All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

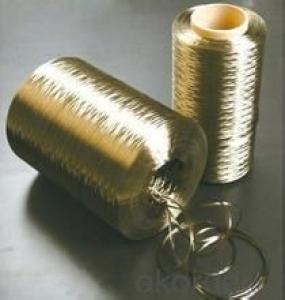

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different fiber alignments available in fiberglass roving?

The different fiber alignments available in fiberglass roving include parallel, random, and chopped strand.

How does the diameter of fiberglass roving affect its strength?

The diameter of fiberglass roving directly affects its strength. Generally, a thicker diameter of fiberglass roving tends to result in higher strength. This is because a larger diameter allows for more fibers to be present in the roving, increasing its overall strength and resistance to breakage. Conversely, a thinner diameter of roving may have fewer fibers, leading to reduced strength.

How is fiberglass roving used in the manufacturing of electrical switches?

Fiberglass roving is commonly used in the manufacturing of electrical switches to reinforce the plastic components. It is typically added to the plastic resin during the molding process to increase the overall strength and durability of the switch. The fiberglass roving helps to prevent breakage and improve the resistance to heat, electrical currents, and other external factors, ensuring a reliable and long-lasting electrical switch.

Wholesale Fiberglass Roving from supplier in Haiti

Our team of experts is well-versed in the application and usage of Fiberglass Roving in various industries, including construction, automotive, aerospace, and marine. Whether you need Fiberglass Roving for reinforcement purposes or for insulation, we have the perfect solution for your specific needs.

In addition to our wide range of products, we also offer competitive pricing and flexible delivery options to ensure that you can meet your project deadlines without any hassle. Our sales team is always available to provide you with personalized guidance and assistance, helping you choose the right Fiberglass Roving products for your project.

Furthermore, we understand the importance of timely and accurate quotations. Our dedicated quotation team ensures that you receive prompt and detailed quotations, tailored to your specific requirements. We strive to provide you with transparent pricing and clear breakdowns of costs, so you can make informed decisions.

Technical support is another key aspect of our services. Our experienced technicians are available to provide you with technical guidance and troubleshooting solutions to ensure that you achieve optimal results with our Fiberglass Roving products. We are committed to helping you overcome any challenges you may face during the application process.

When you choose us as your Fiberglass Roving supplier in Haiti, you can expect not only top-quality products but also reliable and efficient services. We prioritize customer satisfaction and strive to build long-lasting relationships with our clients.

Contact us today to discuss your Fiberglass Roving requirements in Haiti and let us help you achieve success in your projects.

In addition to our wide range of products, we also offer competitive pricing and flexible delivery options to ensure that you can meet your project deadlines without any hassle. Our sales team is always available to provide you with personalized guidance and assistance, helping you choose the right Fiberglass Roving products for your project.

Furthermore, we understand the importance of timely and accurate quotations. Our dedicated quotation team ensures that you receive prompt and detailed quotations, tailored to your specific requirements. We strive to provide you with transparent pricing and clear breakdowns of costs, so you can make informed decisions.

Technical support is another key aspect of our services. Our experienced technicians are available to provide you with technical guidance and troubleshooting solutions to ensure that you achieve optimal results with our Fiberglass Roving products. We are committed to helping you overcome any challenges you may face during the application process.

When you choose us as your Fiberglass Roving supplier in Haiti, you can expect not only top-quality products but also reliable and efficient services. We prioritize customer satisfaction and strive to build long-lasting relationships with our clients.

Contact us today to discuss your Fiberglass Roving requirements in Haiti and let us help you achieve success in your projects.