, FRP pultrusion profiles have excellent corrosion resistance, which is crucial in infrastructure projects exposed to harsh environments, such as bridges, marine structures, and wastewater treatment plants. Unlike traditional materials like steel, FRP does not rust or corrode, resulting in longer service life and lower maintenance costs.

Additionally, FRP pultrusion profiles offer high strength-to-weight ratio, providing structural integrity while minimizing material usage. This attribute is particularly advantageous in large-scale projects, where the reduction of material costs can lead to significant savings.

Moreover, FRP pultrusion profiles are non-conductive and non-magnetic, making them ideal for projects where electrical or magnetic interference needs to be minimized. This feature is especially beneficial in applications such as electrical transmission towers or MRI rooms.

Furthermore, FRP pultrusion profiles are highly durable and resistant to UV radiation, chemicals, and environmental factors. They have excellent dimensional stability and can withstand extreme temperatures, making them suitable for both indoor and outdoor applications with reduced risk of degradation over time.

Overall, the benefits of using FRP pultrusion profiles in infrastructure projects include lightweight design, corrosion resistance, high strength-to-weight ratio, non-conductivity, durability, and dimensional stability. These attributes contribute to cost savings, improved performance, and increased longevity of the structures.

Can FRP pultrusion profiles be used in cooling towers?

Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in cooling towers. FRP pultrusion profiles offer excellent resistance to corrosion, making them ideal for use in cooling tower applications where exposure to water and chemicals is common. Additionally, FRP pultrusion profiles are lightweight, strong, and durable, providing reliable structural support and reducing maintenance requirements.

Are FRP pultrusion profiles conductive?

No, FRP pultrusion profiles are not conductive.

Wholesale FRP Pultrusion Profiles from supplier in Kazakhstan

We understand the unique demands and challenges of the Kazakhstan market, and our team of experts is committed to delivering tailored solutions to meet your specific needs. Our FRP Pultrusion Profiles are manufactured using high-quality materials and advanced technology, ensuring exceptional durability and performance.

In addition to our wide range of products, we offer comprehensive services to support your procurement process. Our dedicated sales team is available to assist you with product selection, offer competitive quotations, and provide technical support throughout your project. We understand the importance of timely delivery, and our efficient logistics network ensures prompt and reliable shipment of your orders.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and a global network. This enables us to offer competitive pricing, reliable quality control, and access to the latest industry trends and innovations. Our commitment to customer satisfaction is paramount, and we strive to exceed your expectations in every aspect of our service.

Whether you are in need of FRP Pultrusion Profiles for construction, infrastructure, or industrial applications, we have the expertise and capabilities to meet your requirements. Contact us today to discuss your project needs and let us demonstrate why we are the preferred choice for FRP Pultrusion Profiles in Kazakhstan.

In addition to our wide range of products, we offer comprehensive services to support your procurement process. Our dedicated sales team is available to assist you with product selection, offer competitive quotations, and provide technical support throughout your project. We understand the importance of timely delivery, and our efficient logistics network ensures prompt and reliable shipment of your orders.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to vast resources and a global network. This enables us to offer competitive pricing, reliable quality control, and access to the latest industry trends and innovations. Our commitment to customer satisfaction is paramount, and we strive to exceed your expectations in every aspect of our service.

Whether you are in need of FRP Pultrusion Profiles for construction, infrastructure, or industrial applications, we have the expertise and capabilities to meet your requirements. Contact us today to discuss your project needs and let us demonstrate why we are the preferred choice for FRP Pultrusion Profiles in Kazakhstan.

Hot Search

- Fiberglass Chopped Strand in Rwanda

- Fiberglass Mesh Cloth in Palau

- Composite Pipes in Hungary

- FRP Pultrusion Profiles in Turkmenistan

- Fiberglass Mat Tissue in Bhutan

- Fiberglass Fabrics in Denmark

- Fiberglass Mesh in Uzbekistan

- Composite Tank in Kazakhstan

- Fiberglass Mesh tape in Samoa

- Polymer in Spain