All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

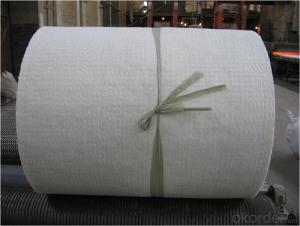

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common testing methods for refractory materials?

The common testing methods for refractory materials include thermal conductivity testing, thermal expansion testing, abrasion resistance testing, compression testing, and chemical analysis.

How do refractory materials affect the efficiency of heat treatment processes?

Refractory materials play a crucial role in heat treatment processes by providing insulation and maintaining high temperatures. These materials have high melting points and low thermal conductivity, which allows them to withstand extreme heat without significant degradation. By efficiently containing and reflecting heat, refractory materials prevent heat loss and ensure uniform heating, improving the overall efficiency of heat treatment processes.

How are refractory castables installed?

Refractory castables are typically installed by mixing the castable material with water to form a workable consistency. This mixture is then poured or gunned into the desired area using specialized equipment or hand tools. The castable is then allowed to dry and cure, usually through a controlled heat treatment process, to achieve its full strength and performance.

What are the challenges faced by refractory materials in the electronics industry?

One of the key challenges faced by refractory materials in the electronics industry is their ability to withstand high temperatures. Electronic devices generate a significant amount of heat, and refractory materials need to be able to maintain their structural integrity and performance under these extreme conditions. Another challenge is the need for refractory materials to have excellent electrical insulation properties to prevent any electrical leakage or short-circuiting. Additionally, refractory materials should be chemically inert to resist corrosion from various chemicals used in electronic processes. The materials should also have low thermal conductivity to minimize heat transfer and ensure efficient operation of electronic devices. Lastly, the cost-effectiveness and availability of refractory materials can also be a challenge in the electronics industry, as they need to meet performance requirements while being economically viable for large-scale production.

Wholesale Refractory Materials from supplier in Guatemala

Our team of experts is dedicated to understanding your specific needs and providing customized solutions for your refractory material requirements. We offer a wide range of refractory products, including bricks, castables, mortars, and insulation materials, sourced from trusted manufacturers worldwide.

In addition to supplying high-quality materials, we also offer comprehensive sales and technical support services. Our experienced sales team will assist you in selecting the right products for your project, ensuring that you receive the best value for your investment. We provide detailed quotations, taking into consideration factors such as quantity, delivery timelines, and project requirements.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire project lifecycle. Whether you need help with installation, troubleshooting, or maintenance, our experts will be there to support you every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong and reliable organization. This enables us to offer competitive pricing, efficient logistics, and a robust supply chain network. We strive to deliver your refractory materials on time and in the most cost-effective manner possible.

With our extensive product range, project expertise, and all-in-one procurement services, we are your trusted partner for all your refractory material needs in Guatemala. Contact us today to discuss your requirements and experience the quality and reliability that we have to offer.

In addition to supplying high-quality materials, we also offer comprehensive sales and technical support services. Our experienced sales team will assist you in selecting the right products for your project, ensuring that you receive the best value for your investment. We provide detailed quotations, taking into consideration factors such as quantity, delivery timelines, and project requirements.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire project lifecycle. Whether you need help with installation, troubleshooting, or maintenance, our experts will be there to support you every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong and reliable organization. This enables us to offer competitive pricing, efficient logistics, and a robust supply chain network. We strive to deliver your refractory materials on time and in the most cost-effective manner possible.

With our extensive product range, project expertise, and all-in-one procurement services, we are your trusted partner for all your refractory material needs in Guatemala. Contact us today to discuss your requirements and experience the quality and reliability that we have to offer.

Hot Search

- Monolithic Refractories in Eritrea

- Ceramic Fiber Products in Mongolia

- Refractory Bricks in Turkey

- Raw Materials For Refractory in Ecuador

- Ceramic Fiber Products in Malaysia

- Raw Materials For Refractory in Greece

- Monolithic Refractories in Liechtenstein

- Refractory Bricks in Haiti

- Ceramic Fiber Products in South Africa

- Ceramic Fiber Products in Ethiopia