All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are polymers recycled and disposed of?

Polymers can be recycled through various methods such as mechanical recycling, chemical recycling, and energy recovery. In mechanical recycling, the polymers are sorted, cleaned, melted, and reprocessed into new products. Chemical recycling involves breaking down the polymers into their original monomers or converting them into other useful chemicals. Energy recovery involves incinerating the polymers to generate heat or electricity. However, if recycling is not feasible, polymers can be disposed of in landfills, where they may take a long time to decompose.

What are the different methods of polymer characterization?

There are several methods used for polymer characterization, including spectroscopy techniques such as infrared (IR), nuclear magnetic resonance (NMR), and ultraviolet-visible (UV-Vis) spectroscopy. Other methods include thermal analysis techniques like differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), as well as rheological measurements to study polymer flow behavior. Additionally, size exclusion chromatography (SEC) and gel permeation chromatography (GPC) are commonly employed for determining molecular weight distribution and polymer structure.

What are the advantages of using polymers in optical fiber applications?

The advantages of using polymers in optical fiber applications include their flexibility, lightweight nature, and ease of manufacturing. Polymers can be easily molded into various shapes and sizes, making them suitable for various optical fiber designs. Additionally, polymers have low transmission losses and high light transmission capabilities, making them ideal for efficient signal transmission. Moreover, polymers are cost-effective compared to traditional glass fibers, making them more accessible for various applications.

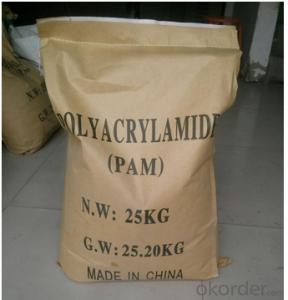

Wholesale Polymer from supplier in Haiti

Whether you are in need of PVC, PET, PP, or any other type of Polymer, we have a wide selection of high-quality products to meet your specific requirements. Our team of experts will work closely with you to understand your needs and suggest the most suitable Polymer solution for your project.

In addition to our sales services, we also provide detailed quotations that include competitive pricing and transparent cost breakdowns. We understand the importance of budgeting and will work with you to ensure that you receive the best value for your investment.

Furthermore, our technical support team is available to assist you throughout the procurement process. Whether you have questions about product specifications, application guidelines, or any other technical aspect, we are here to provide you with the necessary information and guidance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This enables us to offer you reliable and consistent supply of high-quality Polymers, ensuring that your projects are not delayed due to material shortages.

At our core, we are committed to building long-term partnerships with our clients in Haiti. We understand the unique challenges and requirements of the market and leverage our years of experience to provide you with tailored solutions. Our goal is to become your trusted Polymer supplier, supporting your success and growth in the Haitian market.

Contact us today to discuss your Polymer needs and experience the benefits of partnering with a reliable and knowledgeable supplier in Haiti.

In addition to our sales services, we also provide detailed quotations that include competitive pricing and transparent cost breakdowns. We understand the importance of budgeting and will work with you to ensure that you receive the best value for your investment.

Furthermore, our technical support team is available to assist you throughout the procurement process. Whether you have questions about product specifications, application guidelines, or any other technical aspect, we are here to provide you with the necessary information and guidance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This enables us to offer you reliable and consistent supply of high-quality Polymers, ensuring that your projects are not delayed due to material shortages.

At our core, we are committed to building long-term partnerships with our clients in Haiti. We understand the unique challenges and requirements of the market and leverage our years of experience to provide you with tailored solutions. Our goal is to become your trusted Polymer supplier, supporting your success and growth in the Haitian market.

Contact us today to discuss your Polymer needs and experience the benefits of partnering with a reliable and knowledgeable supplier in Haiti.

Hot Search

- Fiberglass Chopped Strand in South Korea

- Fiberglass Mesh Cloth in Rwanda

- Composite Pipes in Jordan

- FRP Pultrusion Profiles in Ecuador

- Fiberglass Mat Tissue in Greece

- Fiberglass Fabrics in Vanuatu

- Fiberglass Mesh in Kazakhstan

- Composite Tank in Belize

- Fiberglass Mesh tape in Ghana

- Polymer in Maldives